Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

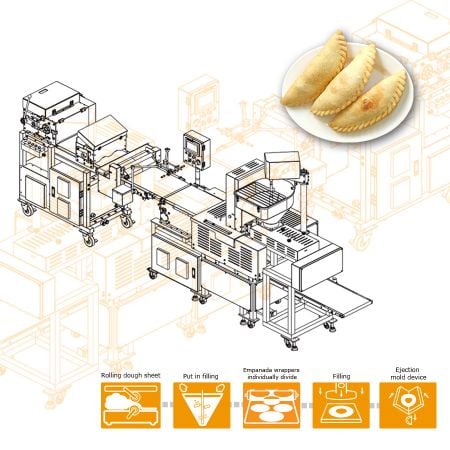

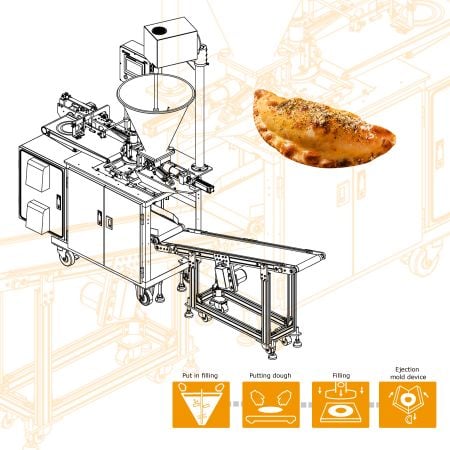

ANKO developed the high-capacity EMP-3000 Empanada Making Machine based on a client’s requirements in the United States. Our team conducted an in-depth analysis of operations at the client’s facility to understand the challenges of their Empanada production. This client needed a machine that could “quickly adapt to market demands while maintaining a high-quality product output.” After multiple test runs and refinement, the ANKO EMP-3000 Empanada Making Machine was launched. This model has a capacity of producing 3,000 Empanadas per hour to help clients’ productivity while saving on labor costs. The easy-to-remove filling system enables continuous production and improves quality control, providing a competitive advantage in food manufacturing.

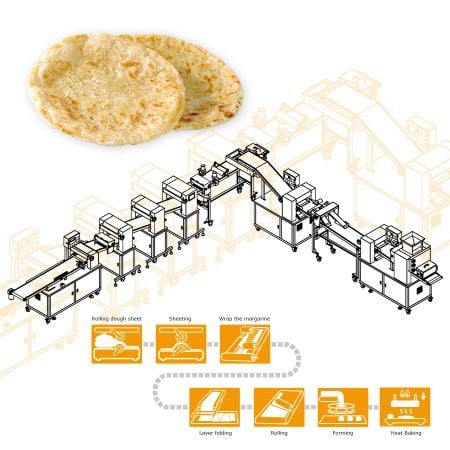

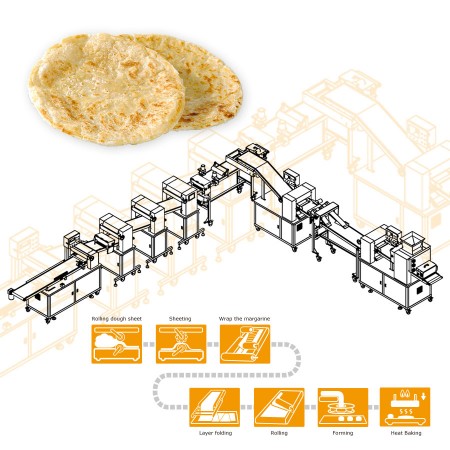

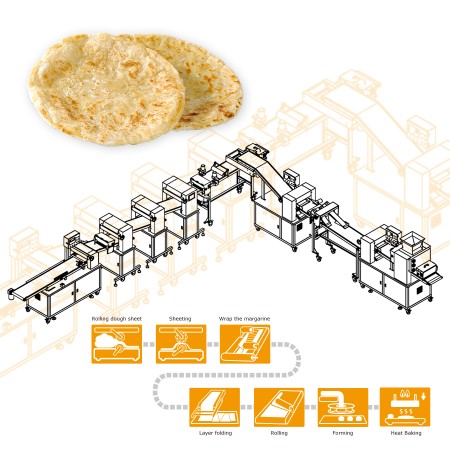

This ANKO client is a well-known food manufacturer in Bangladesh, and their business scope includes multiple food fields. They have been using semi-automatic equipment to produce Paratha to supply their domestic market demand. To expand their Paratha sales internationally, this client purchased ANKO’s fully automated food machines to produce an estimated 100,000 pieces per day in order to meet the global market demand. This ANKO return customer is confident in our high-quality machine performance and the professional support services we provide. Our team customized a Triple Line High Capacity Paratha Production Line for this company. With the assistance of ANKO’s Bangladeshi local distributors, this client visited our Taiwan headquarters to conduct trial machine operations, and the results successfully met the client’s required production requirements and food specifications.

ANKO has found there is an increasing demand for Empanadas in the World marketplace. ANKO’s research has determined that this phenomenon not only exists in Spain and Latin American countries, but also in the USA, Canada, Australia, and the Philippines. And as a result, there is a great demand for automated Empanada machines. ANKO has been approached by many companies and different clients seeking a machine that can process high fat content dough such as puff pastry in order to make Empanadas. Currently, ANKO’s HLT-700 Multipurpose Filling and Forming Machine can produce Spanish style Empanadas with the capacity of over a thousand pieces of products per hour using a variety of forming molds. ANKO’s new EMP-900 Empanada Making Machine is our latest design for making Empanadas with high fat content pastry dough. ANKO’s team has devoted much time researching and developing our Semi-automated Clamping Mold Device, and it was tested using ANKO’s client’s recipe from the USA. This machine has successfully produced Empanadas that can be either baked or deep-fried and fulfilled ANKO’s client product specifications.

The client supplies Danish pastries, chapatis, Mille-feuilles and cinnamon rolls, and they wished to upgrade their production capacity in order to increase the sales in fast-food chains.

This company is a food supplier that specialized in providing frozen prepared foods in India. They contacted ANKO for food processing equipment solutions due to increasing demands. The quality, weight, and size of the handmade paratha aren't consistent and the production capacity is low. It would therefore be a total solution if paratha production equipment can solve all problems.

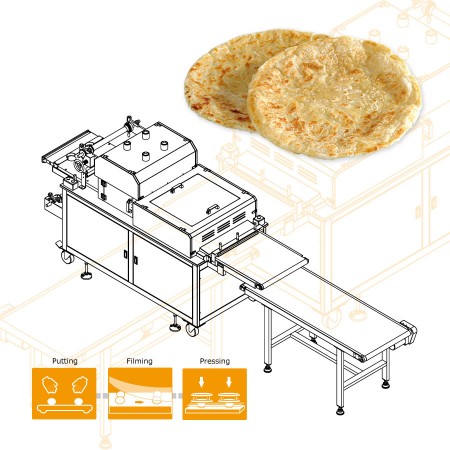

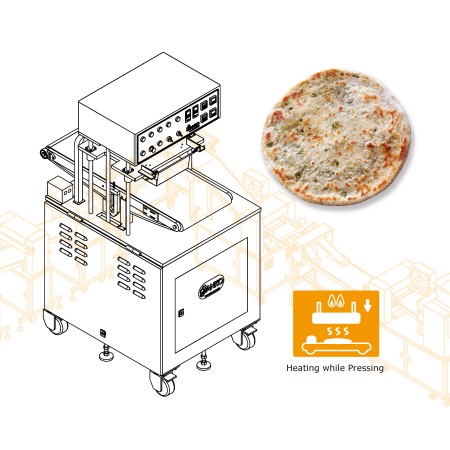

Muslim is the major population in Middle East, which shapes their food culture, halal food. Also, in a fast-paced environment, frozen food becomes one of favorite items in shopping lists. The client is also running business about frozen food like kubba, samosa, chicken fingers. When every producer is keen to develop product differentiation in size or new product, they need a machine supplier who can shortly customize machine to meet individual requirement. ANKO is a professional team; more than half of employees are experienced engineers in which there are over 20 RD engineers. Through interior integration, we quickly react to modify machine as required. Therefore, the client asked ANKO to customize large size filming and pressing machine for him.

The client had been processing aquatic food products on the beginning of his business and becoming a leader in local food industry. Then, the client established a new plant to produce flour and pastries. Bangladesh is a dense area in which there are tremendous opportunities in the frozen food market. Because paratha is a common food in this area and the client has a flour factory, he decided to run a paratha production line. By word of mouth, they approved ANKO's ability to plan a turnkey. Plus, our advantage is the flexibility of planning production line and installing machine, depending on the client's space. Therefore, they believe in our machines and services, purchasing the whole production line from dough mixer to food packaging from ANKO.

The client's company had gained a firm foothold in India and then he planned to expand into the U.S. market so that having accurate food quality control and standardization, product line extension, productivity improvement are essential. He compared ANKO with other food machine suppliers and found ANKO is superior to them. ANKO has higher market share in India, offers wrapper and filling recipe to meet individual need, and has years' experience in designing food production routes and supply chain integration. Finally, he chose ANKO as their business partner.