World's First Punjabi Samosa Forming Machine! ANKO and UK Client Co-Create a New Era in Food Production

This UK-based Indian food manufacturer, specializing in Punjabi Samosas, relied on manual labor to produce 1,000–1,500 pieces daily. With growing competition in the UK's Indian food market, scaling production and boosting revenue became increasingly urgent. After an in-depth consultation, ANKO found no existing machine could mass-produce the pyramid shape of traditional Punjabi Samosas. To help the client gain a competitive edge, ANKO spent over a year developing the world's first PS-900 Punjabi Samosa Forming Machine. Throughout development, the client visited ANKO's Taipei headquarters for filling tests and function validations. This breakthrough enabled automated production, reduced labor costs, and created a differentiated product, strengthening their market position and accelerating brand growth.

Punjabi Samosa

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Industry's Only Solution! ANKO PS-900 Ensures Both Pyramid Shape and Food Safety

India, the world's most populous country, has shown strong market growth potential according to several research institutions. With the rising Indian diaspora in countries like the United States, the UAE, the United Kingdom, and Malaysia, the traditional Indian snack industry is also expanding rapidly. ANKO's market research revealed that no current equipment could produce pyramid-shaped samosas, and with specific customer demand, ANKO developed the PS-900 Punjabi Samosa Forming Machine. This industry-leading machine offers automated production of authentic pyramid-shaped samosas through a five-station design: dough placing, pressing, filling, sealing, and product discharge. The machine replicates the layered texture of handmade folding to create products with a traditional appearance and mouthfeel. In terms of food safety, automation ensures consistent product quality and hygiene, effectively minimizing risks and safeguarding the manufacturer's reputation.

Solution 2. Boost Your Punjabi Samosa Production and Quality! ANKO Delivers Must-Have Automated Equipment for Manufacturers

Most Punjabi Samosas on the market are still handmade, with an average output of 300 to 350 pieces per hour. With ANKO PS-900 Punjabi Samosa Forming Machine, hourly production can reach up to 900 pieces, reducing the need for 1 to 2 workers. In the face of rising labor costs, this not only saves on personnel expenses but also simplifies training thanks to the machine's user-friendly operation—ideal for small to medium-sized businesses. The PS-900 is compatible with common handmade samosa recipes, handling dough with up to 60% oil and water content and a thickness of 2 to 3 mm. Its 42-liter filling system flexibly accommodates various ingredients while preserving chunks up to 10 mm—such as potato cubes, green peas, or corn—ensuring smooth forming and complete sealing. This allows producers to pursue efficiency without compromising product quality and taste.

Solution 3. Achieve One-Stop Punjabi Samosa Production! The PS-900 Fully Meets Production Needs

The PS-900 is the core equipment for producing Punjabi Samosas. If customers wish to reduce labor requirements in their production line, ANKO can also plan for conveyors, robotic arms, automatic box loading, and unloading equipment according to their needs. This solution addresses labor shortages, rising wages, and high staff turnover. Additional equipment for Punjabi Samosa production, such as ingredient preparation, dough production machines, fryers, packaging machines, and X-ray inspection devices, can also be provided to help customers create a highly automated production line that meets all production needs from the front to the end of the process. For European customers using the PS-900 machine, CE protection devices can be purchased as needed.

ANKO leads the industry with the launch of the "PS-900 Punjabi Samosa Forming Machine," which authentically presents the traditional pyramid shape. With a production capacity of 900 pieces per hour, the machine features a simple design that allows for quick disassembly, speeding up daily cleaning, maintenance, and repairs. It is the ideal equipment for producing Punjabi Samosas.

Food Equipment Introduction

- Place the wrapper in the machine

- The machine automatically presses, fills, and seals

- Automatically formed into a Punjabi Samosa shape

Flexible Solutions for Standardized and Customized Punjabi Samosa Production

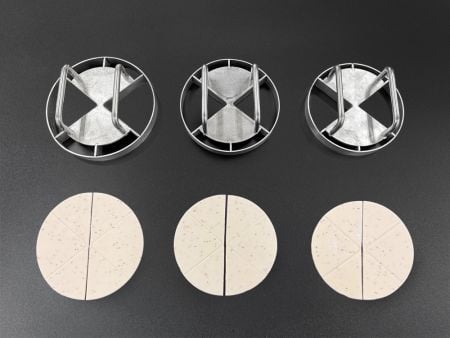

ANKO PS-900 Punjabi Samosa Forming Machine can produce samosas weighing 60g, 70g, or 80g, using wrapper sizes of 160mm, 170mm, or 180mm. By switching size kits and modules, the machine easily adjusts to produce different sizes to meet diverse production needs. The typical Punjabi Samosa size on the market ranges from 60g to 90g. For customized sizes, ANKO provides expert evaluations and customization services. Additionally, the molds used in the PS-900 meet FDA-certified materials, ensuring all food-contact parts comply with food safety regulations. It offers excellent stability and durability, helping businesses achieve consistent production, enhanced quality control, and adapt to diverse market demands.

- Machines

-

PS-900

ANKO PS-900 Punjabi Samosa Forming Machine is the world's first equipment designed to produce pyramid-shaped Punjabi Samosas. With a production capacity of 900 pieces per hour, the machine automatically forms samosas once dough wrappers are loaded. Product size can be customized based on customer requirements, and the simplified operation makes it easy even for foodservice beginners to manage. Requiring only 1–2 operators and occupying a compact footprint of approximately 2 meters in length and 2 meters in width, the PS-900 is especially suitable for small to medium-sized businesses. For customers with higher automation needs, we also offer optional solutions for automated dough placement and product pickup. Additional equipment such as dough sheet production units, fryers, packaging machines, and X-ray inspection systems can be integrated to achieve stable, high-quality output.

- Country

United Kingdom

United Kingdom Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in United Kingdom with advanced automated food production technology for making Spring Rolls, Wonton, and Rasgulla. We also offer integrated solutions for popular foods such as Dumplings, Samosa, Kibbeh, Panzerotti, Paratha, Momo, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Punjabi Samosa (पंजाबी समोसा), commonly known as curry puff in Chinese, originated in India and is a beloved traditional street snack. It is well known for its distinctive pyramid shape, golden crispy crust, and fragrant, flavorful filling made primarily of potatoes and green peas mixed with Indian spices. As one of the most iconic types of samosas, it has gained popularity worldwide. In the late 19th century, large numbers of Indian immigrants—mostly of Punjabi descent—moved to the UK, bringing the delicious samosa with them. According to recent statistics, the Indian population in the UK now exceeds 2 million, making it the largest non-White ethnic group in the country. As a result, Punjabi Samosas have gradually become part of the UK's mainstream food culture and are widely available at restaurants, takeaway shops, and supermarket frozen sections.

Today, major UK supermarkets such as Tesco, Sainsbury's, and Morrisons carry popular samosa brands like Shana, Humza, Cofresh, and Royal. These brands offer ready-to-eat or microwaveable products, often accompanied by dipping sauces for added convenience. In addition to the classic potato filling, varieties like vegetable, lamb, and chicken are also available, catering to vegetarian, halal, and health-conscious consumers, and making samosas a staple in the UK frozen food market.- Handmade Recipe

-

Food Ingredient

Wrapper: All-purpose flour/Carom seeds (Ajwain)/Ghee/Salt/Water, Filling: Potatoes/Green peas/Vegetable oil/Green chili/Ginger chunks/Cumin powder/Cilantro/Fennel seeds/Amchur (dried mango powder)/Turmeric/Salt

Dough Preparation

(1) Combine all-purpose flour, carom seeds (ajwain), and salt in a mixing bowl. (2) Rub ghee into the flour mixture with your hands until it reaches a coarse, crumbly texture. (3) Gradually add water and knead until a firm yet pliable dough forms. (4) Cover the dough with a towel and let it rest for at least 30 minutes. (5) Divide the dough into seven equal portions and roll each into a ball. (6) Roll out one dough ball into a 5-inch circle. Stretch both ends slightly to form an oval. (7) Cut the oval in half to create two semi-oval wrappers. Repeat for all dough balls.

Filling Preparation

(1) Heat oil in a pan, add green chili and ginger, and sauté for about 30 seconds. (2) Add cumin powder and cilantro, then stir in fennel seeds and turmeric. (3) Add the boiled potatoes and mix well, followed by green peas. Stir until the peas are evenly mixed into the potatoes. (4) Season with salt and cook for 3–5 minutes until heated through. (5) Before turning off the heat, gently mash the potatoes with a spoon. (6) Allow the filling to cool before using.

Product assembly

(1) Take one wrapper and brush the edges with water. Overlap the two straight sides to form a cone shape, sealing the seam tightly. (2) Fill the cone with the prepared potato filling. Seal the top edge by pressing it together. Slightly fold the center seam inward to give the samosa its signature pyramid shape. (3) Deep-fry the samosas until the crust turns golden brown. Serve hot.

- Downloads

English

English