Transforming Innovative Business Opportunities! ANKO Helps South African Manufacturer Achieve Chicken Pie Automation and Product Differentiation

This client has been operating a food factory in South Africa for over 30 years, specializing in high-quality frozen foods, including samosas, rollups, and waffles. With strong brand recognition in the local market, the client first visited ANKO’s booth at the IBA exhibition for an initial consultation. At that time, they had no immediate need for automation and did not pursue further contact. A year later, as their existing product sales stabilized, they decided to develop a new product. After conducting market research, they discovered that Meat Pies are highly popular in the region. This led them to reconnect with ANKO to explore automation solutions. With our professional assistance, we customized unique patterns for their Chicken Pies, successfully differentiating their products in the market and enhancing their brand identity.

Chicken Pie

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Breakthrough in Details! Optimizing Production Processes to Resolve Chicken Pie Forming Issues

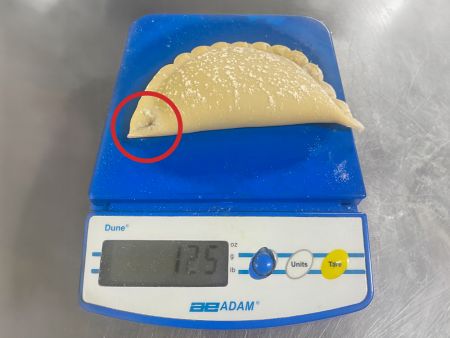

This client’s Chicken Pie mold was designed with a logo and two distinct patterns, with each product weighing 125 grams. To ensure precision, the ANKO team first utilized 3D printing technology to create a prototype. After the client confirmed the production test runs, we proceeded with the official mold development. Upon machine installation in South Africa, our experienced professional team conducted on-site training. During production, an issue was identified: the first angle of the Chicken Pie was not formed properly, affecting the embossed pattern's consistency. After investigation, we determined that the issue stemmed from the interaction between the product and the conveyor belt, leading to uneven patterns. We then identified the key operational adjustments...(Contact ANKO now for more details!)

With our professional guidance, the forming issue was successfully resolved, ensuring uniform patterns and consistent product shape. This not only stabilized product quality but also enhanced production efficiency, enabling a smooth transition to mass production.

Solution 2. Professional Expertise Shapes the Perfect Chicken Pie! Mastering the Key Steps of Frying and Baking in One Go

After frying and baking, the client experienced issues with the Chicken Pies, such as wrapper breakage and bursts. The ANKO team first reviewed the filling's properties and weight, followed by an examination of the extrusion process to gradually identify the causes. Since frying and baking are two distinct cooking methods, each with different heating rates and surface areas, we focused on optimizing both processes. For frying, we experimented with varying oil temperatures and frying times to determine the optimal cooking technique. For baking, we made adjustments across multiple variables, including oil, water, flour, filling ratios, and dough thickness, while also refining temperature control and timing during the baking process. After several trials, we successfully resolved the wrapper breakage and bursts issues. Whether fried or baked, the product's appearance was flawless, leaving the client highly satisfied.

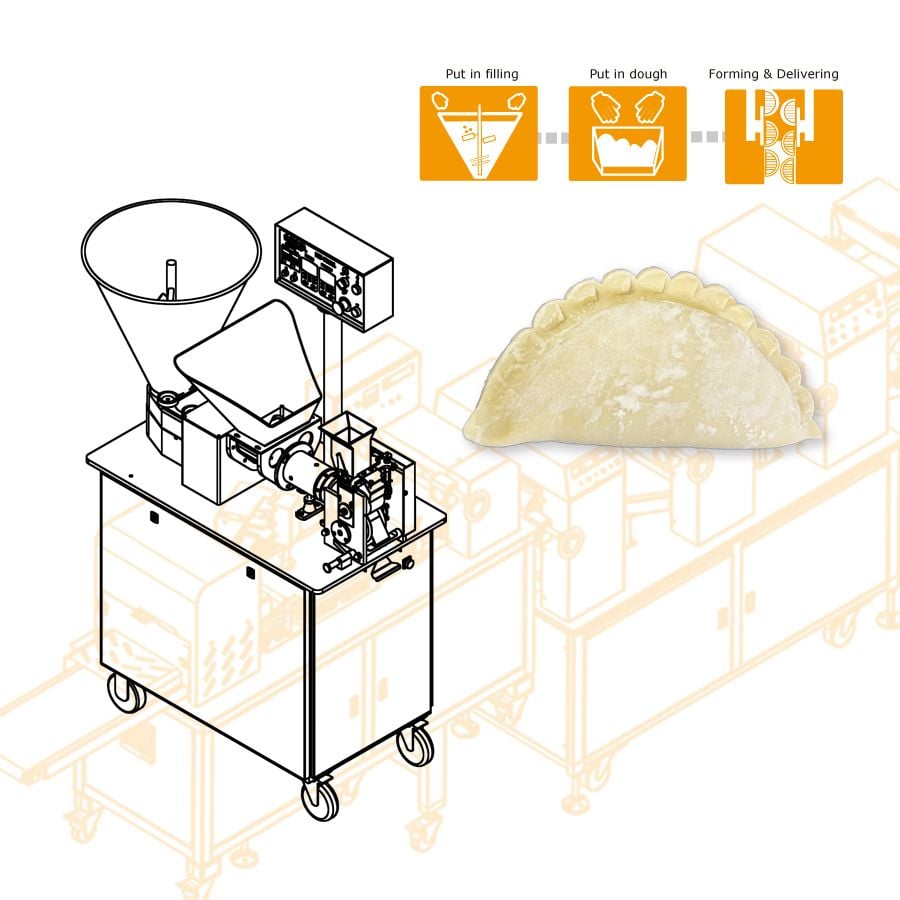

The client purchased the HLT-700XL Multi-Purpose Filling & Forming Machine to produce 125g Chicken Pies, achieving a production capacity of approximately 4,000 to 5,000 pieces per hour. The machine is easy to operate, making it accessible even for beginners. It is suitable for small to medium-sized food businesses as well as large-scale food factories.

Food Equipment Introduction

- Load the hopper with premade dough

- Load the hopper with premixed filling

- The machine automatically makes Chicken Pies

Customizing Unique Product Shapes! Boosting Meat Pie Market Competitiveness

This case study highlights how ANKO helped the client develop a brand-new product and customized molds, successfully attracting new clients and achieving product differentiation in the market, thereby enhancing brand recognition. In response to the customer’s needs, we created a unique Chicken Pie shape, meticulously planning every stage — from shape design and 3D mold prototyping to test production and stainless steel mold development — to ensure both aesthetic appeal and mass production feasibility. To date, we’ve developed over 700 types of molds, ranging from 2g to 200g, with patterns such as semicircle pattern, shell pattern, nail pattern, ladder pattern and without pattern. The folds, shapes, and sizes can all be customized, and the machine ensures stable production of consistently shaped products with full fillings, enhancing both quality and market competitiveness.

- Solution Proposal

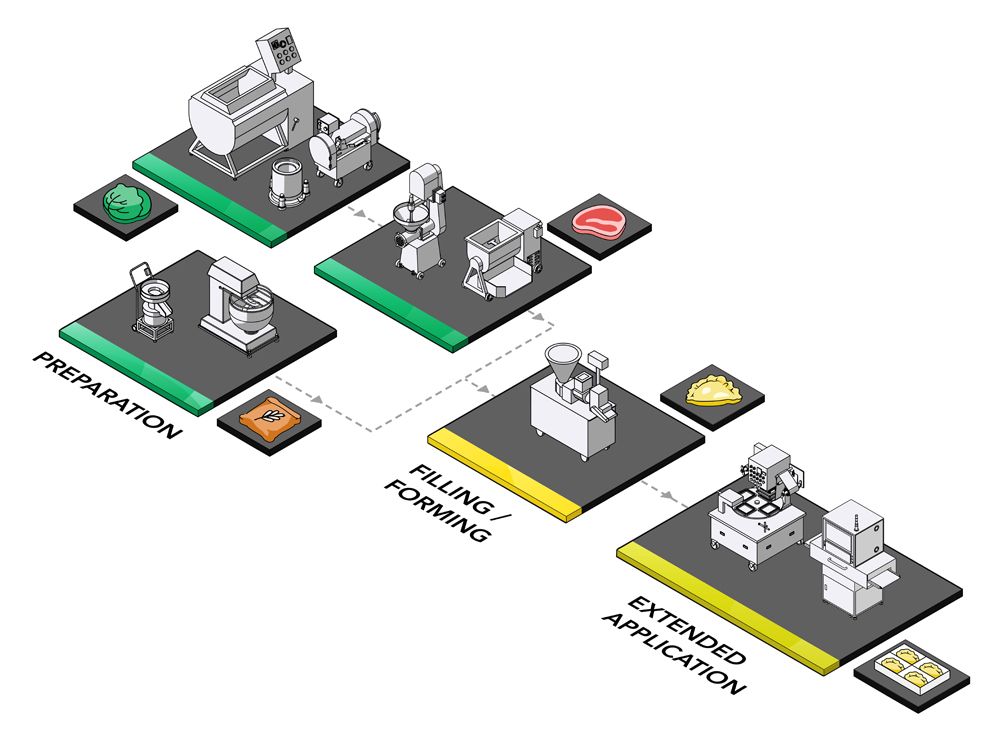

Integrated Production Line: Enabling Automation and Quality Control for Meat Pie Manufacturers

ANKO did

With increasing competition in the global food market, Meat Pie manufacturers face the dual challenge of production efficiency and quality control. Traditional manual production methods can no longer keep up with the growing demand. Therefore, ANKO offers an integrated automation solution, covering from filling preparation, dough processing, forming, cooking, packaging, to X-ray inspection — ensuring a seamless and efficient production process.

ANKO can help you more

ANKO’s expert team tailors production processes and ingredient ratios to suit different types of Meat Pies while optimizing each step based on various cooking methods. Leveraging decades of experience in food machinery, we provide customized solutions by integrating advanced equipment to help manufacturers achieve high-efficiency automation. Click Learn More or fill out the inquiry below, and our consultants will assist you in improving your production capabilities to stay ahead in the competitive market.

- Machines

-

HLT-700XL

The HLT-700XL Multipurpose Filling & Forming Machine can produce up to 10,000 Meat Pies per hour and is suitable for various fillings, including pure meat, cheese, vegetable, and mixed meat-vegetable fillings. It can fill diced meat (0.8x0.8 cm) or cooked potato cubes. The dough used can have a moisture content between 30% and 50%, with up to 20% oil content. By simply changing the forming molds, the machine can produce different products such as dumplings, samosas, raviolis, hargaos, potstickers, and more, offering product diversity. Additionally, it can be equipped with a CE kit for enhanced safety. The machine comes with IoT functionality, allowing operators to monitor the machine's status (such as production data, anomaly reports, and part conditions) via a mobile device remotely. Through big data analytics, the machine can easily predict production capacity and offer recommendations, enhancing the overall production efficiency of food factories.

- Country

South Africa

South Africa Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in South Africa with advanced automated food production technology for making Spring Roll Wrappers. We also offer integrated solutions for popular foods such as Samosas, Spring Rolls, Roti, Dumplings, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

South African cuisine is a rich fusion influenced by European, Asian, and indigenous African culinary traditions, reflecting the country's diverse ethnic composition, including Black, White, Indian, and Asian communities. Against this multicultural backdrop, the South African Meat Pie emerged as a beloved street food, appreciated for its portability and variety of flavors. Whether enjoyed on bustling streets or at family dining tables, Meat Pies have become an essential part of daily life.

South African Meat Pies often incorporate local ingredients such as Chakalaka (a spicy vegetable relish) and chicken, while other popular fillings include cheese and beef, mushroom and chicken, pepper steak, spinach and cheese, and curry. Additionally, regional influences have introduced variations such as Malay-style spiced Meat Pies and versions infused with Masala, a spice blend favored by the Indian community, enhancing the richness of flavors.

Beyond being a breakfast staple or snack, Meat Pies are a must-have at sports events, braai (barbecue) gatherings, and festive celebrations. Well-known brands such as RCL FOODS, King Pie, Country Pie, and Mama’s Pies offer a diverse selection of Meat Pies. As dietary preferences evolve, businesses have also introduced vegetarian and vegan options with fillings like mushrooms, spinach, and soy-based proteins, catering to the growing demand for plant-based alternatives.- Handmade Recipe

-

Food Ingredient

Dough: All-purpose flour/Unsalted butter/Egg/Water/Salt, Filling: Chicken breast/Potato/South African vegetable relish (Chakalaka)/Onion/Garlic/Chicken broth/Salt/Black pepper/Olive oil

Preparing the dough

(1) Mix all-purpose flour and salt evenly. (2) Add diced unsalted butter and rub into the flour until it forms a coarse, crumbly texture. (3) Pour in the egg and water, kneading slowly until a smooth dough forms. (4) Wrap the dough in plastic wrap and refrigerate for 30 minutes.

Filling preparation

(1) Heat a pan with olive oil and sear the chicken until golden brown, then set aside. (2) In the same pan, sauté onions and minced garlic until fragrant, then add potatoes and stir-fry for 2 minutes. (3) Pour in chicken broth and simmer over low heat for about 5 minutes until the potatoes soften. (4) Add the chicken and South African vegetable relish (Chakalaka), mix well, season to taste, and cook until slightly thickened. Let it cool.

Assembly

(1) Take out the dough and divide it into small balls, about 40-50g each. Roll each into a 12 cm diameter round sheet. (2) Place a heaping tablespoon of filling in the center of the dough. (3) Fold the dough into a half-moon shape, seal the edges firmly, and create a decorative pattern using a fork or by hand. (4) Bake or deep-fry until golden brown, and enjoy!

- Downloads

English

English