ANKO Automatic Spring Roll Wrapper Making Machine Fulfills an Indian Client’s Various Product Requirements

This client operates a bakery business in the Middle East and many other countries in Asia. Their proprietary brand boasts a complete production supply chain, encompassing farms that supply raw materials, factories for processing, baking, and manufacturing, as well as several bakeries, distributors wholesale and retails. As their business expanded, this client actively sought food machinery manufacturers that could provide high quality machines and professional services. They recognized ANKO’s excellent reputation in the industry and acknowledged ANKO's highly efficient and fully automatic Spring Roll wrapper machine. The machine can produce a wide range of products including Samosa wrappers, and Crepes. This diverse product line can reduce production costs significantly, hence, this client chooses ANKO to help them integrate a fully automatic production process to rigorously uphold food hygiene, safety, and quality standards. This collaboration ensured the ability to provide more high-quality and delicious food products to more consumers.

Spring Roll Wrapper

ANKO Team Research Problem Solving or Solution Delivery

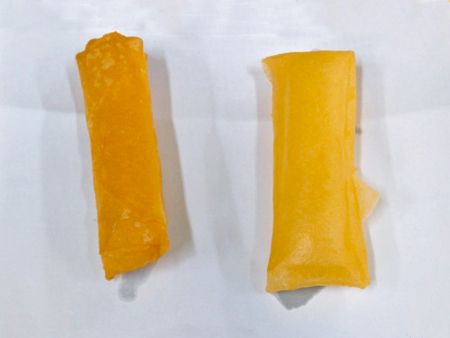

Solution 1. How to adjust Spring Roll Wrappers’ elasticity and adhesiveness?

This client wants to make Spring Roll Wrappers with a soft, delicate texture and good elasticity which can be easily separated from the pile to easily use for making other products. When testing the client’s original Spring Roll Wrapper recipe, ANKO’s team observed the lack of elasticity in the wrappers, so we suggested a lower batter storing temperature, and a lower batter baking temperature to increase the wrappers’ elasticity. We also examined the prints on the Spring Roll Wrappers to determine the heating conditions, and then finetuned the heating drums and parameter settings. Based on ANKO’s experience, we were able to create the Spring Roll Wrappers our client desired. Finally, the client was able to produce Spring Roll Wrappers with optimal elasticity and adhesiveness, which facilitated the following production processes.

Solution 2. How to Make Crispier Spring Rolls?

This ANKO client has an extensive product line, and one of the crispy baked goods is made with Spring Roll Wrappers. Therefore, ANKO’s professional recipe researcher was involved with developing a crisper wrapper. This ensured the final products achieve the quality, appearance, and texture our client desired...(Contact ANKO for more information)

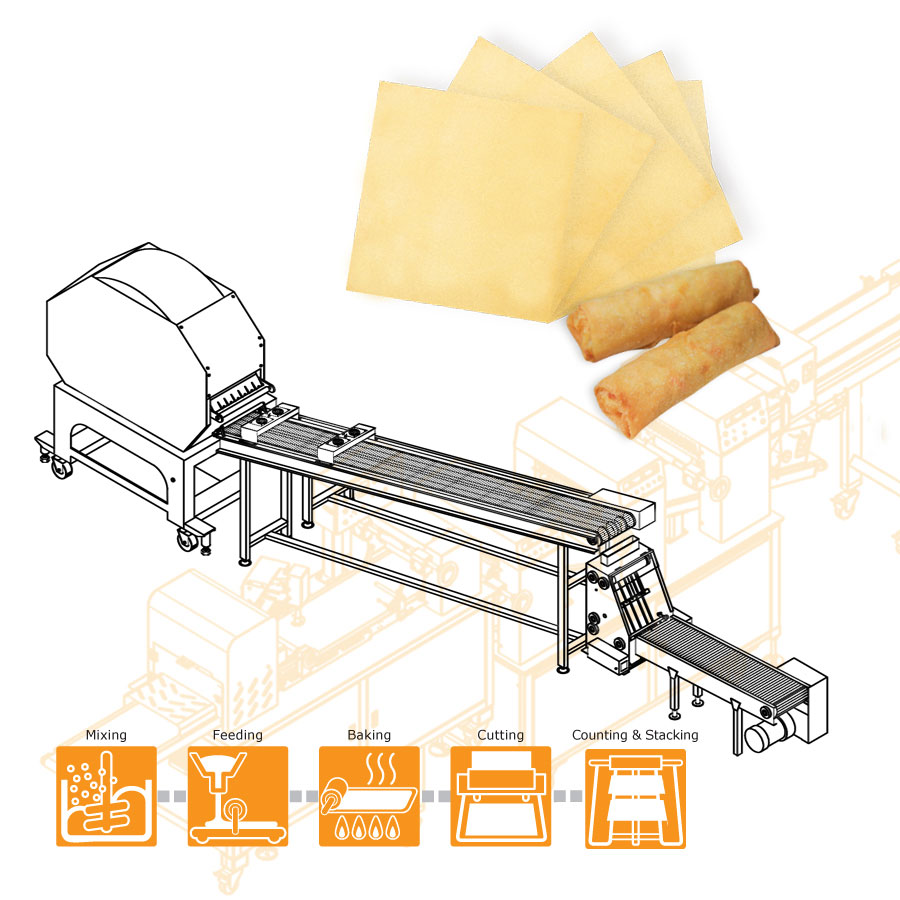

Food Equipment Introduction

- Mix the batter thoroughly and then transfer it into the batter hopper

- Adjust the baking temperature and baking drum status on the control penal

- Spread the batter onto the baking drum

- Use the fan to cool down the baked wrappers

- Cut wrappers into desired sizes

- Automatically stack the wrappers into a pile

Fundamental of Design

- This client has been producing Spring Roll Wrappers manually and sought to increase their production capacity by transitioning to automated manufacturing. Therefore, ANKO recommended our SRP Automatic Spring Roll Wrapper Machine, which operates with great consistency and has the high output of 2,700 sheets per hour. An additional production line can be applied for a dual production line when the client’s product demand increases.

- The size and dimension of the Spring Roll Wrappers can be adjusted via parameter settings; standardized machine production prevents inconsistencies that may occur in manual productions.

- An automated stacking mechanism piles individual wrappers into sets of 15 to 30 pieces, and then they are transported to the packaging area on a conveyor belt. This ensures faster and more accurate production than a manual process.

- When transitioning from handmade to automated food production, ANKO’s team understands that clients may have concerns about product taste and textures due to mechanical processing. ANKO’s innovative wrapper making mechanism simulates handmade procedures to create Spring Roll Wrappers that look and taste like handmade.

- In addition to Spring Roll Wrappers, the SRP Automatic Spring Roll Wrapper machine can produce a variety of other products, such as Samosa wrappers, Crepes, and Egg sheets, thus creating new business opportunities for our clients.

- Solution Proposal

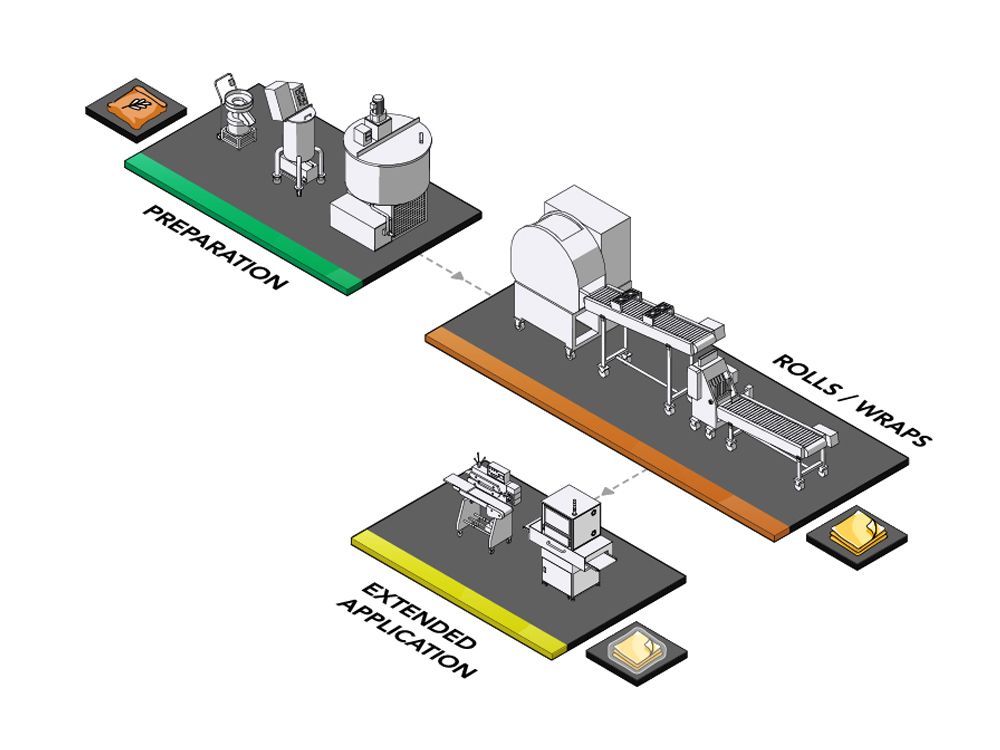

ANKO’s SRP Automatic Spring Roll Wrapper Machine Creates Customizable and Integrated Production Solutions

ANKO did

To create a complete Spring Roll Wrapper production line, a batter mixer and storage tank are indispensable. The batter mixer is highly efficient, and the batter storage tank enhances the overall product flavor and texture during overnight storage time. Once the wrappers are made with ANKO’s Spring Roll Wrapper Machine, they are automatically stacked by the machine and fed into the packaging machine for sealing and bagging. Adding X-Ray inspection equipment can increase food safety and quality control standards. ANKO can configurate and plan an integrated production solution for you.

ANKO can help you more

Additionally, ANKO’s innovative "Food Lab" can collaborate with you in developing new products. With our professional manufacturing technology and commitment to ethnic food recipe research, we have successfully handled tens of thousands of cases.

Please click to Learn More or complete the inquiry form below to receive more information. Our professional consultants will be glad to assist you.

- Machines

-

SRP Series

ANKO's R&D team designed a baking drum that bakes the batter at high temperatures, cools the wrappers with a fan, and then uses a cutter mechanism to divide Spring Roll Wrappers automatically. If the size of the wrappers needs to be adjusted, replace the relevant components, and set the parameters. After that, final products with a thickness of 0.4 to 0.8 mm can be made. There are three different SRP automatic Spring Roll Wrapper-making machines. The wrapper width can be changed from 220 mm to 420 mm according to the client’s product specifications. The production capacity is 2,700 pieces per hour. With our duo production line capacity can reach as high as 5,400 pieces per hour while maintaining high quality products. ANKO offers improved production efficiency, reducing labor costs, and high-quality products.

SR-27

The SR-27 Automatic Spring Roll Production Line takes only 1.4 seconds to produce a high-quality Spring Roll and, it requires minimum employees to operate. It is the most efficient machine for large food factories, central kitchens, and high-volume manufacturers. This machine has a 50 Liter filling hopper and a unique filling system that can process a variety of ingredients, such as pure vegetables, ground meats, bean sprouts and firm tofu, crab meat and cheese, and potato fillings, while keeping the original texture of different ingredients without over processing. Moreover, the new user-friendly touch screen control panel can be upgraded with an IoT system. This fully automated machine can produce Spring Rolls with measurements of 100mm in length, 25-32mm in radius, a product weight from 40-50g per piece, and the wrapper thickness can be regulated between 0.4-0.5 mm. We can also create customized Spring Roll products upon request. If you are interested in our SR-27 machine, please complete the form below.

- Video

- Country

India

India Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in India with advanced automated food production technology for making Layered and Stuffed Paratha, Spring Roll Wrapper, Samosa Pastry, and Rasgulla. We also offer integrated solutions for popular foods such as Samosa, Momo, Dumplings, Chapati, Kachori, Pani Puri, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Spring Rolls are a traditional Chinese food, usually served as a snack or a savory dish. Over time, Spring Rolls were brought to different countries, and they vary due to unique local cultural influences, interesting new ingredients and cooking techniques, and have been influenced from flavors around the world. In the United States, Spring Rolls have evolved into Egg Rolls, which are made into bigger pieces, usually sold at 3 ounces (about 85 grams) or larger and made with thicker wrappers as compared to the traditional Chinese Spring Rolls. In the Philippines, Spring Rolls are known as Lumpia, typically made into thin long Rolls, and served as a street food snack. Vietnamese Spring Rolls are wrapped in rice papers and contain pork, shrimp, and vegetables, offering a refreshing texture. In the Netherlands, Spring Rolls are called Loempia, and are usually filled with bean sprouts. Deep-frying is the most common way of cooking Spring Rolls, which creates an irresistibly golden and crispy texture. However, with increasing consumer health consciousness, baked Spring Rolls that are lower in fat have gained popularity in recent years. Spring Rolls can also be made into desserts by substituting savory fillings with various sweet ingredients. Chocolate banana is one of the most popular sweet Spring Rolls, and other options include apple, cream cheese, or assorted fruits.

- Handmade Recipe

-

Food Ingredient

Salt/Flour/Water

How to make

(1) Place flour and salt together in a mixing bowl, then add water (2) Mix well and then sift the batter to remove any lumps (3) Pour flour batter on an oiled hot pan and spread the batter out thinly (4) The Wrapper is ready when the edges begin to curl

- Downloads

English

English