Automation in Action × New Product Development: ANKO Upgrades Wonton Production for a Singapore Client

The client originally produced Wontons by hand in Singapore. As the brand expanded and demand increased, the client attended the FHA Food & Beverage Exhibition in Singapore to seek automated solutions and visited ANKO’s booth for more information. After evaluation, the client recognized ANKO for its reliable machine quality and professional support, and traveled to Taiwan to test the HWT-400 Automatic Wonton Machine. The trial ran smoothly, with products closely replicating handmade Wontons, leading the client to purchase the first machine. More than a year later, to support capacity expansion and new product development, the client purchased a second Wonton machine from ANKO, successfully expanding the market and supporting long-term brand growth.

Wanton/Wonton

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Wontons Cracking During Production? How the HWT-400 Solves It

After installing the HWT-400 Automatic Wonton Machine at the client’s factory, ANKO provided on-site training and tested two recipes. The first, a yellow dough with pork filling, ran smoothly—producing uniform Wontons weighing 14 to 15 g each, which the client then manually boxed. The second recipe combined pork with shrimp chunks. During the trial, some Wonton bottoms cracked. ANKO engineers reviewed the recipe, machine settings, and filling size, pinpointed the cause, and resolved the issue... (Contact ANKO immediately for more detailed information.)

Post-adjustment, the Wontons were plump and intact. When cooked in soup, the wrappers were thin, semi-transparent, and chewy, with fully filled interiors. The client was very satisfied. ANKO’s training not only ensured smooth production but also helped the client successfully transition from manual to automated Wonton production while learning to operate the machine efficiently.

Solution 2. How Automation Produces New Wonton Products and Expands Markets

More than a year after successfully transitioning to automated production, the client approached ANKO again to purchase another machine, aiming to develop export markets with a new Wonton product. After clarifying the requirements, ANKO recommended using a different clamping mechanism to produce larger Wontons, each weighing 18 g, with thick, resilient wrappers and a filling of fresh shrimp and pork.

The client conducted a remote trial using the HWT-400 Automatic Wonton Machine to produce the shrimp and pork large Wontons. After verifying production status, finished product specifications, and cooking quality, the client confirmed the order. Since the previously purchased Wonton machine required scheduled maintenance, ANKO’s team visited the factory after delivery to assist with large Wonton production and complete the maintenance process.

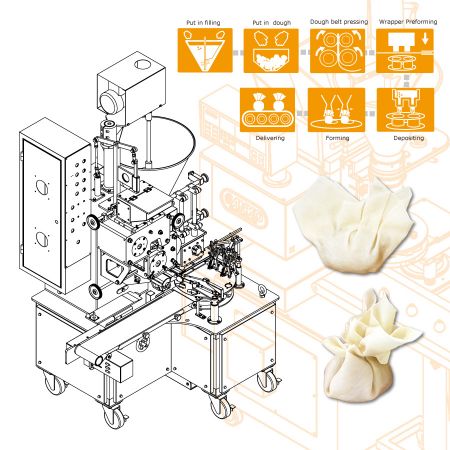

The HWT-400 Automatic Wonton Machine handles wrapper making, cutting, filling, and forming, then pushes finished Wontons onto the conveyor. The entire process requires only one operator, producing 3,000 to 4,200 Wontons per hour—an efficient and reliable production partner for Wonton manufacturers.

Food Equipment Introduction

- Load the hopper with premade dough

- Place premixed filling into the filling hopper

- The machine automatically makes Wantons

HWT-400 Wonton Machine: Flexible Clamping for Diverse Market Needs

The HWT-400 Automatic Wonton Machine features two clamping mechanisms – Flat Clamp and Square Clamp. The Flat Clamp leaves a large portion of the wrapper on top, creating a hand-folded “Bian Shi” appearance, popular among Asian customers. The Square Clamp forms the Wontons into a money bag shape, favored by Western markets. The machine produces Wontons weighing 12 to 17 grams, and ANKO has also supported clients in making larger 22-gram Wontons. Filling portions and final shapes can be adjusted to meet specific production needs.

- Solution Proposal

ANKO Comprehensive Wonton Production Solution: Boosting Efficiency and Market Competitiveness

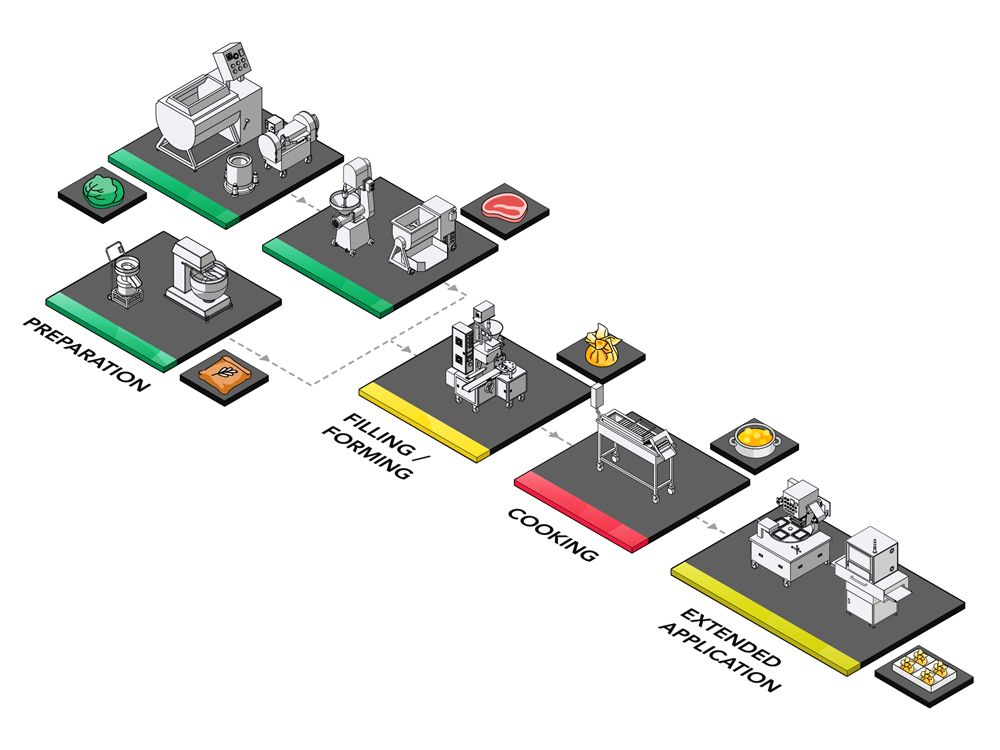

ANKO provides a one-stop Wonton production solution covering pre-processing, forming, and post-processing equipment. Pre-processing includes dough mixers, meat grinders, and vegetable cutters; forming is handled by the HWT-400 Automatic Wonton Machine; and post-processing equipment such as fryers and packaging machines can be flexibly configured based on cooking and packaging requirements. For products entering retail channels, X-ray inspection systems are recommended to prevent foreign objects from reaching consumers, safeguarding product quality and brand reputation.

In addition, ANKO’s Food Lab supports recipe optimization and customized Wonton development, including resilient wrappers, freeze-resistant or boil-stable formulations, and innovative filling options. Backed by over 48 years of experience and a professional R&D team, ANKO helps clients reduce development costs, accelerate product launches, and strengthen market competitiveness. To learn more about our Wonton production solutions or recipe services, click Learn More or submit an inquiry using the form below.

- Machines

-

HWT-400

The ANKO HWT-400 Automatic Wonton Machine produces 3,000 to 4,200 Wontons per hour, completing the entire process—from wrapper making to final shaping—at the push of a button. A specially designed clamping process replicates hand-folding techniques, ensuring the filling is fully enclosed while maintaining both appearance and texture. Wonton spacing and conveyor speed are adjustable to support manual sorting or boxing in downstream operations. Modular pressing rollers allow for quick installation and removal, simplifying daily cleaning and maintenance. Equipped with an IoT monitoring system, the machine records daily production data and alerts operators to potential wear or scheduled maintenance needs, reducing downtime and improving overall production management efficiency.

- Country

Singapore

Singapore Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Singapore with advanced automated food production technology for making Dumplings. We also offer integrated solutions for popular foods such as Curry Puffs, Empanadas, Mochi, Shumai, Meatballs, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

In Singapore, Wontons (Wanton) are one of the most popular street foods, often enjoyed for breakfast or lunch. The most iconic way to eat them is in Wonton Mee, a classic dish that combines springy egg noodles with Wontons, char siu (barbecue pork), and vegetables. It can be easily found at hawker centers or restaurants across the city. Wonton Mee is commonly served in two styles: dry or soup. The dry version tosses noodles, Wontons, and char siu with savory sauces, while the soup version features a clear or flavorful broth, allowing diners to enjoy the dish according to personal preference.

Common fillings for Wontons in Singapore include shrimp, pork, or a mixture of shrimp and ground pork. Some vendors also offer vegetarian or innovative flavors, such as curry or spicy Wontons. For home cooking, major supermarkets like NTUC FairPrice, Sheng Siong, and Cold Storage sell a variety of frozen Wonton brands, including CP, Crystal Jade, Q FRESH, and JINJILI (Chinatown Food). Some brands even provide ready-to-use broth or soup powder, making it easy for consumers to prepare Wonton soup at home. In addition to soup, there are also fried or instant versions of Wontons, offering a wider range of flavors for consumers.- Handmade Recipe

-

Food Ingredient

Dough: Flour/Water/Salt, Filling: Ground Pork/Green Onion/Ginger/Salt/White Pepper/Soy Sauce/Sesame Oil/Broth (or Water)

Dough Preparation

(1) Mix flour and salt, then gradually add water and knead by hand to form a dough. (2) Knead until the dough is smooth and elastic, then place in a container, cover with a damp cloth, and rest for 20 to 30 minutes. (3) Remove the rested dough, sprinkle a small amount of flour on the work surface, and knead repeatedly for 3 to 5 minutes to strengthen the gluten.

Filling Preparation

(1) Place ground pork in a bowl with salt, white pepper, soy sauce, and sesame oil. Mix in one direction with chopsticks or hands until the meat becomes sticky. (2) Gradually add broth (or water) while continuing to mix, allowing the meat to absorb moisture and achieve a tender, juicy texture. (3) Finely chop green onion and ginger, then fold into the meat mixture. (4) Refrigerate the prepared filling for about 30 minutes to stabilize flavor and texture.

Assembly

(1) Roll the dough into thin sheets and cut into squares or diamond-shaped Wonton wrappers. (2) Place an appropriate amount of filling in the center of each wrapper, gently pressing out any air. (3) Fold the wrapper into a triangle and pinch the two side corners to secure, forming a 3D Wonton shape. Wontons are now ready.

- Downloads

English

English