Driving Food Innovation with Dual Solutions: ANKO Helps Australian Client Expand into Diverse Markets

The client operates a central kitchen and restaurant chain in Australia, popular with both locals and tourists. As sales grew and manual production reached its limits, they adopted ANKO’s HLT-700U Multipurpose Filling and Forming Machine to improve efficiency. To meet demand for new flavors and healthier options, the client worked with ANKO to develop custom molds and gluten-free dumplings. Leveraging ANKO’s recipe database and R&D expertise, we ensured stable production, accelerated the product launch, and reduced development costs, helping the client expand their product line and differentiate in the market.

Dumpling

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. ANKO Custom Artisan Mold: Create Plump Steamed Dumplings That Catch the Eye and Delight the Taste

The client originally used a single-sided mold to produce pan-fried dumplings, resulting in dumplings that were only full on one side. With Gen Z consumers seeking new flavors and experiences, the client decided to develop a completely new steamed dumpling product and turned to ANKO for a custom Artisan mold automated production solution.

The new steamed dumplings were designed to be 8.5 cm long and approximately 28 g in weight. Our team first created a 3D mold design for testing and confirmed optimal forming results. The mold was then manufactured from stainless steel using CNC equipment and quickly delivered to the client’s factory. We assisted with installation and trial production, successfully producing dumplings with a fully plump shape and sealed edges.

Additionally, ANKO supported frozen product testing. Using anti-freeze dumpling wrappers, the steamed dumplings maintained their shape, texture, and integrity even after freezing. This solution enabled the client to expand into the frozen food market, improve product consistency, and accelerate the launch of new products.

Solution 2. New Opportunity in Australia's Gluten-Free Market: ANKO Supports Development of High-Quality Dumplings

The client highlighted the growing potential of the gluten-free food market in Australia. While early offerings focused on bread, snacks, cookies, and pasta, recent years have seen expansion into frozen foods, prompting the client to develop gluten-free dumplings. They initially planned to test a dough made from glutinous rice flour mixed with regular rice flour. Before production, ANKO advised that using glutinous rice flour would result in highly sticky dough, which could cause instability during machine production and lead to cracked dumplings.

During testing, the client’s chosen dough indeed proved too sticky and lacked extensibility, confirming ANKO’s prediction. To resolve this, ANKO suggested replacing glutinous rice flour with a mix of regular rice flour and tapioca starch, which reduced stickiness, improved dough elasticity, and allowed stable machine production. The final gluten-free dumplings maintained their shape and elasticity even after freezing and reheating. Taste tests showed the dumplings were chewy, moist, and tender, fully satisfying the client’s quality expectations.

ANKO assisted the client in developing gluten-free dumplings, from adjusting the dough recipe with regular rice flour and tapioca starch to automated machine production. The dumpling wrappers became less sticky and more elastic, maintaining their shape after boiling, meeting the client’s expectations for both texture and health-conscious quality.

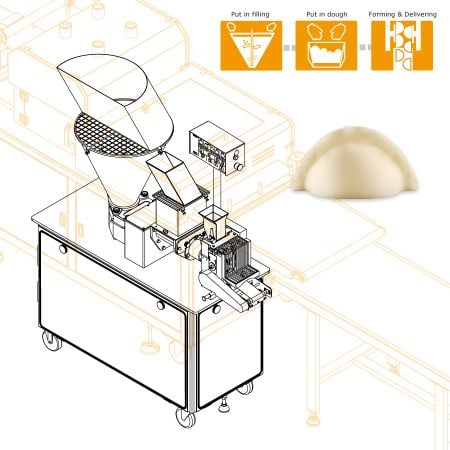

Food Equipment Introduction

- Load the hopper with premade dough

- Load the hopper with premixed filling

- The machine automatically makes Dumplings

An Industry-Leading Food Lab: Consultant-Led Process Accelerates New Dumpling Launch

ANKO features a fully equipped food research lab dedicated to supporting clients in new product development. In this gluten-free dumpling case, selecting the right flours and coordinating with machine production were key factors. To achieve the ideal dumpling wrapper texture, ANKO utilized a texture analyzer for precise testing and conducted multiple comparisons between conventional and gluten-free dough formulations. After finalizing the recipe, dumplings were cooked for on-site client tasting, with our food innovation expert ready to provide immediate adjustments if needed. This consultant-led R&D process ensures the production of high-quality dumplings that meet client expectations.

- Solution Proposal

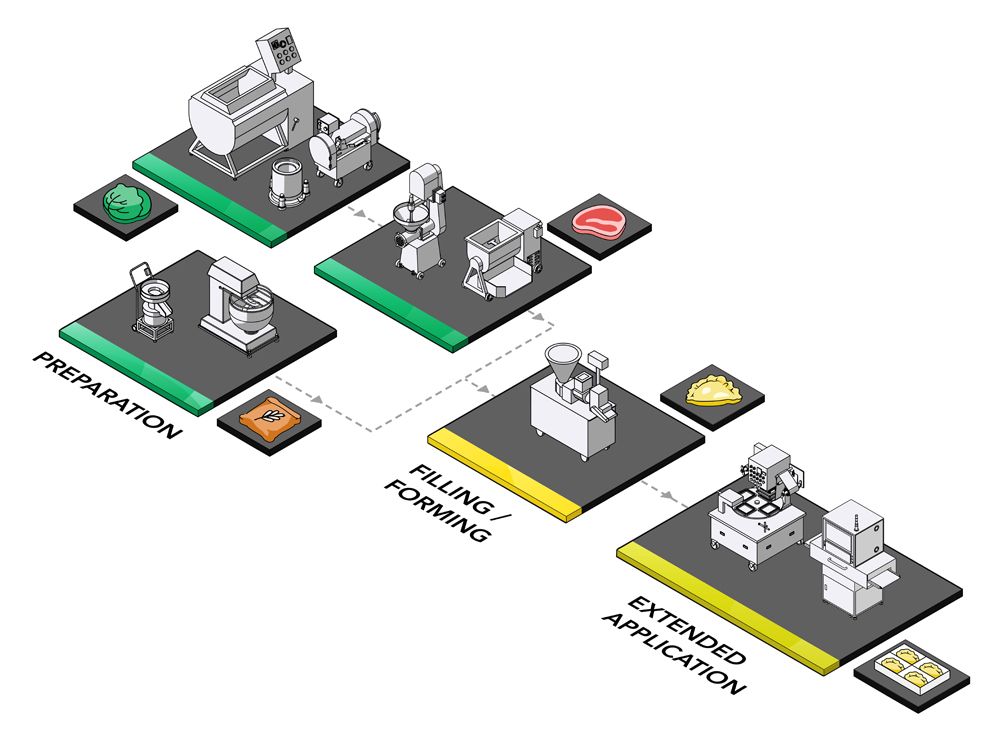

From Cutting to Packaging — A Complete Automated Dumpling Production Solution!

In addition to our flagship HLT-700U Multipurpose Filling & Forming Machine, ANKO can integrate front-, mid- and back-end equipment to deliver a one-stop dumpling production line tailored to your needs. Line options include vegetable cutters, meat grinders, dough mixers, dumpling forming machines, and downstream packaging systems. For retail-ready products, we also integrate blast freezers, X-ray inspection, and other food-safety equipment to ensure consistent quality.

A complete automated line not only boosts production efficiency but also reduces labor requirements and operational complexity, allowing customers to focus on product development and market expansion. For more details about this solution, click Learn More or submit the inquiry form below.

- Machines

-

HLT-700U

ANKO’s HLT-700U Multipurpose Filling and Forming Machine is engineered for high-efficiency, stable dumpling production. With a fully optimized mechanical design, it preserves the natural texture of fillings, allowing smooth forming even with large-chunk, high-fiber, or drier vegetable mixtures.

The machine supports a wide variety of mold options—from natural pleats and wave patterns to cherry blossom, heart-shaped, and animal designs—and also offers full customization. It accommodates product weights ranging from 13 to 100 g, enabling manufacturers to expand into diverse product lines.

In production, the HLT-700U can make up to 12,000 dumplings per hour and requires only one operator to maintain steady output once running, making it ideal for food factories pursuing efficiency and consistent quality. The system is also equipped with IoT connectivity for remote operation monitoring and predictive maintenance, helping prevent unexpected downtime and ensuring optimal production management.

- Country

Australia

Australia Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Australia with advanced automated food production technology for making Dumplings, Har Gow, and Wonton. We also offer integrated solutions for popular foods such as Empanadas, Spring Rolls, Dim Sum, Samosas, Arancini, Momo, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Due to its active immigration policies, Australia has become one of the top ten immigrant destinations in the world. The diverse immigrant population has created a rich culinary culture. Beyond Western cuisine, Chinese food has gained increasing popularity, with “dumplings” holding a special place as a taste of home for the Chinese community. Many Chinese immigrants even establish dumpling factories locally to ensure freshness and authentic flavors.

Classic dumpling fillings include pork with Chinese chives and shrimp, while beef with cabbage, pork with shiitake mushrooms, as well as various seafood or vegetarian options (such as cabbage with tofu) each have their loyal consumer base. With rising health awareness, “gluten-free dumplings” have also appeared on the market, catering to those sensitive to gluten or seeking healthier options.

Mainstream supermarkets such as Woolworths, Coles, and Aldi, along with major Asian grocery stores, carry locally branded frozen dumplings. Due to strong competition, brands continue to launch innovative flavors, including spicy chicken, ginger shrimp, teriyaki beef, and gluten-free vegetable dumplings made with rice wrappers. Dumplings can be cooked in various ways—boiled, steamed, pan-fried, or deep-fried—making them a convenient choice for home meals. This versatility and variety have secured dumplings a valued place in Australia’s diverse food culture.- Handmade Recipe

-

Food Ingredient

Dough: Flour/Water, Filling: Ground pork/Chinese chives/Green onion/Salt/White pepper/Rice wine/Soy sauce/ Sesame oil

Dough Preparation

(1) Mix flour and water, then knead by hand into a dough. (2) Knead until the dough surface is smooth, place it in a container, cover with a damp cloth, and let rest for 2 hours. (3) Lightly dust the work surface with flour, knead the dough again for 3 to 5 minutes, then let it rest for another 30 minutes.

Filling Preparation

(1) Place the ground pork in a bowl with salt, white pepper, rice wine, soy sauce, and sesame oil. Stir in one direction with chopsticks until the meat becomes sticky. (2) Finely chop the Chinese chives and green onions, then mix into the pork. Combine well and refrigerate for 30 minutes.

Assembly

(1) Roll out the dough and flatten it, then use a cup to cut out round wrappers. (2) Place a small amount of water along the edge of the wrapper, add the filling in the center, fold the wrapper in half, and pinch the edges tightly to seal the dumpling.

- Downloads

English

English