Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

ANKO provides our clients in India with advanced automated food production technology for making Layered and Stuffed Paratha, Spring Roll Wrapper, Samosa Pastry, and Rasgulla. We also offer integrated solutions for popular foods such as Samosa, Momo, Dumplings, Chapati, Kachori, Pani Puri, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.

Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.

Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

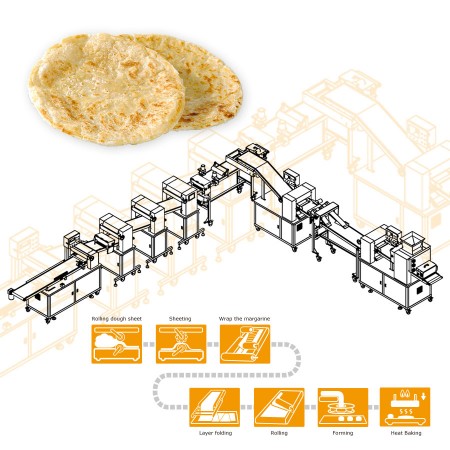

The client supplies Danish pastries, chapatis, Mille-feuilles and cinnamon rolls, and they wished to upgrade their production capacity in order to increase the sales in fast-food chains.

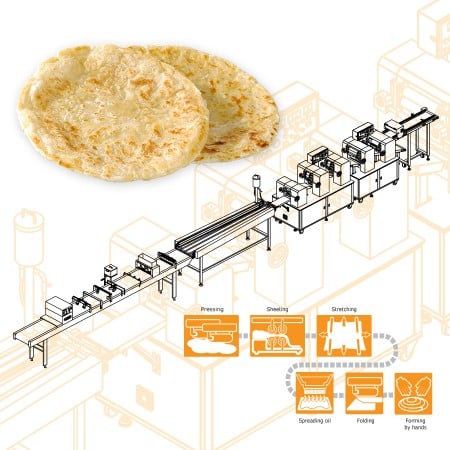

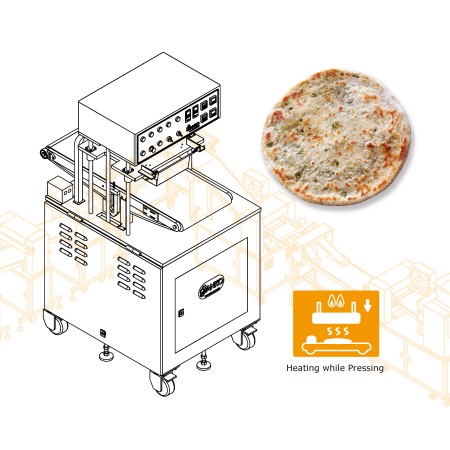

This company is a food supplier that specialized in providing frozen prepared foods in India. They contacted ANKO for food processing equipment solutions due to increasing demands. The quality, weight, and size of the handmade paratha aren't consistent and the production capacity is low. It would therefore be a total solution if paratha production equipment can solve all problems.

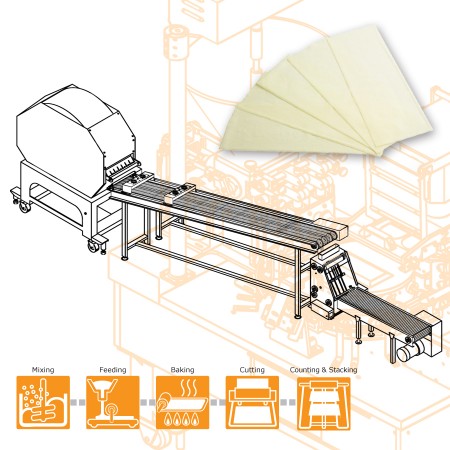

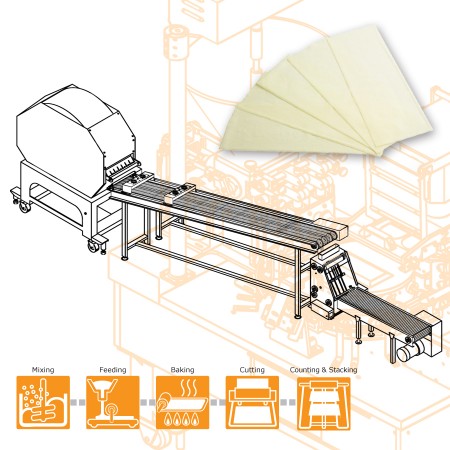

This client operates a bakery business in the Middle East and many other countries in Asia. Their proprietary brand boasts a complete production supply chain, encompassing farms that supply raw materials, factories for processing, baking, and manufacturing, as well as several bakeries, distributors wholesale and retails. As their business expanded, this client actively sought food machinery manufacturers that could provide high quality machines and professional services. They recognized ANKO’s excellent reputation in the industry and acknowledged ANKO's highly efficient and fully automatic Spring Roll wrapper machine. The machine can produce a wide range of products including Samosa wrappers, and Crepes. This diverse product line can reduce production costs significantly, hence, this client chooses ANKO to help them integrate a fully automatic production process to rigorously uphold food hygiene, safety, and quality standards. This collaboration ensured the ability to provide more high-quality and delicious food products to more consumers.

This ANKO client is a well-known food producer and supplier in India, their frozen food and baked goods are widely distributed throughout the country. Samosa is a popular staple; it can be served as street food snacks, and they are also a key part of festive celebrations. Islam is the second largest religion in India, and Samosas are always in high demand during Ramadan. Therefore, this client was in need of professional commercial food machines that can produce high quality products in large quantities to meet the market demand. The machines they found locally could not meet their product requirements, so they contacted ANKO. Subsequently they visited ANKO’s headquarters in Taiwan. After testing ANKO’s machine with production trials, our professional teams provided many production solutions, and the client was very satisfied with our Samosa Pastry Sheet Machines.

The client is a frozen food manufacturer, producing Indian food and selling to grocery stores and supermarkets. The growth of demand for paratha urges the client to seek automatic production line so as to reduce labor cost and increase productivity. The texture and taste of lachha paratha is layered and crispy that ANKO R&D team understands and keeps the characters in machine-made products. Our machine is capable of stretching dough to be pervious to light as well as producing products up to 2,000 pieces in one hour. The client satisfied those advantages of the machine so that they decided to cooperate with ANKO. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

The client runs a bakery group whose divisions are present in many countries of the Middle East and Asia. They form a complete supply chain, including farms for providing raw materials, industrial bakeries for processing food, and numerous retail bakeries and agents. They implement quality control strictly to ensure that products remain their best quality as delivering to consumers anytime. With the business expansion, the client was proactive to find a food machine supplier who delivers not only good quality machine, but also professional after sales services. In 2000, they received information about ANKO's spring roll machine which can produce good quality samosa pastry as well. Such a multipurpose and cost-saving machine was the reason that they decided to cooperate with ANKO. After using ANKO machine for 10 years, due to the stability of the machine, we won their trust. They have ANKO in mind and believe we could help them further expand other new product lines.

The client's company had gained a firm foothold in India and then he planned to expand into the U.S. market so that having accurate food quality control and standardization, product line extension, productivity improvement are essential. He compared ANKO with other food machine suppliers and found ANKO is superior to them. ANKO has higher market share in India, offers wrapper and filling recipe to meet individual need, and has years' experience in designing food production routes and supply chain integration. Finally, he chose ANKO as their business partner.

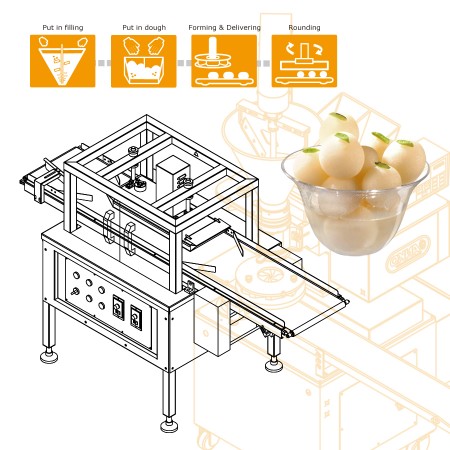

The confectionery factory has established nearly 100 years. They expand their Indian sweets and snacks market along the Indian migration route across the globe. In 2009, in order to increase production capacity and save labor costs, the client contacted ANKO and inquired about the rasgulla automatic production line, which combines SD-97W Automatic Encrusting and Forming Machine with RC-180 Automatic Rounding Machine. In the process of trying out the SD-97W, we adjusted the extruding pressure to maintain the texture of rasgulla. The client was satisfied with the final products and full of confidence in the investment, so he placed an order for three production lines. "Is ANKO trustworthy?" the answer is obvious.