Meeting the Needs of 1.5 Billion Consumers Worldwide: ANKO Develops Integrated Production Lines for Flatbread Manufacturers

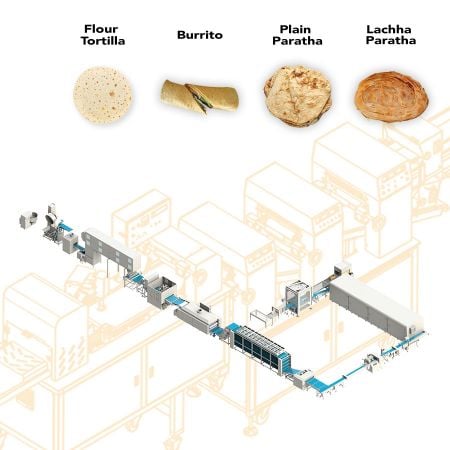

ANKO has newly configured four Integrated Production Lines to meet the manufacturing needs of Flour Tortillas, Burritos, Plain Parathas, and Lachha Parathas. More than 1.5 billion people worldwide consume these products, representing a major global market. Globally, medium-sized food manufacturers make up the majority of the industry. However, when faced with surging order volumes, labor shortages, and mounting competitive pressure, these businesses often need to transition toward scaled and automated production. Flatbread production is more complex than other foods, requiring consistent quality and efficient output. ANKO’s solution integrates dough feeding, forming, packaging, inspection, carton sealing, and environmental monitoring into one streamlined system—helping clients upgrade their production with ease.

Flour Tortilla / Burrito / Plain Paratha / Lachha Paratha

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Four Integrated Production Lines Tailored to Product Characteristics—Achieve Efficient Scale-Up and Transformation

Each type of flatbread requires different dough resting times and temperature-humidity conditions. Therefore, the process design and machine configuration vary across the four production lines. ANKO developed four Integrated Production Lines tailored to each product’s characteristics, helping clients boost production capacity, optimize workflow, and meet specific product standards. Depending on plant size, key machines can be adjusted to fit available space and streamline manpower allocation, maximizing production efficiency.

1) Integrated Flour Tortilla Production Line (Forming Machine: TT-3600)

Flour Tortillas are made primarily with wheat flour, offering good extensibility and elasticity. Proper dough resting is essential for smooth operation on automated lines. Therefore, the front-end of this line includes a dough divider and resting machine, allowing the dough to rest for about 10 minutes before entering the TT-3600 Tortilla Production Line. This line handles 6- to 10-inch Tortillas and carries out hot pressing, baking, cooling, stacking, and counting—followed by packaging and other back-end processes.

2) Integrated Burrito Production Line (Forming Machine: BR-1500)

To automate Burrito production, the key step is softening the Tortilla so it can be folded without springing back. The line starts with a Tortilla softening and transfer machine, preparing the base for the BR-1500 Burrito Forming Machine, which performs filling, folding, and rolling. This setup is configured for individual 150g Burrito packs. Customization is available upon request.

3) Integrated Plain Paratha Production Line (Forming Machine: LP-3001)

Plain Parathas are layered and chewy, made from medium- or high-gluten flour combined with ghee, giving them the elasticity required for repeated rolling and folding. The LP-3001 Automatic Paratha Production Line forms dough sheets, performs pressing and sheeting, automatically folds in the ghee, and stacks the layers before repeating the pressing and sheeting steps. The dough is then rolled and divided using the EA-100KA Forming Machine. A resting period of 20 to 40 minutes is required to relax the gluten and prevent shrinkage. Therefore, ANKO has specially designed a dedicated resting zone to ensure smooth production flow and enhance the stability of the pressing and forming processes.

4) Integrated Lachha Paratha Production Line (Forming Machine: LAP-5000)

Lachha Paratha dough is lower in oil but highly elastic, relying on stretching, oil layering, and air trapping during folding to achieve its signature flaky texture. Gluten strength must support these steps. The LAP-5000 Lachha Paratha Production Line includes pressing, sheeting, stretching, and oil dripping, followed by a 35-meter resting conveyor that allows 8–10 minutes for oil solidification before rolling. A second resting stage ensures gluten relaxation, preventing shrinkage before the dough enters the filming and pressing machine to reach the required product size.

Solution 2. How Should Back-End and Quality Control Equipment Be Configured? Six Modular Solutions for Different Factory

When clients require integrated production solutions, ANKO initiates a one-on-one consultation process to understand their product specifications, capacity goals, investment budget, and available factory space. This information allows us to create an initial production layout and equipment configuration. After confirming the core process, we tailor solutions based on the specific production characteristics of each flatbread product, incorporating ANKO’s proprietary technologies and a wide range of automated equipment to deliver a solution that best fits the client's needs. The integrated line can be paired with the following back-end and quality control equipment.

1) Packaging Equipment – Automatically packs products according to size and quantity, supporting various packaging formats including single-pack or multi-pack options.

2) Weight Inspection – Automatically detects whether each package falls within the acceptable weight tolerance; only those within range are approved for dispatch, ensuring consistent product quality.

3) Foreign Object Detection Systems – Optional integration with X-ray or metal detectors to reject contaminated products and reinforce food safety controls.

4) Robotic Arms – Replace manual handling to reduce contamination risks; models can be selected based on product weight and handling speed requirements.

5) Automatic Carton Sealers – Seal cartons automatically based on package size and quantity per box, enabling a streamlined, labor-saving shipping process.

6) Environmental Monitoring Devices – Monitor and manage temperature and humidity levels according to product requirements, with smart alerts sent to mobile devices for real-time oversight of factory conditions.

Solution 3. Successfully Assisting a Bangladeshi Client with a Triple Line High Capacity Paratha Production Line—Accelerated Integration and Fast Implementation!

In 2024, ANKO successfully implemented a "Triple Line High Capacity Paratha Production Line", helping a Bangladeshi client achieve a daily output of 100,000 pieces. Given the client’s limited factory space, the 1-meter dough sheet produced by the LP-3001 was split into three separate lines, each connected to an EA-100KA Forming Machine and a PP-3 Automatic Filming and Pressing Machine. This customized solution showcases ANKO’s strong integration capabilities and extensive experience. To enhance operability and convenience, equipment positions and heights were adjusted, and additional dough-feeding devices and sensors were installed to reduce labor requirements. Moreover, we successfully optimized the dough’s lamination—from the client’s original 6 layers to 36 layers. This solved the issue of dough shrinkage, and the customer expressed great satisfaction. (View the full case study by clicking the image on the left.)

ANKO Is More Than a Machine Supplier—We’re Your Trusted Strategic Partner for Business Expansion!

ANKO provides Integrated Production Lines tailored to your specific needs, also customized upgrades to enhance your existing equipment. Our integrated solutions are designed to maximize output and ensure consistent product quality, helping you boost production efficiency. Beyond machinery, we also prioritize your overall investment benefits. From accelerating return on investment and ensuring compliance with local regulations and hygiene standards, to offering localized training and after-sales support—these are all key factors in helping you scale up. In addition to our four Integrated Production Lines, we also provide one-stop production solutions for other flatbread products, such as Chapati, Roti, Stuffed Paratha, and Parotta. Please feel free to contact us for more information.

Integrated Flour Tortilla Production Line (SOL-TTL-T-1)

Product name: Flour Tortilla / Product weight: 80 g / Capacity: 3,000 pcs/hr / Labor requirement: 4–5 people / Min. space required: 39,550 (L) x 16,000 (W) x 3,540 (H) mm

Integrated Burrito Production Line (SOL-BRT-T-1)

Product name: Burrito / Product weight: 150 g / Capacity: 3,000 pcs/hr / Labor requirement: 4–5 people / Min. space required: 17,500 (L) x 14,500 (W) x 2,600 (H) mm

Integrated Plain Paratha Production Line (SOL-PPT-T-1)

Product name: Plain Paratha / Product weight: 65 g / Capacity: 10,800 pcs/hr / Labor requirement: 19–20 people / Min. space required: 37,000(L) x 19,200(W) x 2,900(H) mm

Integrated Lachha Paratha Production Line (SOL-LPT-T-1)

Product name: Lachha Paratha / Product weight: 65 g / Capacity: 5,000 pcs/hr / Labor requirement: 13–14 people / Min. space required: 32,600(L) x 23,100(W) x 2,900(H) mm

Note: The configurations and components of the above Integrated Production Lines are for reference only. The actual designs will be customized to meet your actual production requirements.

- Solution Proposal

Leading the Food Machine Market! ANKO’s Integrated Production Lines Set New Industry Trends

ANKO did

ANKO’s food machines have earned the trust of thousands of customers worldwide! With successful sales in 114 countries and a steady release of new products each year, ANKO is a recognized leader in the food equipment industry. In 2024, we launched Integrated Production Lines for Dumplings, Shumai, Spring Rolls, and Xiao Long Bao. This year, we’ve expanded our offerings to include Integrated Lines for Tortillas, Burritos, Plain Parathas, and Lachha Parathas—empowering our clients to take on more orders through seamless integration solutions.

ANKO can help you more

With over 48 years of global market experience, ANKO is committed to providing quality food production solutions. We prioritize user-friendly experiences, professional consulting services, and deep insights into evolving food trends, making us your most reliable partner in the food business. To learn more about our Integrated Production Lines, please fill out the inquiry form below—we’ll get in touch with you shortly.

- Category

English

English