Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

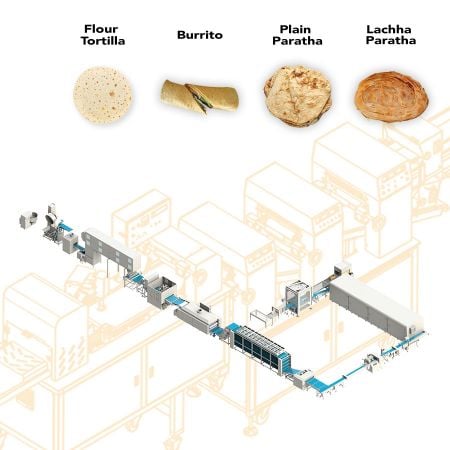

ANKO has newly configured four Integrated Production Lines to meet the manufacturing needs of Flour Tortillas, Burritos, Plain Parathas, and Lachha Parathas. More than 1.5 billion people worldwide consume these products, representing a major global market. Globally, medium-sized food manufacturers make up the majority of the industry. However, when faced with surging order volumes, labor shortages, and mounting competitive pressure, these businesses often need to transition toward scaled and automated production. Flatbread production is more complex than other foods, requiring consistent quality and efficient output. ANKO’s solution integrates dough feeding, forming, packaging, inspection, carton sealing, and environmental monitoring into one streamlined system—helping clients upgrade their production with ease.

This ANKO client is a well-known food manufacturer in Bangladesh, and their business scope includes multiple food fields. They have been using semi-automatic equipment to produce Paratha to supply their domestic market demand. To expand their Paratha sales internationally, this client purchased ANKO’s fully automated food machines to produce an estimated 100,000 pieces per day in order to meet the global market demand. This ANKO return customer is confident in our high-quality machine performance and the professional support services we provide. Our team customized a Triple Line High Capacity Paratha Production Line for this company. With the assistance of ANKO’s Bangladeshi local distributors, this client visited our Taiwan headquarters to conduct trial machine operations, and the results successfully met the client’s required production requirements and food specifications.

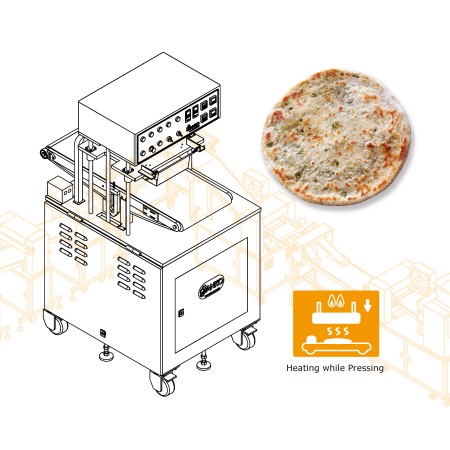

An ANKO Client has been producing a variety of high-quality Roti (Indian style flatbread) and has established a distribution system in wholesale, retail, and supermarkets. During the COVID-19 pandemic, the local food market in the Netherlands experienced a dramatic increase in demand for frozen Roti, as more people were cooking at home. While the company’s production capacity was not able to meet the new demand, they reached out to ANKO and requested assistance to help them transition into automated production. Due to the pandemic and travel restrictions, this client mailed their ingredients to Taiwan and ANKO started production trials and communicated with this client remotely. ANKO’s engineers customized a production solution utilizing ANKO’s SD-97W Automatic Encrusting and Forming machine and APB Pressing and Heating machine for automated Roti production. This production line is compact and highly efficient which exceeded the client’s expectations.

An ANKO client is a major food manufacturer in Kenya and had a business expansion plan to increase market share and revenue in the local food business in Kenya. That was why they wanted to invest in creating a new product - East African Chapati (Paratha). The client learned about ANKO from the Gulfood Expo and compared various suppliers and decided ANKO’s products and services were the best. When they initialed the order, ANKO worked diligently to provide customized production line and all the necessary support needed for a successful implementation!

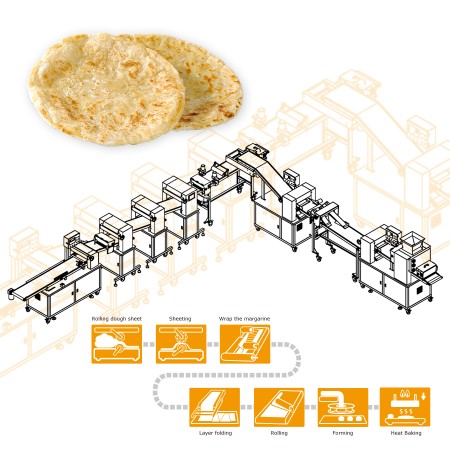

The client supplies Danish pastries, chapatis, Mille-feuilles and cinnamon rolls, and they wished to upgrade their production capacity in order to increase the sales in fast-food chains.

This company is a food supplier that specialized in providing frozen prepared foods in India. They contacted ANKO for food processing equipment solutions due to increasing demands. The quality, weight, and size of the handmade paratha aren't consistent and the production capacity is low. It would therefore be a total solution if paratha production equipment can solve all problems.

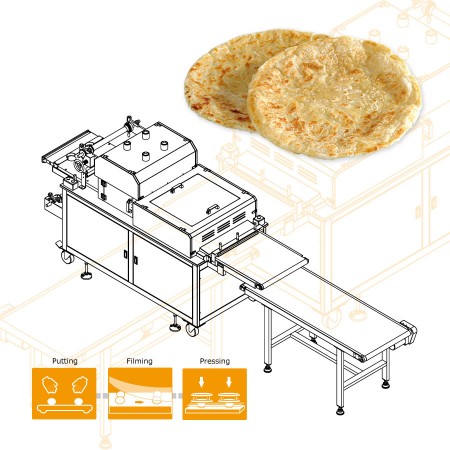

Muslim is the major population in Middle East, which shapes their food culture, halal food. Also, in a fast-paced environment, frozen food becomes one of favorite items in shopping lists. The client is also running business about frozen food like kubba, samosa, chicken fingers. When every producer is keen to develop product differentiation in size or new product, they need a machine supplier who can shortly customize machine to meet individual requirement. ANKO is a professional team; more than half of employees are experienced engineers in which there are over 20 RD engineers. Through interior integration, we quickly react to modify machine as required. Therefore, the client asked ANKO to customize large size filming and pressing machine for him.

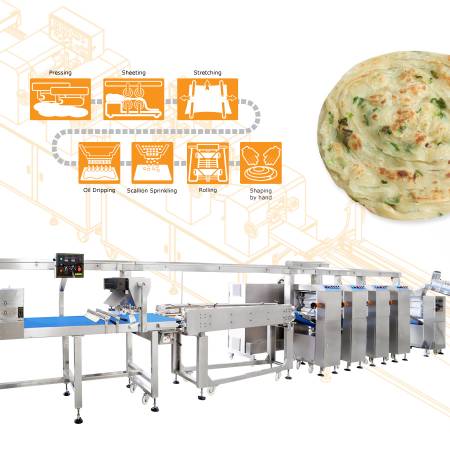

The client is a frozen food wholesaler. He would like to save labor cost and increase productivity. He found ANKO to seek the best solution. ANKO focuses on keeping handmade taste when a client transforms manual production into machine production. For example, the client has produced green scallion pie, which is complicated made by hand. When he tried to produce his products by machine, instead of by hand, one of the difficulties is that the machine cannot repeatedly roll dough into a circle. Therefore, we've made many efforts to eliminate this kind of differences between handmade process and machine-made process. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

The client had been processing aquatic food products on the beginning of his business and becoming a leader in local food industry. Then, the client established a new plant to produce flour and pastries. Bangladesh is a dense area in which there are tremendous opportunities in the frozen food market. Because paratha is a common food in this area and the client has a flour factory, he decided to run a paratha production line. By word of mouth, they approved ANKO's ability to plan a turnkey. Plus, our advantage is the flexibility of planning production line and installing machine, depending on the client's space. Therefore, they believe in our machines and services, purchasing the whole production line from dough mixer to food packaging from ANKO.

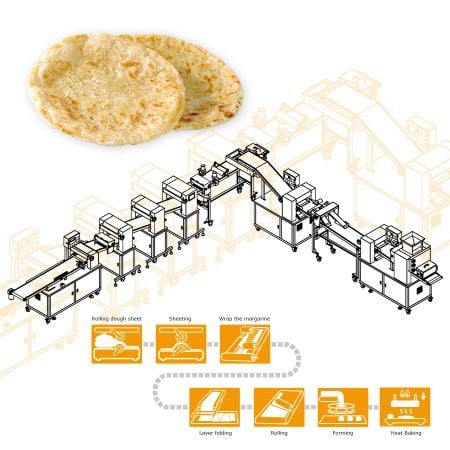

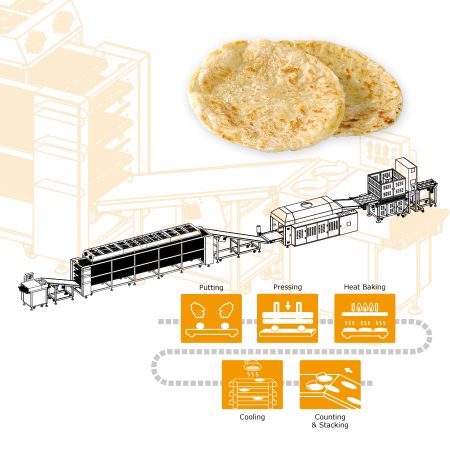

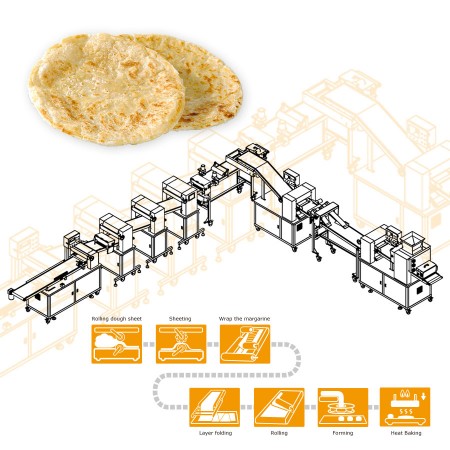

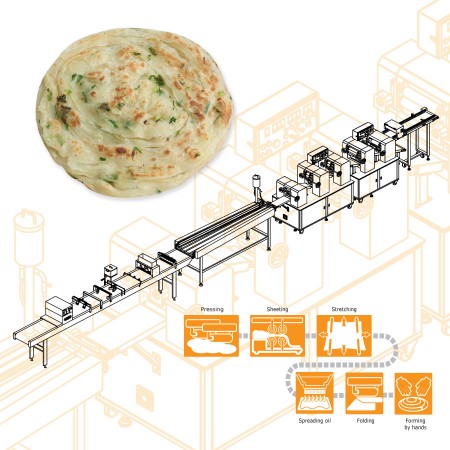

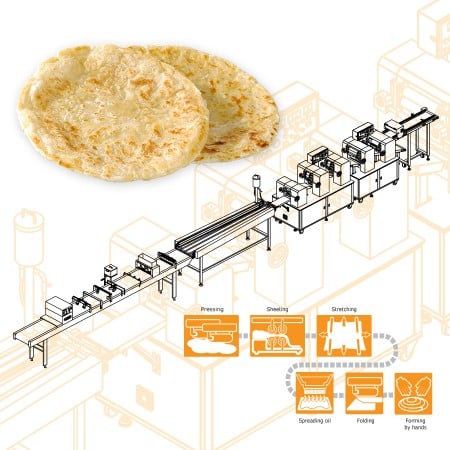

The client is a frozen food manufacturer, producing Indian food and selling to grocery stores and supermarkets. The growth of demand for paratha urges the client to seek automatic production line so as to reduce labor cost and increase productivity. The texture and taste of lachha paratha is layered and crispy that ANKO R&D team understands and keeps the characters in machine-made products. Our machine is capable of stretching dough to be pervious to light as well as producing products up to 2,000 pieces in one hour. The client satisfied those advantages of the machine so that they decided to cooperate with ANKO. (Note: LAP-2200 is no longer available. The updated model is LAP-5000. Please feel free to contact us for more information.)

The client's company had gained a firm foothold in India and then he planned to expand into the U.S. market so that having accurate food quality control and standardization, product line extension, productivity improvement are essential. He compared ANKO with other food machine suppliers and found ANKO is superior to them. ANKO has higher market share in India, offers wrapper and filling recipe to meet individual need, and has years' experience in designing food production routes and supply chain integration. Finally, he chose ANKO as their business partner.

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production has been lingering in your mind but you just don't know where to start. Then, you start searching on the Internet. You might find many consulting firms; you might find a lot of food machine companies including ANKO. You might be wondering which kind of company you should call. We have our own factory, so we know making a complete factory plan is important to improve efficiency. Therefore, we offer not only a machine but also consulting services. When your inquiry comes in and our sales clicks on, we assure you can follow us to have a forming machine that suits your needs and front- and rear-end equipment, recipe, machine trial, training and after sales services.