Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

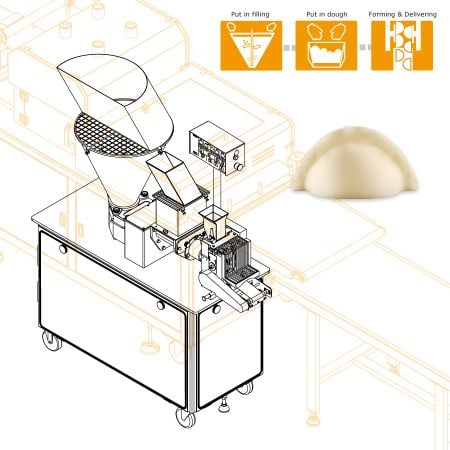

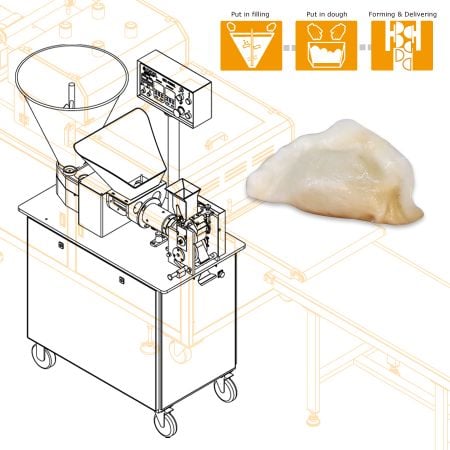

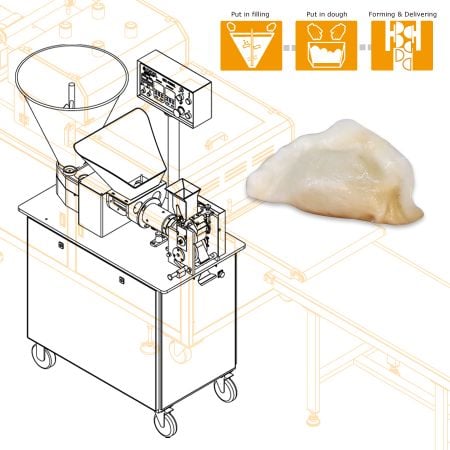

The client operates a central kitchen and restaurant chain in Australia, popular with both locals and tourists. As sales grew and manual production reached its limits, they adopted ANKO’s HLT-700U Multipurpose Filling and Forming Machine to improve efficiency. To meet demand for new flavors and healthier options, the client worked with ANKO to develop custom molds and gluten-free dumplings. Leveraging ANKO’s recipe database and R&D expertise, we ensured stable production, accelerated the product launch, and reduced development costs, helping the client expand their product line and differentiate in the market.

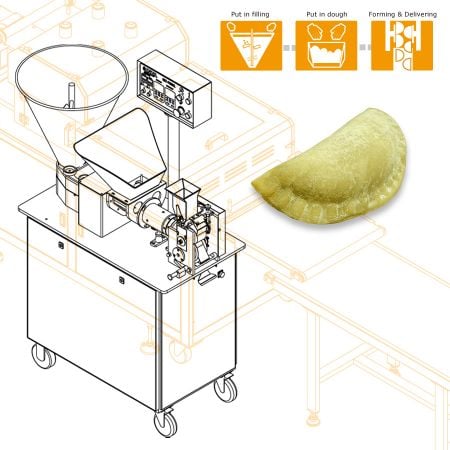

This client has been operating a food factory in South Africa for over 30 years, specializing in high-quality frozen foods, including samosas, rollups, and waffles. With strong brand recognition in the local market, the client first visited ANKO’s booth at the IBA exhibition for an initial consultation. At that time, they had no immediate need for automation and did not pursue further contact. A year later, as their existing product sales stabilized, they decided to develop a new product. After conducting market research, they discovered that Meat Pies are highly popular in the region. This led them to reconnect with ANKO to explore automation solutions. With our professional assistance, we customized unique patterns for their Chicken Pies, successfully differentiating their products in the market and enhancing their brand identity.

This client is a third-generation Chinese American who inherited his grandfather's wholesale food business in the United States. A few years ago, his company had to adjust to accommodate the changes in the overall marketplace and focused on producing and distributing Chinese cuisines. After thorough market research, the client purchased ANKO's HLT-700U Multipurpose Filling and Forming Machine to make authentic Chinese Dumplings. After nearly a year of market testing, which showed promising sales, the client further invested in the ER-24 Automatic Egg Roll Production Line and AF-589 Conveyor Fryer a year later. ANKO's high-quality and durable food machinery has successfully helped clients excel in authentic Chinese food production and become leaders in the market.

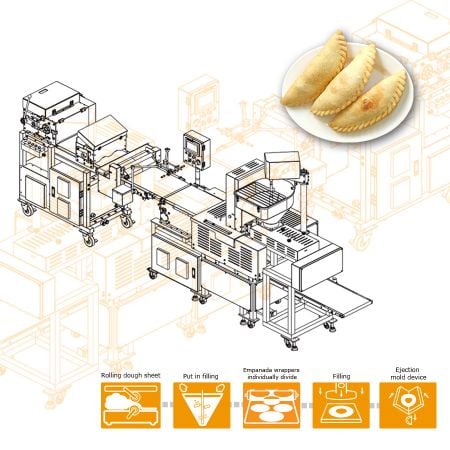

ANKO developed the high-capacity EMP-3000 Empanada Making Machine based on a client’s requirements in the United States. Our team conducted an in-depth analysis of operations at the client’s facility to understand the challenges of their Empanada production. This client needed a machine that could “quickly adapt to market demands while maintaining a high-quality product output.” After multiple test runs and refinement, the ANKO EMP-3000 Empanada Making Machine was launched. This model has a capacity of producing 3,000 Empanadas per hour to help clients’ productivity while saving on labor costs. The easy-to-remove filling system enables continuous production and improves quality control, providing a competitive advantage in food manufacturing.

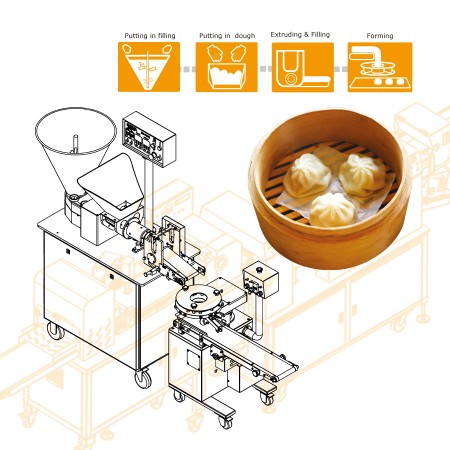

Production automation is inevitable in the food manufacturing industry, and ANKO aims to "assist manufacturers in achieving high production automation goals." In 2024, we launched the "Xiao Long Bao Integrated Production Line" as an integration concept to connect various related production parts. Within a year, ANKO successfully launched the world's first Xiao Long Bao Production Line, supported by our "automated food production solutions" system to further increase food production efficiency and reduce overall labor requirements. ANKO ensures that smart technology is applied to your food production process to increase product quality, consistency, and taste to provide competitive advantages.

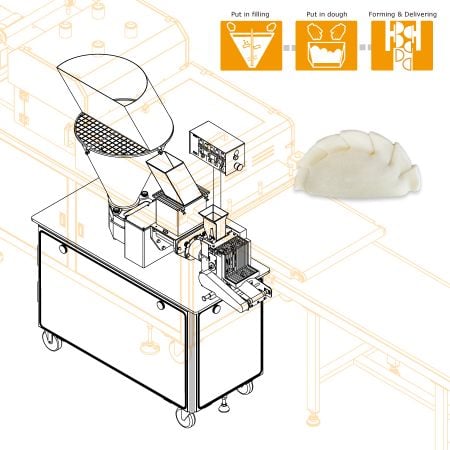

An ANKO client operates restaurants and takeout shops in Australia; they also own a food factory and sell their products in supermarkets. Their food items include Har Gow (Shrimp dumplings), Tang Baos, Dumplings, and Buns. Recently, many food businesses have started using automated production equipment due to labor shortages in Australia. This client is a great example. They purchased ANKO’s HLT-700XL Multipurpose Filling And Forming Machine, EA-100KA Forming Machine, SD-97SS Automatic Encrusting And Forming Machine, and other ANKO machines to produce a wide range of products. They successfully transitioned to automated food production, increased productivity, and resolved labor issues. ANKO’s engineers helped the client maintain the machines and develop new Har Gow flavors successfully.

![ANKO Smart Machine – Pioneering The Integration of Internet of Things [IoT] in Automated Food Production](https://cdn.ready-market.com.tw/aa42f2c9/Templates/pic/m/HLT-700U-Dumpling.jpg?v=db51b6c8)

ANKO regards the IoT system as the foundation for new automated production lines when transforming into an intelligent factory influenced by the Industry 4.0 movement. Our new IoT system was officially introduced in December 2022 after more than three years of development working with system integration companies and various feasibility tests. ANKO introduces our IoT system to the HLT-700U Multipurpose Filling and Forming Machine, to satisfy the increasing market demand for various Dumplings and similar food products that our clients request Worldwide. During the development stage, a Taiwanese client used ANKO’s HLT-700U to produce Dumplings and based on their feedback, our engineers continued to improve our IoT system. After multiple user testing and verification, this client was very satisfied with the advantages ANKO’s IoT system provided to their production needs. ANKO is able to assist businesses transition into smart manufacturing, and we are also proud to have achieved new milestones in smart machine innovation and in the food production process.

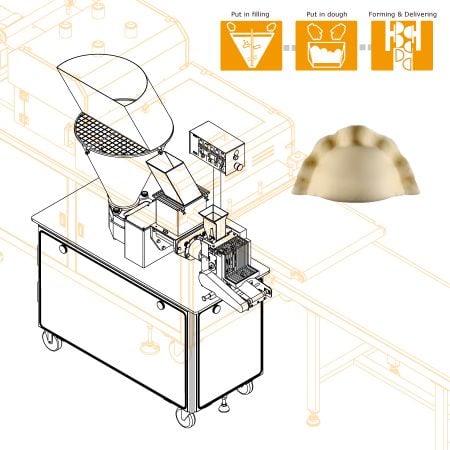

An ANKO client operates a food factory in Poland that specializes in manufacturing frozen foods. Pierogi is one of the national staples of Poland. This client initially relied heavily on producing Pierogi manually, then later switched to automated production using machines from a different manufacturer and encountered unresolved production issues. Then they discovered ANKO’s HLT-700U Multipurpose Filling and Forming Machine, which is perfect for producing Pierogis, and it was supplied by ANKO’s local agent in Poland; it has a CE Marking and comes with Artisanal forming molds that can create dumplings that closely resemble traditional handmade Pierogis. Our client was satisfied with ANKO’s machine, production solutions, and our local agent was also very supportive with providing our client with current market insights.

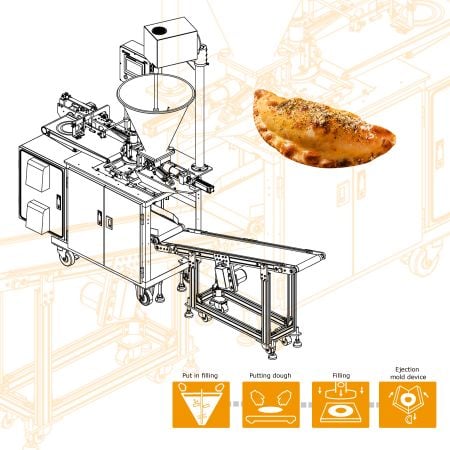

ANKO has found there is an increasing demand for Empanadas in the World marketplace. ANKO’s research has determined that this phenomenon not only exists in Spain and Latin American countries, but also in the USA, Canada, Australia, and the Philippines. And as a result, there is a great demand for automated Empanada machines. ANKO has been approached by many companies and different clients seeking a machine that can process high fat content dough such as puff pastry in order to make Empanadas. Currently, ANKO’s HLT-700 Multipurpose Filling and Forming Machine can produce Spanish style Empanadas with the capacity of over a thousand pieces of products per hour using a variety of forming molds. ANKO’s new EMP-900 Empanada Making Machine is our latest design for making Empanadas with high fat content pastry dough. ANKO’s team has devoted much time researching and developing our Semi-automated Clamping Mold Device, and it was tested using ANKO’s client’s recipe from the USA. This machine has successfully produced Empanadas that can be either baked or deep-fried and fulfilled ANKO’s client product specifications.

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum business in 2019. Initially they purchased equipment from a supplier in China, but the equipment was not as user friendly and required multiple employees to operate. Additionally, they encountered many difficulties and problems during their manufacturing processes. Fortunately, this very same client found ANKO. ANKO is a company that is dedicated to Quality and Productivity while offering customized production solutions for various food products and catering to each of our client’s unique requirements. This client purchased ANKO’s HLT-700XL and EA-100KA for producing dumplings and Xiaolong soup dumplings. The company supplies many schools with dumplings, and they are also working with many central kitchens. With ANKO’s equipment this client was able to establish their own brand since have enjoyed great success.

An ANKO client operates a baking factory in the Netherlands and exports their baked goods to various European countries, including the UK, France, Germany, and Luxembourg. Recently, this client ventured into the production of Chinese Dim Sum and learned about ANKO through local food industry contacts. Due to our excellent reputation, professional expertise and quality service in the industry, we successfully created an automated Har Gow production line for making high-quality Har Gow that met the client’s expectations.

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands. For that reason, automation is what they need to boost capacity and profits.

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors and got great comments on some travel websites. The calzone, both its recipe and ingredients, is handmade by their chef. As spending holidays in the hotel, tourists can buy a portable calzone at a concession stand and enjoy it as leisurely walking around. Due to the widespread reputation of the dish, they decided to buy a machine to meet the growing demand or the future launch of new menu in their restaurants. Then, the gourmet calzones could be produced in their central kitchen and distributed to each restaurant, which not only maintains product quality, but also cuts the labor cost.

The client runs an eatery next to a school. Two people in total have to be in charge of all works. Due to the fact that more and more people patronized the eatery, the labor shortage prompted him to develop machine production. However, high productivity was not his priority so that he ordered a set of HLT-660 series, which is within budget and enough to achieve his hourly capacity around 5000 pieces. After purchasing the machine, they prepare ingredients in the morning and then arrange production around noon, cooking after taking an order, which can satisfy a large demand during peak hours. (Note: HLT-660 series is no longer available. Please contact us for the updated HLT-700 series.)

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy recipes to catch customer's heart. With the increasing popularity of dim sum, he began running a food factory. As seeking food equipment, he knew that ANKO has years of experience in the dim sum making machinery and provides customization in accordance with individual needs and factory planning. Therefore, he decided to cooperate with ANKO.

To increase capacity and standardize products are the main issues that drive food manufacturers and restaurant owners, including this client, to switch from manual to automatic production. The dumplings served in the company's restaurant chains were made by hand in its own central kitchen. Consumers really liked the handmade dumplings, but 'sold out" was the most important issue with which the company had to deal. Moreover, the size, weight, and taste of handmade dumplings might vary from batch to batch. Using a dumpling maker can both improve capacity and achieve standardization. Therefore, he chose us as the solution provider for the automatic production of dumplings. He also wanted to serve deep-fried dumplings and steamed dumplings to satisfy customers' appetite after increasing capacity.

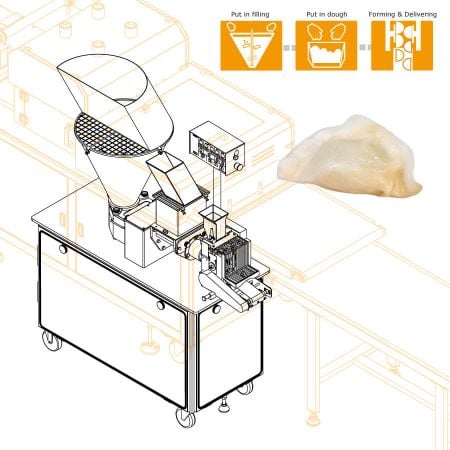

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape. Either customers have to give up having handmade pleats and delicate patterns or they stay in manual production. Dumpling machine has been ANKO's bestseller. We have received many inquiries about dumpling shapes. "Do you have other more natural patterns?", "Do you have pinching patterns?", "Do you have other pinching patterns?", "Why is the machine-made dumplings not mouth-watering?" and so on. To response these demands, we started a series of development processes.