Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

ANKO's food machines are suitable for restaurant, central kitchen, cloud kitchen, and food factory. In addition to freezing food for longer shelf-life or serving hot, food may be cooked and chilled for microwave meals or kept in buffet food warmer. According to your business type, ANKO's sales engineers will provide the most suitable food production solution to ensure food made by ANKO's food machine is delicious.

With the growth of demand, ANKO's value is to help clients increase efficiency and seize food business opportunity through our food production solutions.

You can find more successful cases that have helpful food solution information you need below or send an inquiry to us now!

The client has production lines for bakery and ethnic food, including baozi, siomay, hargao, bread, etc. In order to provide the most fresh and best quality food to customers, they have food factories, central kitchens, packaging production line, cooling and frozen facilities. Because their present products stably make profits, they plan to expand the other Chinese dim sum production line to produce spring roll. Hope it can create a new market. Prior to this expansion, the client bought several machines from ANKO for making baozi and satisfied with machine's quality and ANKO's after-sales service, so that ANKO spring roll wrapper machine, which production capacity is high and stable, is exactly what they want. Therefore, it is our pleasure to cooperate with them and satisfy their requirements.

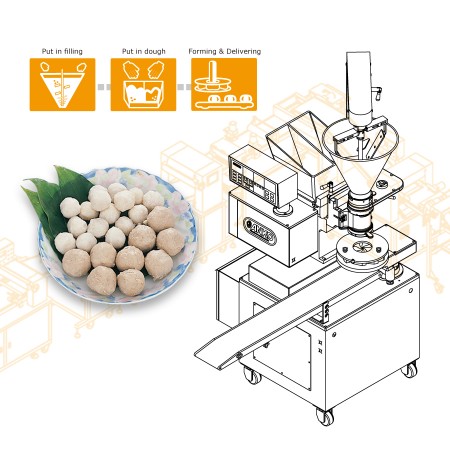

The client has two fishing vessels and two fish processing plants to process the six-ton daily catch. One plant is dedicated to mince fish into fish paste, and the other plant is for the production of fish balls and fish products. He purchased a HLT-700XL Multipurpose Filling & Forming Machine and a SD-97W Automatic Encrusting and Forming Machine from ANKO. The HLT-700XL is used for producing deep-fried fish snacks — a new offering made of springy fish paste with a crispy wrapper. And the SD-97W is for making stuffed fish balls. The client's new plant covers 10,000 square meters and employs around 50 people. Their products are mainly sold to local supermarkets in Indonesia such as Carrefour.

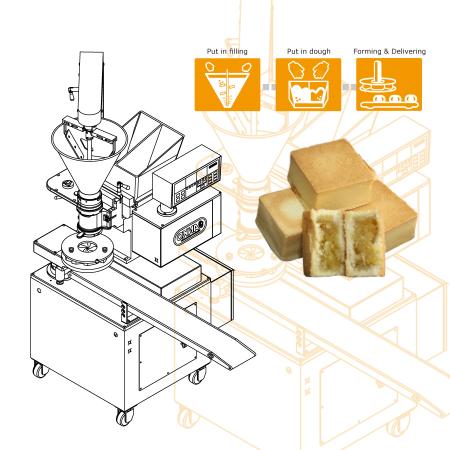

It is a food and beverage company, producing frozen and fresh food, and owning over 30 casual dining restaurants. Most materials of the company's products are from its own farms. With the concept of providing organic food and additive-free products to consumers, the owner insists on growing plants with organic farming. The owner found that Taiwanese pineapple cake is very popular and delicious, so he decided to produce pineapple cakes and sell them in his retail stores. However, he had no experience in making pineapple cakes. After having a discussion, we proposed a pineapple cake tailor-made total solution to him, including pineapple cake recipe, equipment, and training. Finally, he entrusted ANKO with the new product line.

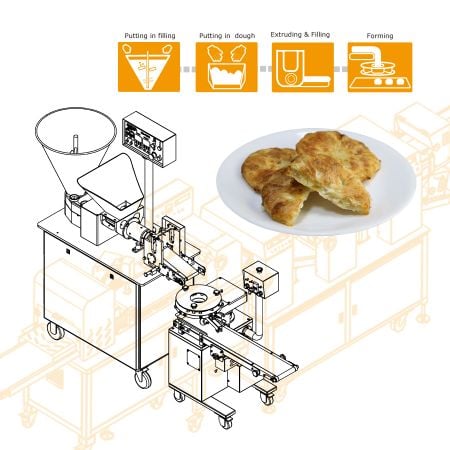

To increase capacity and standardize products are the main issues that drive food manufacturers and restaurant owners, including this client, to switch from manual to automatic production. The dumplings served in the company's restaurant chains were made by hand in its own central kitchen. Consumers really liked the handmade dumplings, but 'sold out" was the most important issue with which the company had to deal. Moreover, the size, weight, and taste of handmade dumplings might vary from batch to batch. Using a dumpling maker can both improve capacity and achieve standardization. Therefore, he chose us as the solution provider for the automatic production of dumplings. He also wanted to serve deep-fried dumplings and steamed dumplings to satisfy customers' appetite after increasing capacity.

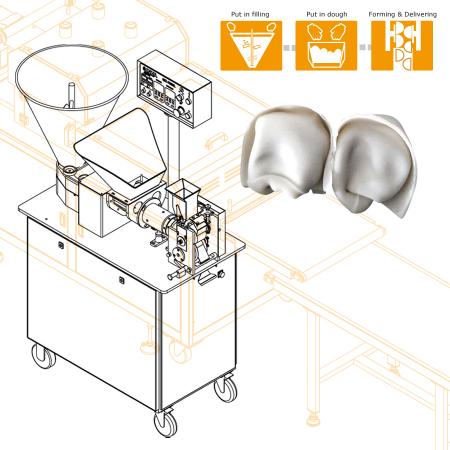

20 years ago, a Chinese restaurant opened, serving Shanghai style dim sum which then became popular with the local people. However, the issues of labor shortage, limited capacity, and workload drove the owner to make a change. During his visit to ANKO, he had good experience with ANKO's machine trial service. During the visit, both of us could have a better understanding of each other. Based upon his ideas, concerns, and needs, we customized two forming molds to help him mass-produce shanghai wontons that were complicated to fold by hand. With ANKO's HLT-700XL, now the owner doesn't bother to recruit and train cooks and can increase capacity to meet demands.

The owner's kompia is so delicious that people are willing to travel a long way to his store in a rural area. However, 1,000-1,200 kompias made by five people a day were not able to meet the demand. That made people feel disappointed and sometimes brought customers into conflict. The client contacted ANKO's Malaysian distributor for SD-97SS, but after a machine trial, ANKO's engineer thought that the HLT-700XL and EA-100KA was more suitable for kompia dough that was firmer for making crispy kompia, while the SD-97SS is suitable for soft fermented dough for creating fluffy texture. Therefore, our engineer immediately decided to use HLT-700XL and EA-100KA to make some samples. With the samples and ANKO's soft power of food and ingredients, the client had complete confidence in us and placed an order.