Automatic Samosa Pastry Machine to Achieve Business Growth for an Indian Company

The client runs a bakery group whose divisions are present in many countries of the Middle East and Asia. They form a complete supply chain, including farms for providing raw materials, industrial bakeries for processing food, and numerous retail bakeries and agents. They implement quality control strictly to ensure that products remain their best quality as delivering to consumers anytime. With the business expansion, the client was proactive to find a food machine supplier who delivers not only good quality machine, but also professional after sales services. In 2000, they received information about ANKO's spring roll machine which can produce good quality samosa pastry as well. Such a multipurpose and cost-saving machine was the reason that they decided to cooperate with ANKO. After using ANKO machine for 10 years, due to the stability of the machine, we won their trust. They have ANKO in mind and believe we could help them further expand other new product lines.

Samosa Pastry

ANKO Team Research Problem Solving or Solution Delivery

How to improve the color and texture of samosa pastry?

There were bubbles on samosa pastry during machine test. After careful inspection, we found small oil lumps and residues on the surface of baking drum. The solution was to...(Please contact us to get more information)

How to solve the problem that the baked samosa pastry could not be peeled off the baking drum?

In the production process, the problem led to the unsmooth delivery between the baking drum to the cooling conveyor. Our engineer detected the edge of scraper was not level enough to scrape pastry from the baking drum. Finally, we eliminated the problem by polishing the scraper.

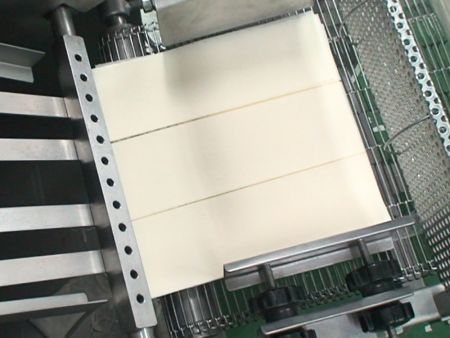

The pastry belt could not be cut into pieces, how did we cope with the problem?

In this case, a belt of samosa pastry could not be easily cut into pieces, which affected the smoothness of production process. After checking the device, we found the cutter was positioned incorrectly. Gradually, there was a groove on the opposite wheel, as a result, the problem mentioned at the beginning emerged. Our engineer adjusted the position of cutter and wheel to make the production process smooth.

Food Equipment Introduction

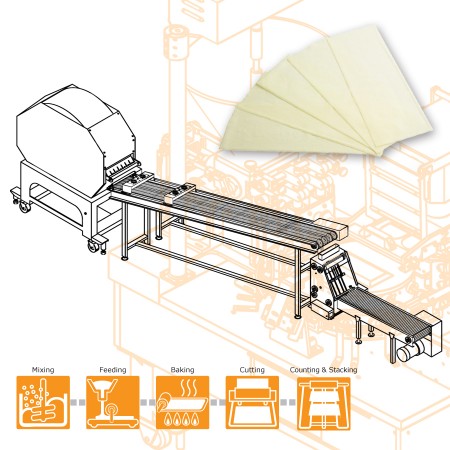

- Pour well-stirred batter into the hopper.

- Adjust settings on the control panel and make sure the temperature and condition of baking drum.

- Bake batter into a belt of pastry.

- Divide the pastry belt into 3 strips.

- Cool them by fans.

- Cut into proper length.

- Stack pastries.

Fundamental of Design

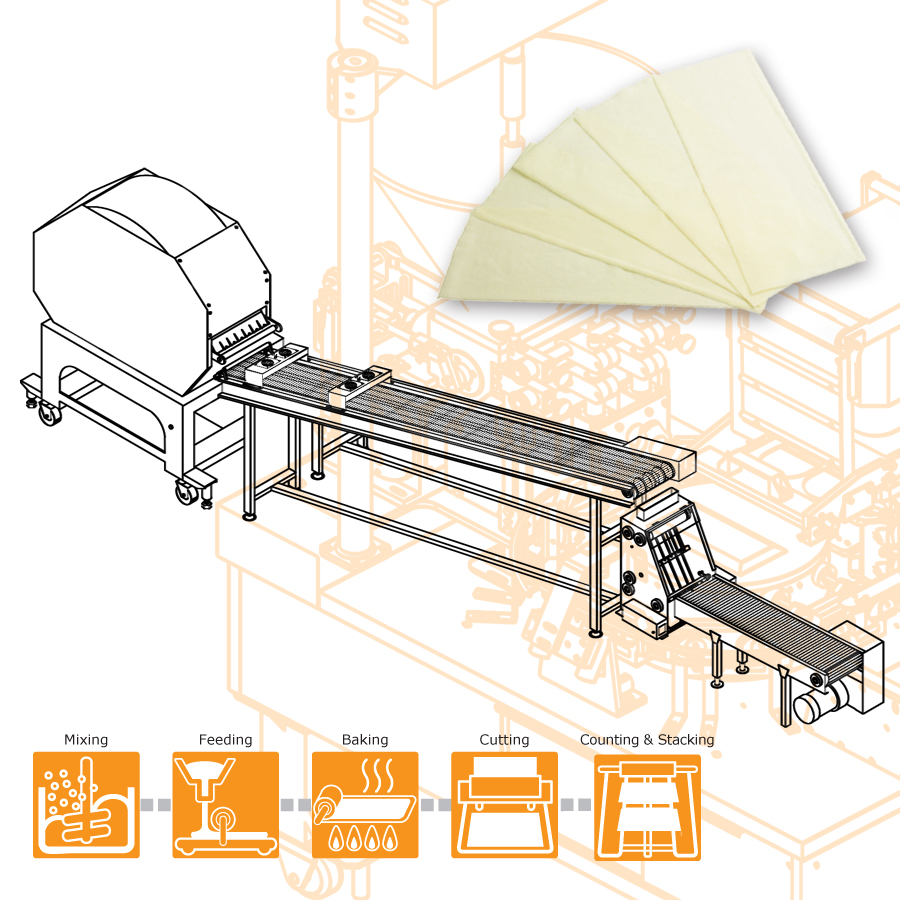

- To meet the client's requirement of increasing samosa product yield, ANKO designed the stable samosa pastry machine that hourly produces 8,100 pieces.

- The length and width of samosa pastry are adjustable through the easy changes of parts and data setting. Machine-made products with uniform size may solve the problem of unstable quality caused by hand-made production processes.

- The automatic stacking device piles pastries neatly. Before that, a cooling conveyor is installed to quickly cool down pastry. These innovative designs aim to stabilize and uniform pastry quality.

- Product quality is of concern to the client and ANKO. We are devoted to provide consumers the safest food with best quality. Designing SRP machine, we took the client's requirements into consideration. We designed stable SRP machine for client to produce samosa pastry with taste and texture like handmade, in addition, uniform size.

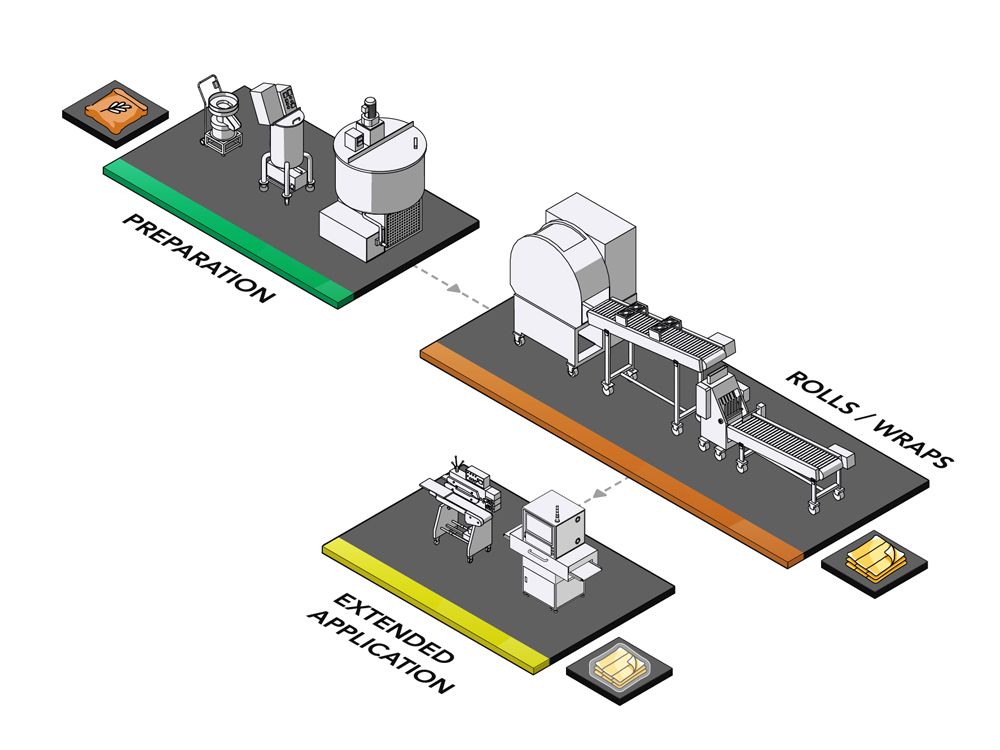

Processing Line Planning

- Sieving

- Mixing

- Spring Roll Equipment

- Sealing

- Solution Proposal

Samosa Pastry Production Solution to Increase Manufacturing Capacity

ANKO did

Being a pioneer in the automated food machine industry, ANKO’s SRP Automatic Spring Roll and Samosa Pastry Sheet Machine is capable of producing 8,100 pieces of Samosa Pastries in one hour. For high volume producers, we also can offer the SRP-90 Double Line solution to increase the production volume of up to 16,200 pcs/hour.

ANKO can help you more

In order to increase the automation levels, ANKO offers the front-end and back-end equipment, such as Batter Mixer, Batter Storing, Cooling and Resting Tank, Packaging Machine and Food X-ray Inspection Machine to assemble a highly efficient production line for fulfilling the large orders.

According to your requirement, we will recommend a solution that is suitable for you. For more information, please click Learn More or fill out the inquiry form below.

- Machines

-

SRP Automatic Spring Roll And Samosa Pastry Sheet Machine

After the batter is poured into the hopper, the batter is baked at high temperature on the baking drum designed by ANKO RD team, and then cooled by fans immediately. Subsequently the cutter automatically cuts the pastry belt into proper size as required. The easy changes of parts or data settings are very convenient for users to adjust the pastry width. With the copper-made rotary cutter, the machine can efficiently produce 8,100 pieces in one hour. Providing stable and high quality products also solves the labor shortage, bring big profit to the client.

SRP Automatic Crepe Machine

The purpose of building SRP Automatic Crepe Machine is to keep pace with the diversified food market. Through the adjustment of parts and data setting, the machine can produce pastries of spring roll, but also samosa, blini, blintzes, nalesniki, and crepe with stable and high quality.

- Video

- Photo Gallery

- Country

India

India Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in India with advanced automated food production technology for making Layered and Stuffed Paratha, Spring Roll Wrapper, Samosa Pastry, and Rasgulla. We also offer integrated solutions for popular foods such as Samosa, Momo, Dumplings, Chapati, Kachori, Pani Puri, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Like dumpling, samosa is made with a dough wrapper stuffed with savory stuffing and then deep fried. Stuffing is usually the mixture of mashed potato, peas, onions and minced meat. Some people also add pine nuts. Originated from the Middle East, samosa then has been spread to India and other Southeast Asia. With different culture and environment, the dish infuses local ingredients. The popular samosa can be seen everywhere in India, either as an appetizer or snack. Mostly, people enjoy it with mint sauce (raita) or chutney.

- Handmade Recipe

-

Food Ingredient

Maida/Ghee/Ajwain/Salt/Water

How to make

(1) Mix maida, ajwain, salt in a bowl. (2) Add ghee and a little water until the mixture become crumbly. (3) Add water while kneading the mixture to make it pliable. (4) Divide dough into equal size dough balls. (5) Apply a rolling pin to roll out each of them into 0.5 mm thin round pastry. (6) Cut in half, ready to fill up with filling.

- Downloads

English

English