Multiple Fillings, One Solution! ANKO Helps Turkish Client Build an Automated Spring Roll Production Line

The client, a well-known Turkish brand with over 60 years of experience in Turkish and Middle Eastern desserts, serves markets in Turkey, the UAE, Russia, Germany, and France. To expand their product line, they adopted food machinery with ANKO’s Turkish agent’s support, achieving strong market results. Impressed by ANKO’s high-capacity SR-27 Spring Roll Machine, they arranged a trial at ANKO’s Taiwan headquarters. Satisfied with the process, they ordered two machines. Three months later, ANKO delivered and provided on-site training, helping the client successfully launch an automated spring roll production line and enhance market competitiveness.

Spring Roll

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Overcoming Recipe Challenges: ANKO Helps Client Successfully Implement Automated Cheese-Filled Spring Roll Production

When the client first visited Taiwan for an SR-27 Spring Roll Machine trial, ANKO prepared a cheese filling close to their original recipe. The trial process went smoothly, and the client decided to purchase the machine on the spot. However, after the machine arrived at the client’s factory, they informed us that they had optimized the filling recipe internally, with different ratios and ingredients compared to the trial in Taiwan. The new filling blended two types of cheese with a small amount of spinach and seasoning, but during mixing it proved too sticky for smooth production. With the professional guidance of ANKO’s team and the local agent, we implemented… (Contact ANKO now for more information).

Ultimately, the cheese filling was successfully processed with the SR-27 Spring Roll Machine, delivering a consistent weight of 45 grams per roll. Unlike the usual cooking method, the spring rolls were baked instead, resulting in less oil but still a crispy exterior—earning high praise from the client.

With ANKO’s guidance, the cheese filling was ultimately made suitable for production with the spring roll machine

After unrolling the wrapped spring roll, it was found that the cheese filling was securely enclosed inside

Solution 2. Efficient Spring Roll Production Line: Achieve Multi-Product Automation and Stable Mass Production with Ease

When introducing a new product — spring rolls — the client’s top priority was automation. Over the years, they had successfully utilized food machinery for production. With labor costs in Turkey rising over 40% in recent years and their brand holding strong recognition and market share in the Middle East, high-efficiency production became a core requirement. For the client, investing in a spring roll machine capable of producing multiple products meant higher initial costs but significant long-term returns.

Beyond cheese spring rolls, the client’s second designated product was beef spring rolls, which hold a solid market share. The filling, made of stir-fried beef, bulgur, and seasonings, was well suited for production with the SR-27 Spring Roll Machine. The machine successfully produced beef spring rolls that, after frying, met the client’s appearance and taste standards. ANKO’s team also provided thorough guidance on machine maintenance and common operational issues to ensure the client could smoothly and consistently produce multiple products using the SR-27.

The SR-27 Spring Roll Machine produces consistently well-formed spring rolls, with customers opting for manual packaging. The spring rolls are then baked, resulting in a product with a perfect appearance and richly filled cheese stuffing. ANKO’s Taiwan headquarters, as well as our branches in the U.S. and the Netherlands, offer trial machine services — schedule for a machine trial with us now!

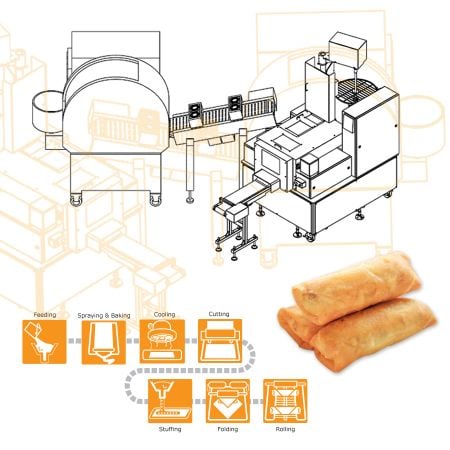

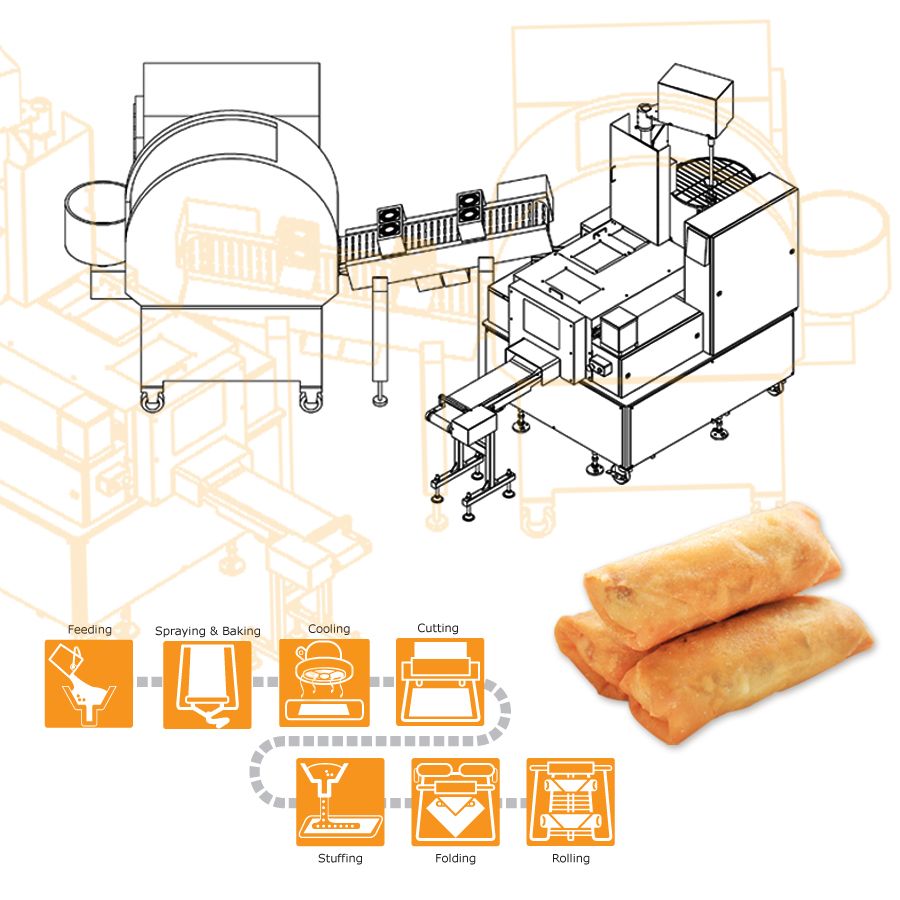

Food Equipment Introduction

- Load the hoppers separately with batter and filling ingredients

- The heating drum cooks the Spring Roll wrapper

- Spring Roll wrappers are cooled

- Wrappers are divided into specific sizes

- Filling

- Folding

- Forming

- Rolling into final product

Perfect Filling Formation for All Ingredients — SR-27 Spring Roll Production Solution

The SR-27 Spring Roll Machine delivers consistent, high-quality spring rolls with versatile filling capabilities. Its advanced filling system handles a wide range of fillings, including pure vegetables such as cabbage, bean sprouts, and mixed vegetables, as well as uncooked fillings—without over-compressing—preserving freshness and texture. It can process root vegetables like sweet potatoes by shredding them and mixing with other fillings or glass noodles, keeping natural chunkiness. The SR-27 also produces shrimp paste spring rolls by blending shrimp with starch, lard, water, and seasonings. The machine preserves shrimp chunks and automatically forms spring rolls with a perfect shape and appearance, supporting efficient, large-scale production.

- Solution Proposal

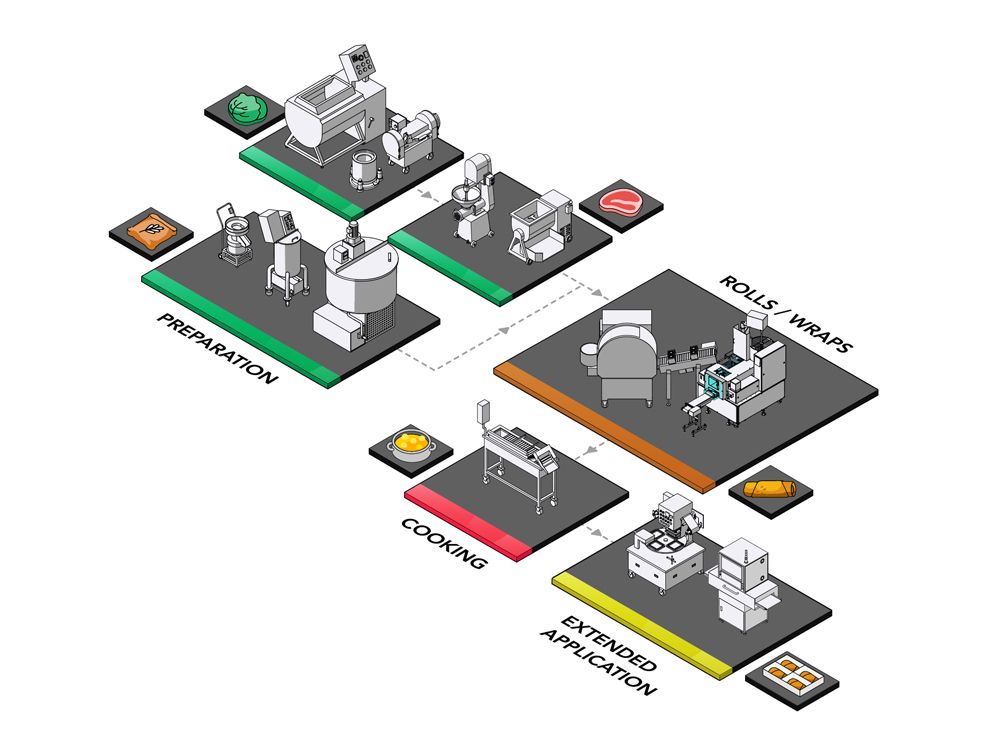

Spring Roll Automation All-in-One! Industry-Leading One-Stop Solution

To achieve fully automated spring roll production, batter preparation can be equipped with a batter mixer and batter storage tank, while filling preparation can use a vegetable cutter and meat grinder. The core equipment for spring roll production is the forming machine. Depending on needs, additional equipment such as a fryer, IQF/freezer, packaging machine, weighing machine, or X-ray inspection system can be integrated to help customers achieve stable mass production.

ANKO offers complete production solutions for the front, middle, and final stages of production. We can also design customized production lines, optimize workflow, and develop new products. By integrating robotic arms and conveyor tracking with intelligent automation technology, ANKO helps customers achieve maximum production efficiency and quality with minimal manpower. For more details about this solution, click Learn More or fill out the inquiry form below.

- Machines

-

SR-27

The SR-27 Spring Roll Machine features a newly design that significantly enhances production stability and extends machine lifespan. With an output capacity of up to 2,700 spring rolls per hour, it simulates the traditional handmade wrapping method and completes one roll in just 1.4 seconds—reducing labor requirements while maintaining consistent product quality.

The machine supports a wide range of fillings, including vegetable-only, meat-and-vegetable mixtures, and even raw, uncooked fillings. Its innovative filling system prevents over-compression, preserving the crisp texture of vegetables and the integrity of the stuffing. Currently, the SR-27 can produce spring rolls in lengths of 7.3 cm, 8.5 cm, and 10 cm, with weights ranging from 22 g to 50 g. Custom sizes can also be developed upon request.

All food-contact parts are designed for low-pressure water cleaning, speeding up daily sanitation and improving operational efficiency, making the SR-27 the ideal equipment choice for large-scale spring roll manufacturers.

- Country

Turkey

Turkey Ethnic Food Machine And Food Processing Equipment Solutions

Our food equipment solutions for clients from over 114 countries. You can click on the following categories to view cases. Each case shows how ANKO conducts food machine solutions - from the beginning of ingredient preparation, machine design and manufacture, troubleshooting and after service.

- Category

- Food Culture

In Turkey, Börek is often referred to as a “Turkish spring roll” or a “Turkish pastry,” and it comes in many variations. It can be made in styles similar to Chinese spring rolls, cigar rolls, or layered pies. Common traditional fillings include spinach and cheese, potato, and minced meat. Typically, the filling is wrapped in triangular dough and then either deep-fried or baked. Börek is a popular snack for families, gatherings, and festive occasions, and it is especially common on iftar tables during Ramadan, becoming a dish shared among friends and relatives.

In Turkish supermarkets such as Migros, CarrefourSA, and Şok, spring rolls are a popular item in the frozen food section, with cheese filling being the top seller. For meat lovers, well-known brands like Pınar and SuperFresh offer potato-and-meat-filled varieties to meet diverse preferences. In bakeries, freshly made spring rolls are a favorite choice for office workers, serving as a convenient and delicious breakfast option.

With Turkish migration spreading worldwide, the presence of Turkish spring rolls has crossed borders. In countries with large Turkish communities, such as Germany, Austria, and the Netherlands, Turkish spring rolls have become part of everyday life. Local Turkish bakeries, cafés, and restaurants not only offer classic cheese-filled versions but also adapt the recipe to suit local tastes. In Middle Eastern countries, where culinary traditions are similar, Turkish spring rolls are also widely enjoyed, appearing frequently in bakeries and restaurants—though names and fillings vary by region, each developing its own distinctive style.- Handmade Recipe

-

Food Ingredient

Pastry: Yufka, Filling: Feta cheese or Turkish white cheese/Mozzarella cheese/Fresh herbs/Lemon zest/Salt/Pepper

How to make

(1) Place all filling ingredients into a container and mix evenly. (2) Take a sheet of Yufka pastry and place the cheese filling on it. (3) Fold one corner of the pastry over the filling, then fold in the two sides, roll up tightly, and seal the edge with a little water. (4) Deep-fry the spring rolls over medium-high heat for about 5 minutes until golden brown and ready to serve.

- Downloads

English

English