Indian Customer's Increased Paratha Demand Was Fulfilled By Utilizing ANKO's Lachha Paratha Production Line

The client is a frozen food manufacturer, producing Indian food and selling to grocery stores and supermarkets. The growth of demand for paratha urges the client to seek automatic production line so as to reduce labor cost and increase productivity. The texture and taste of lachha paratha is layered and crispy that ANKO R&D team understands and keeps the characters in machine-made products. Our machine is capable of stretching dough to be pervious to light as well as producing products up to 2,000 pieces in one hour. The client satisfied those advantages of the machine so that they decided to cooperate with ANKO. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

Lachha Paratha

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. How to prevent lachha paratha from peeling off in the production process.

"The less quantity of salt causes the low elasticity of lachha paratha dough", ANKO engineer found through a repetitive observation of their recipe and production process. To solve the problem, ......(Please contact us to get more information)

Solution 2. The difficulty of rolling up dough wrapper resulted in its accumulation.

In the process of machine test, ANKO engineers found that the dough character changed by local climate could not be formed well by the original machine design, as a result, dough was accumulated. The first step of the solution is to move the former rolling unit outwards. The width of the rolled part reduced from......(Please contact us to get more information)

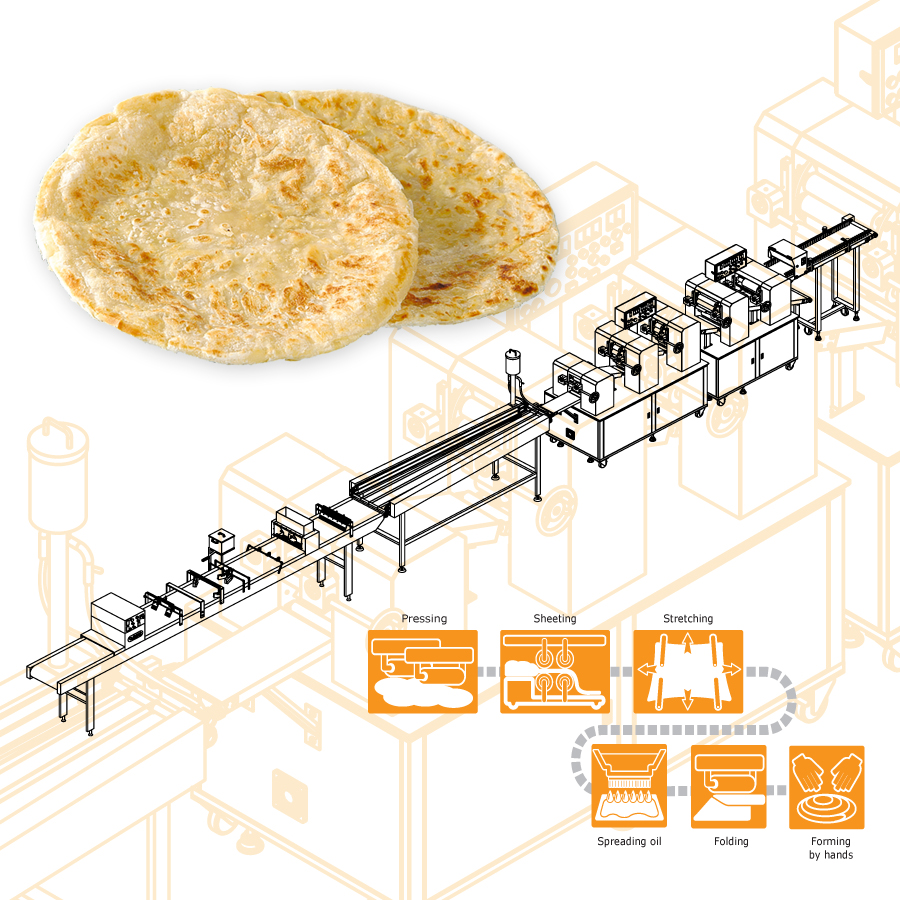

Food Equipment Introduction

- Put prepared dough into dough hopper.

- Press dough into dough belt.

- Sheet dough belt into desired thickness.

- Stretch dough belt toward the right side and left side.

- Drop oil.

- Longitudinal cut dough belt into two strips.

- Drop oil.

- Cut into required length.

- Roll up.

How to make multilayered lachha paratha by machine?

The percentage of water and oil is relatively high in dough for lachha paratha. Oil is the main ingredient that creates crispy and layered taste. LAP-2200 evenly drops oil on dough after the processes of stretching and after folding, respectively. The ingenuity of machine design makes dough full of oil. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

How does machine stretch dough to be thin, nearly pervious to light?

In order to keep gluten and stretchability of dough for lachha paratha, water and oil are usually added much more. Although pressing or sheeting is a way to make dough thinner, the gluten is weakened and not stretchy. LAP-2200 sheeting roller units press dough again and again until it becomes nearly 3mm thin dough belt. Then, the dough belt will be delivered to the stretching device, which clips dough by four belts. Dough will be slowly stretched along the track, becoming three times the width and around 1mm thick that is almost pervious to light. The stretching device is not as simple as people think. During the process of stretching, how to prevent dough being tore off or falling off is related to the way we assemble belts and rollers. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

- Solution Proposal

ANKO's Lachha Paratha Production Solution: Transition Your Manufacturing Process to Automation

ANKO did

Leveraging ANKO's extensive experience, we've desined a Lachha Paratha Production Line, seamlessly managing dough belt production to the final product, achieving a capacity of 2,100 to 6,300 pieces per hour. Ideal for medium to large-scale Lachha Paratha manufacturers, this solution resolves production challenges and tailors to specific client demands for flawless Lachha Paratha output.

ANKO can help you more

ANKO offers a comprehensive Lachha Paratha Production Solution encompassing dough mixers, Lachha Paratha production lines, and packaging and food x-ray inspection machines. Our services go beyond equipment planning; we provide recipe consultations, ensuring your Lachha Paratha meets your preferred tastes, textures, and appearances. Click Learn More for detailed service information.

To provide local and immediate support, our agents in the Middle East and South Asia offer region-specific recipes, considering local material characteristics and environmental factors to develop the most suitable Lachha Paratha products for your business. For further details, please submit an inquiry below.

- Machines

-

LAP-2200 (Current Model: LAP-5000)

How to keep gluten, stretchability, and layers during the machine-made processes? When ANKO's team designed LAP-2200, we considered the complicated recipe in detail and paratha characters. For example, the Lachha Paratha and Green Scallion Pie Production Line is capable of evenly stretching dough into extremely thin, almost transparent. Then, as you see handmade food recipe, spreading oil is inevitable between some steps, so LAP-2200 equips with oil dropping device. Moreover, when producing paratha layers, the design of folding and rolling devices has to think of the oily and thin characters of paratha. ANKO manufactures fully automatic machine to simplify complicated making procedures, which not only saves time and labor cost, but also increases productivity. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

- Video

ANKO Lachha Paratha & Green Scallion Pie Production Line – The video shows a complete production line from feeding, pressing, sheeting, stretching, dropping, longitudinal cutting, folding, cutting, rolling to forming. Please refer to the video. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

- Country

India

India Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in India with advanced automated food production technology for making Layered and Stuffed Paratha, Spring Roll Wrapper, Samosa Pastry, and Rasgulla. We also offer integrated solutions for popular foods such as Samosa, Momo, Dumplings, Chapati, Kachori, Pani Puri, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Lachha Paratha is quintessential food of Indian daily cuisine. The unleavened bread is served almost every meal in a day if you live in India. The cook adds oil in dough, and then rounds it, rolls out it, thins it, pleats it, swirls it, and presses it to form the final product. When Lachha Paratha is sizzling on a heated pan, no one can resist the delicious aroma.

- Handmade Recipe

-

Food Ingredient

Water/All Purpose Flour/Oil or Ghee/Salt

How to make

(1) Mix flour, salt, oil, and some water in a bowl. Add more water if needed. (2) Knead the dough until it becomes elastic. (3) Dust a pinch of flour and apply a pin to roll the dough into a circle as thin as possible. (4) Spread ghee or oil with your fingers or brush. (5) Sprinkle flour on the surface of dough and start pleating into a pleated strip. (6) Spiral the pleated strip into a circle. (7) Sprinkle flour on the surface and carefully roll it into a flat circle. (8) Heat a tava and cook one side of paratha. (9) Apply a spatula to flip it over. (10) Spread some oil on top and flip it over. (11) Repeat the last step until both sides are golden brown.

- Downloads

English

English