Upgrading Dough, Filling, and Texture: ANKO Drives Automated Bun Production in the Netherlands

The client, a Chinese entrepreneur who moved to the Netherlands, started a restaurant specializing in authentic dumplings, famous for thin wrappers and generous fillings appealing to both the local Chinese community and Dutch customers. As the restaurant grew and expansion plans emerged, the client experimented with buns, producing them manually to test market demand. Positive feedback encouraged larger-scale production. Facing increasing orders and limited manpower, the client leveraged their experience with ANKO’s HLT-700XL machine and introduced the SD-97W Automatic Encrusting and Forming Machine, efficiently increasing output, maintaining consistent quality, and offering a wider variety of products for in-store dining and retail.

Char Siu Bao / Meat Bun

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. ANKO Expert Guidance: From Training to Automated Mass Production of Char Siu Bao

After purchasing the SD-97W Automatic Encrusting and Forming Machine, the client received on-site guidance from ANKO experts for machine operation and production training. To maximize teaching efficiency, the client had pre-shared their handmade Char Siu bao process and recipe ratios and prepared all production materials in advance. Upon arrival, ANKO consultants immediately conducted operational training.

Since the machine was pre-configured according to the client’s requirements, automated Char Siu bao production could start right away. During the first steaming test, the baos were well-formed, but the cracks on top were too large. ANKO experts analyzed the recipe, steaming time, and production parameters, identifying the client’s flour type as the main cause of the cracking......(Contact ANKO for more information)

Under ANKO’s professional guidance, the client successfully achieved automated mass production of Char Siu bao with minimal cracking, fluffy texture, and authentic flavor—preserving the classic taste while realizing high-efficiency production.

Solution 2. How to Master Dough-to-Filling Ratio? Insights and Success in Meat Bun Production

Meat Buns are also among the client’s best-selling products. Before the machine trial, the client specifically requested a 1:1 dough-to-filling ratio to replicate the handmade texture. Based on years of experience, ANKO’s consultant advised that this ratio could cause cracking after steaming. Indeed, during the first trial run, while the SD-97W Automatic Encrusting and Forming Machine successfully shaped the Meat Buns, the steamed products cracked and filling leaked out, compromising appearance and quality.

To resolve the issue, ANKO’s consultant optimized the recipe and production parameters by adjusting the dough weight to 50 g, the filling to 30 g, and fine-tuning the SD-97W settings. After the adjustment, the steamed Meat Buns came out with smooth, intact exteriors, no cracking, and filling firmly enclosed. The texture was chewy and well-balanced, fully meeting the client’s requirements for high-quality mass production and sales expectations.

In this case, both the Char Siu Bao and Meat Buns were produced using deep-pattern molds. The SD-97W also offers shallow-pattern, plain, and other specialized molds for a variety of filled products. In addition to our Taiwan headquarters, ANKO has branch offices in the U.S. and the Netherlands, providing nearby customers with timely and professional support while expanding their markets.

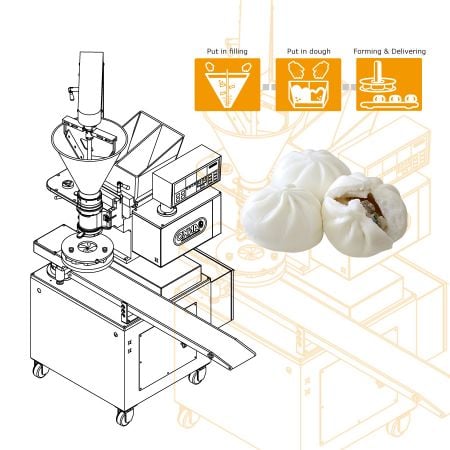

Food Equipment Introduction

- Load the hopper with dough

- Load the hopper with filling

- The machine automatically makes Buns

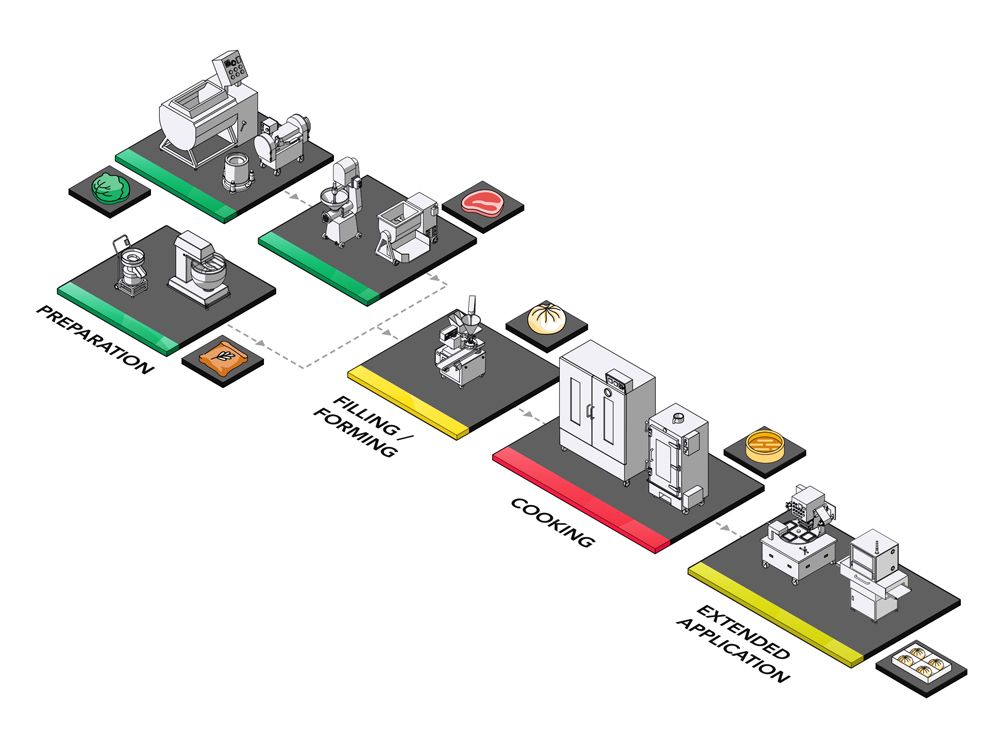

Flexible SD-97W Integration: Expand Product Lines and Enhance Automation

In this case, the client only used the SD-97W for production, but the SD-97W can be integrated with other machines to increase product variety while enhancing automation. For example, when paired with an Automatic Stamping and Aligning Machine, it can produce Mooncakes, Maamouls, Red Tortoise Cakes, and more. When combined with an Automatic Aligning Machine, products such as Buns, Pineapple Cakes, and Cookies can be automatically arranged on trays and sent to steamers or ovens tray by tray, improving production efficiency and optimizing labor utilization.

For products that require round shaping, such as Indian dessert Rasgulla, Filled Glutinous Rice Balls, or Energy Balls, the RC-180 Automatic Rounding Conveyor can be used, saving both labor and production time. For fried products, items formed by the SD-97W can be directly sent to a Conveyor Fryer, producing foods such as Croquettes, Kibbehs, and Coxinha. Machine configurations can be tailored according to the client’s needs and product characteristics, helping to address production challenges efficiently.

- Solution Proposal

Integrated Bun Production Solution: SD-97 Drives Your Production Line Upgrade!

The global bun market is projected to grow at 7.6% CAGR, reaching $2.77 billion by 2033. ANKO’s SD-97 Automatic Encrusting and Forming Machine enables consistent production of Char Siu Bao, Meat Bun, Custard Bun, Vegetable Bun, Bean Paste Bun, and Crystal Dumplings.

We also offer supporting equipment—dough mixers, vegetable cutters, meat grinders, steamers, packaging machines—and can integrate existing devices like freezers, weighing machines, and environmental monitors to create a fully automated Bun production solution.

Whether you want to expand capacity, optimize processes, or improve product consistency, ANKO can design the ideal setup for your needs. Click Learn More or submit the inquiry form to get expert guidance.

- Machines

-

SD-97W

The SD-97W Automatic Encrusting and Forming Machine produces 1,000–4,000 pieces per hour in a compact footprint, making it ideal for various filled foods. Using compatible accessories, it can quickly make Vegetable Buns, Mochi, Cookies, Meatballs, Energy Balls, and more. It works with regular dough, glutinous rice dough, or dough mixed with grains, and handles meat, vegetable, fruit, or bean paste fillings easily, with adjustable dough-to-filling ratios. Equipped with IoT monitoring, operators can track machine status and component usage via mobile devices, schedule maintenance, and prevent downtime, ensuring maximum efficiency during peak production periods.

- Country

Netherlands

Netherlands Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in the Netherlands with advanced automated food production technology for making Dumplings, Xiao Long Bao, Har Gow, and Roti. We also offer integrated solutions for popular foods such as Empanadas, Loempia (Spring Rolls), Kibbeh, Samosas, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.To better serve clients in Europe, ANKO proudly established its Netherlands branch, ANKO FOOD TECH B.V., in July 2025. Located in Rotterdam, our 1,500-square-meter Food Machinery Experience Center offers hands-on demonstrations and local consultation services, providing timely and tailored support to food manufacturers in the region.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

In the Netherlands, Char Siu Bao (BBQ Pork Buns) and Pork/Meat Buns are not traditional local dishes. In major cities such as Amsterdam, Rotterdam, and The Hague, there are sizable Chinatowns and Cantonese dim sum restaurants, where Char Siu Bao is often one of the most popular items on the table. Locals enjoy sharing steaming baskets of Char Siu Bao and other dim sum with family or friends during gatherings, making them increasingly familiar and beloved as Asian snacks in the Netherlands. In terms of taste, the Dutch prefer Char Siu Bao with slightly sweeter, richly sauced pork filling, while Pork Buns are favored with savory but not overpowering flavors, juicy meat, and a non-greasy texture.

Due to historical colonial ties with Indonesia, the Netherlands has a strong connection with Indonesian culture, and many Indonesian-Chinese communities have brought their bun traditions with them. In mainstream Dutch supermarkets such as Albert Heijn and Jumbo, you can find “Bapao / Bakpao,” Indonesian-style steamed buns, typically filled with chicken, but also available with pork, beef, or vegetarian options. Many office workers use these buns as a convenient lunch, heating them in the microwave for a few minutes. At Asian supermarket chains like Amazing Oriental, a variety of frozen Char Siu Bao and Pork Buns are available, often attracting families. These buns are a quick and versatile choice, suitable for breakfast, lunch, or a late-night snack.- Handmade Recipe

-

Food Ingredient

Dough: Cake flour/Baking powder/Sugar/Yeast/Water/Oil, Filling: Char siu/Oyster sauce/Sugar/Water/Potato starch/Onion

Dough Preparation

(1) Mix the yeast with water and let it sit. (2) In a separate bowl, combine cake flour and sugar, then gradually add the yeast water and mix into a dough. (3) Add oil and knead for 3–5 minutes, then let the dough rest for 30 minutes. (4) After resting, add baking powder and knead until evenly incorporated.

Filling Preparation

(1) Dice the onions and Char Siu. (2) Heat oil in a pan, sauté the onions until soft, then add the Char Siu. (3) Add oyster sauce, water, sugar, and potato starch, stirring to combine. Cook until the mixture thickens into a semi-solid filling, then let it cool.

Product assembly

(1) Divide the dough into equal portions and roll each into a thin round sheet. (2) Place the filling in the center and pleat the edges to seal the bun. (3) Place the prepared buns on parchment paper in a steamer and steam over high heat for 12 minutes before serving.

[The method for pork buns is similar to Char Siu buns, with only slight differences in both the dough and filling.]

- Downloads

English

English