Automated Empanada Production Line Breakthrough – Reducing Production Labor by up to 7 to 8 Personnel

ANKO developed the high-capacity EMP-3000 Empanada Making Machine based on a client’s requirements in the United States. Our team conducted an in-depth analysis of operations at the client’s facility to understand the challenges of their Empanada production. This client needed a machine that could “quickly adapt to market demands while maintaining a high-quality product output.” After multiple test runs and refinement, the ANKO EMP-3000 Empanada Making Machine was launched. This model has a capacity of producing 3,000 Empanadas per hour to help clients’ productivity while saving on labor costs. The easy-to-remove filling system enables continuous production and improves quality control, providing a competitive advantage in food manufacturing.

Empanada

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Equipment Integration to Boost Production Efficiency While Saving Time and Labor

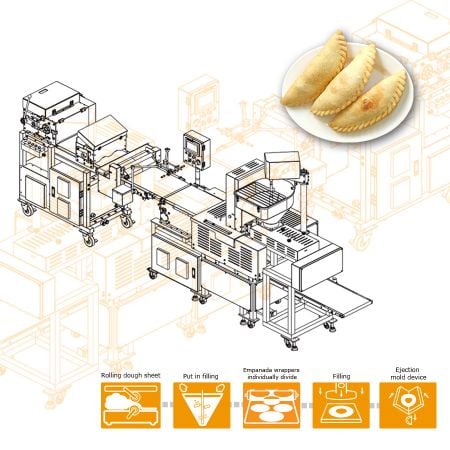

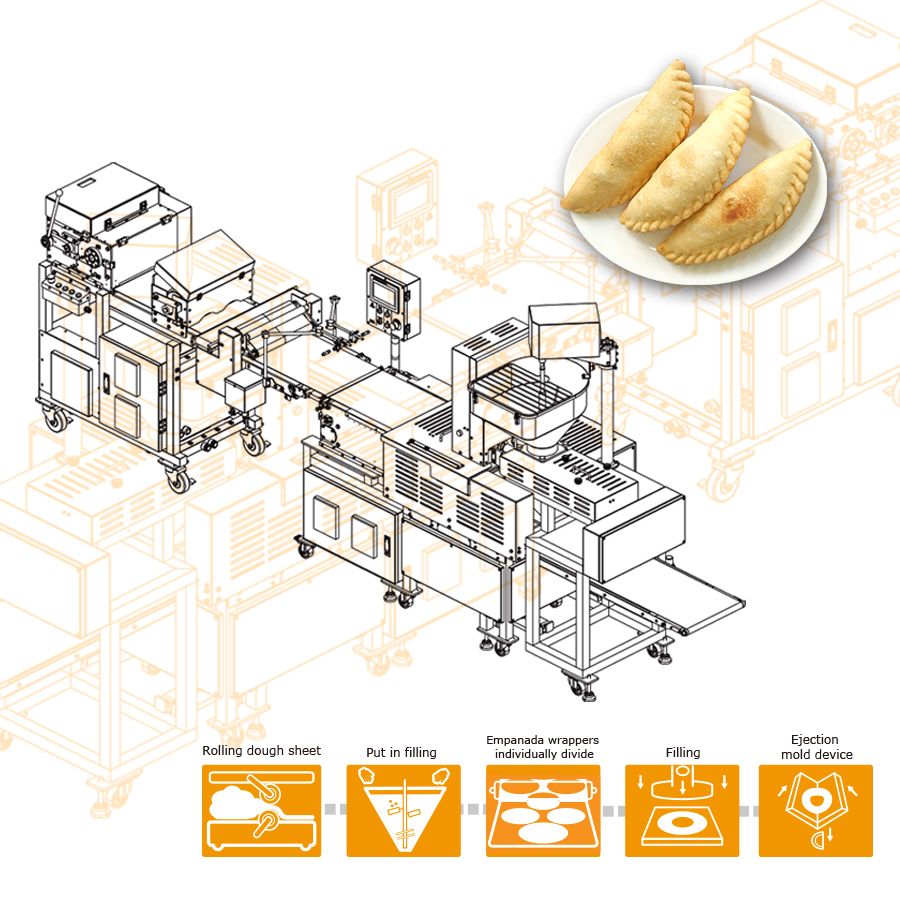

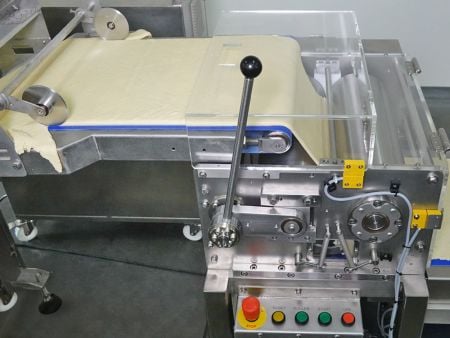

The EMP-3000 Empanada Making Machine has a built-in Dough Sheeting Machine featuring a feeding roller, sheeting roller, pressing roller, and a hand wheel for adjusting the dough thickness. These features make the production process more efficient and less labor-intensive. Customers can add specific mechanisms or use the hand wheel to adjust the dough thickness directly. For clients with dough sheeting equipment, ANKO offers a customizable Dough Belt Roller that seamlessly feeds dough sheets into the EMP-3000 to be cut, filled, and formed into Empanadas. Whether clients currently have dough production equipment, ANKO provides flexible options to meet various dough production requirements. We can also assist in planning for additional equipment, including fryers and packaging machines, to further enhance production efficiency.

Solution 2. Customized Mold Design with Enhanced Durability

ANKO’s Empanada forming molds are made with FDA-approved materials to ensure food hygiene and quality. Traditional Empanada machines use force control, forming molds that often wear out quickly; however, the EMP-3000 Empanada Making Machine uses stroke control, allowing the dual molds to press together precisely without excessive wear, significantly extending the mold’s lifespan. Additionally, customized mold designs are available to meet the client’s product requirements, including unique patterns, branded logos, or flavor indicators (e.g., “Beef” for beef Empanadas, “Chicken” for chicken Empanadas). This customization simplifies the production and sales processes and enhances brand recognition.

Solution 3. Modular Filling System: Adapts to Various Fillings, Perfectly Retains 10 mm Chunky Texture

The EMP-3000 Empanada Making Machine features a 60-liter high-capacity filling hopper, allowing for extended continuous production. It can also be paired with refill equipment to minimize the frequency of operators refilling. One key feature of this machine is its modular design; after finishing a batch with beef filling, operators can slide out the filling system and replace it with a pre-filled chicken filling system, completing the change within five minutes. This design increases production capacity during peak seasons to meet market demand. The system can process a variety of fillings, including meats, cheeses, and various vegetables. It can handle ingredients up to 10 mm pieces, such as peas, corn kernels, diced carrots, and potatoes, without overprocessing, which retains the texture, consistency, and shapes of these ingredients.

The EMP-3000 Empanada Making Machine requires a minimum of two operators to achieve a production rate of 3,000 Empanadas per hour. Production can be started in three simple steps and no prior experience required to operate this machine. ANKO can customize the production process to meet the client’s production requirements, achieving high productivity and efficiency.

Food Equipment Introduction

- Place dough and filling into separate hoppers

- Turn the switch ON

- Machine automatically carves out wrappers

- Filling extruding

- Product forming

Managing Production Details: Ensuring Machine Performance and Operational Safety

In order to reuse the dough scraps generated during the Empanada production, ANKO researched and developed a Dough Recycling System to help producers avoid food waste. After cutting pastry wrappers, the Sprinkler System lightly sprays water onto the edges to facilitate sealing. The EMP-3000 Empanada Making Machine is equipped with a CE safety guard to ensure the operator’s safety during production. The forming and filling systems are compatible with a low-pressure washer to streamline daily cleaning and maintenance procedures.

- Solution Proposal

ANKO Empanada Making Machine is Your Top Choice for Empanada Production!

ANKO did

ANKO has developed the EMP-3000 Empanada Making Machine for medium and large-scale Empanada producers. We offer an efficient production solution for food factories and high-volume manufacturing requirements. ANKO provides comprehensive services to build a custom Empanada production line, including the configuration of commercial mixers, vegetable cutting machines, meat grinders to deep fryers, packaging equipment, and X-ray inspection machines. Production solutions can also be tailored to specific workforce and spatial requirements.

ANKO can help you more

In addition to professional food machines, ANKO's consulting services are the best in the industry. ANKO will conduct a comprehensive consultation process to help clarify specific production requirements and offer production trials before your purchase. Our expert team optimizes your products' taste, appearance, and recipe. Additionally, we provide full training and after-sales support and partner with numerous global distributors ready and available to deliver localized assistance. Click to Learn More or complete the inquiry form below to receive additional information.

- Machines

-

EMP-3000

The EMP-3000 Empanada Making Machine is essential for producing Empanadas. When paired with a dough sheeting machine, the equipment automatically produces dough sheets, carves out individual wrappers, and extrudes filling to make up to 3,000 Empanadas per hour. The forming molds are customizable to print logos and flavor markings to enhance brand recognition. The entire production line requires a minimum of two operators, thus significantly reducing overall production costs. During peak seasons, an additional modularized filling system makes switching fillings quick and easy and increases production efficiency. The filling machine can process and retain large pieces of ingredients like corn kernels, diced carrots, and peas intact without over-compression. ANKO can also customize the entire production line to meet specific requirements to create a fully automated specialized Empanada production line.

- Country

United States

United States Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in the United States with advanced automated food production technology for making Dumplings, Egg Rolls, Empanadas, Spring Rolls, Burritos, Mochi, Quesadillas, and Spring Roll Wrappers. We also offer integrated solutions for popular foods such as Samosas, Momo, Pierogi, Tortillas, Shumai, Tapioca Pearls, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.To provide timely and localized service, ANKO has established a branch office in the United States. With a dedicated team based locally, we’re able to offer in-person consultation, machine demonstrations, and responsive after-sales support tailored to the specific needs of our American clients.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

"Empanada" is a pastry filled with various ingredients; the name comes from the Spanish verb empanar, meaning "to wrap" or "to coat." In Polish, a similar pastry is known as Pastel. Empanadas originated in Spain, but they became extremely popular all over Latin America. They are generally made into half-moon shapes and can also be made into triangular or rectangular shapes. Every country has its unique preparation and way of enjoying an Empanada; the fillings are often made with available ingredients found in most households. Popular fillings include beef, chicken, and cheese, while seafood is commonly used in coastal areas. Both wheat flour and cornstarch are used for the dough. Empanadas can be either baked or fried. In Argentina, Empanadas are made with a crisp and flakier crust, while the Chileans prefer their Empanadas a little more soft and hearty. According to the Argentine Pizza and Empanada Association (APYCE - Asociación de Pizzerías y Casas de Empanadas de la República Argentina), Empanadas rank third in the country's local food consumption because of their affordability and taste. Empanadas are sold by street vendors, in restaurants, supermarkets, and wholesale. Empanadas are more than a pastry; they are considered a cultural symbol and a staple in Latin America. They are essential at birthday parties, family gatherings, weddings, and other celebrations. April 8th is commonly celebrated annually as National Empanada Day, a testament to the deep-rooted cultural significance of this pastry. Many festivities and special promotions are held annually to attract more consumers to enjoy Empanadas.

With the rapid rise of Latin American cuisine in the U.S., Empanadas – from freshly baked varieties at food trucks to frozen versions in big-box stores – have become a popular favorite among Americans. In addition to classic flavors, producers have developed new options like American BBQ, Spanish chorizo, chocolate, and dulce de leche, allowing Empanadas to suit local tastes. New flavors such as spinach and cheese, Italian Caprese, creamy corn, and spicy potato are also available as an option for vegetarians, often utilizing fresh vegetables and whole grains. These innovative flavors have resonated with vegetarians and even attracted non-vegetarians, making Empanadas a beloved Latin American food, a new favorite in the U.S. marketplace.- Handmade Recipe

-

Food Ingredient

Wrapper: All-purpose flour/Salt/Unsalted butter/Eggs/Oil/Warm water, Filling: White onions/Garlic/Red bell peppers/Chili powder/Cumin powder/Sweet paprika/Oregano/Beef chunks/Ground beef/Black pepper/Spring onions/Green olives/Parsley/Hard boiled eggs

Empanada Dough

(1) Mix flour and salt in a bowl, then incorporate eggs and butter. (2) Add oil and warm water to the flour mixture and knead to form a dough. (3) Place the dough into a lightly oiled container to rest for an hour.

Filling

(1) Chop onions, garlic, red bell peppers, spring onions, green olives, and parsley into small dice; cut the hard-boiled eggs into small pieces (2) In a heated pan, add cooking oil and onions to cook and sweat for 10 minutes, then add garlic and red bell peppers to the onions and cook for another 10 minutes. (3) Season the vegetables with chili powder, cumin, sweet paprika, and oregano. (4) Add ground beef to the pan to brown, then season it with salt and pepper. Then add beef chunks to the mixture and cook for anther 10 minutes. (5) Remove the meat filling and place it into a bowl, then add chopped spring onions, green olives, parsley, and chopped eggs. Mix well and then refrigerate for at least one hour.

Product assembly

(1) Roll the dough flat to a desired thickness. Use a round pastry cutter to carve out round Empanada wrappers. (2) Remove the filling from the refrigerator, and place two tablespoons full of filling onto the center of the pastry wrapper. (3) Use a little water to wet the edge of the wrapper, then fold it in half to create a crescent shape. Pinch the edges to seal the pastry, and press along the edges using a fork. (4) Deep fry the Empanadas until golden brown, remove from oil and serve.

- Downloads

English

English