Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

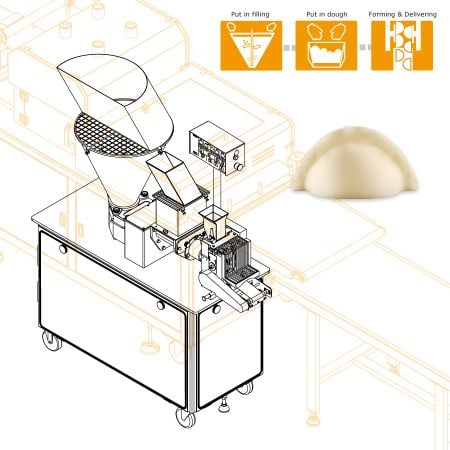

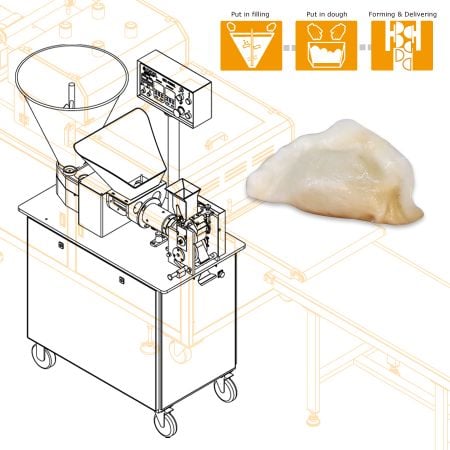

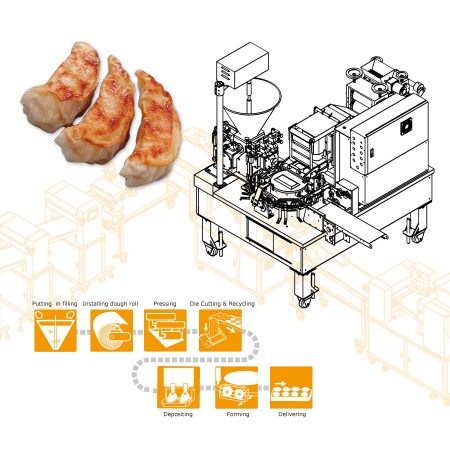

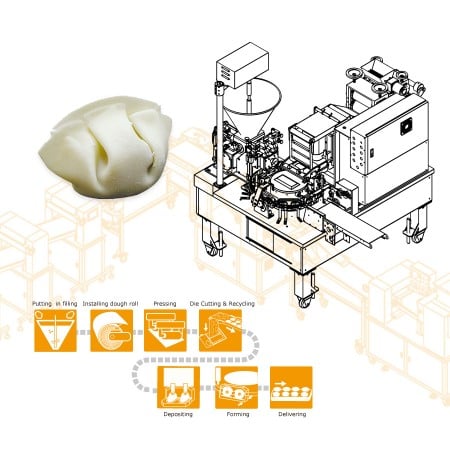

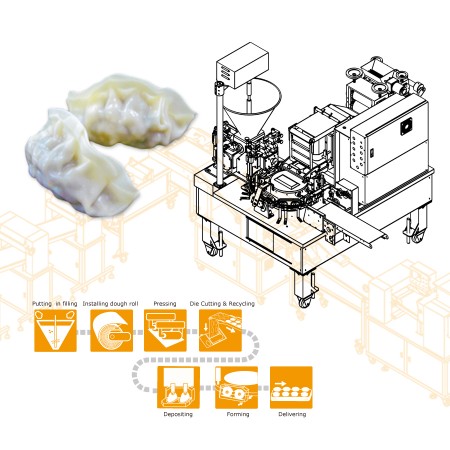

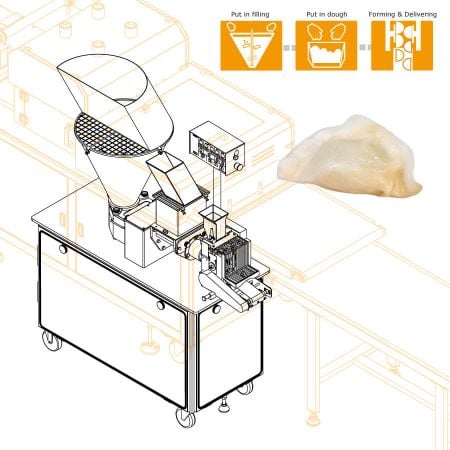

The client operates a central kitchen and restaurant chain in Australia, popular with both locals and tourists. As sales grew and manual production reached its limits, they adopted ANKO’s HLT-700U Multipurpose Filling and Forming Machine to improve efficiency. To meet demand for new flavors and healthier options, the client worked with ANKO to develop custom molds and gluten-free dumplings. Leveraging ANKO’s recipe database and R&D expertise, we ensured stable production, accelerated the product launch, and reduced development costs, helping the client expand their product line and differentiate in the market.

This client is a third-generation Chinese American who inherited his grandfather's wholesale food business in the United States. A few years ago, his company had to adjust to accommodate the changes in the overall marketplace and focused on producing and distributing Chinese cuisines. After thorough market research, the client purchased ANKO's HLT-700U Multipurpose Filling and Forming Machine to make authentic Chinese Dumplings. After nearly a year of market testing, which showed promising sales, the client further invested in the ER-24 Automatic Egg Roll Production Line and AF-589 Conveyor Fryer a year later. ANKO's high-quality and durable food machinery has successfully helped clients excel in authentic Chinese food production and become leaders in the market.

![ANKO Smart Machine – Pioneering The Integration of Internet of Things [IoT] in Automated Food Production](https://cdn.ready-market.com.tw/aa42f2c9/Templates/pic/m/HLT-700U-Dumpling.jpg?v=db51b6c8)

ANKO regards the IoT system as the foundation for new automated production lines when transforming into an intelligent factory influenced by the Industry 4.0 movement. Our new IoT system was officially introduced in December 2022 after more than three years of development working with system integration companies and various feasibility tests. ANKO introduces our IoT system to the HLT-700U Multipurpose Filling and Forming Machine, to satisfy the increasing market demand for various Dumplings and similar food products that our clients request Worldwide. During the development stage, a Taiwanese client used ANKO’s HLT-700U to produce Dumplings and based on their feedback, our engineers continued to improve our IoT system. After multiple user testing and verification, this client was very satisfied with the advantages ANKO’s IoT system provided to their production needs. ANKO is able to assist businesses transition into smart manufacturing, and we are also proud to have achieved new milestones in smart machine innovation and in the food production process.

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum business in 2019. Initially they purchased equipment from a supplier in China, but the equipment was not as user friendly and required multiple employees to operate. Additionally, they encountered many difficulties and problems during their manufacturing processes. Fortunately, this very same client found ANKO. ANKO is a company that is dedicated to Quality and Productivity while offering customized production solutions for various food products and catering to each of our client’s unique requirements. This client purchased ANKO’s HLT-700XL and EA-100KA for producing dumplings and Xiaolong soup dumplings. The company supplies many schools with dumplings, and they are also working with many central kitchens. With ANKO’s equipment this client was able to establish their own brand since have enjoyed great success.

Due to high labor costs and employee management issues, the client, specialized in making Chinese food, started to look for a food processing line for making fried and steamed dumplings. A friend recommended ANKO Food Machine Company to the client. With dumpling making equipment operates automatically, the client is able to increase their production amount with better management. In addition, AFD-888 with CE certificate meets the client's necessary requirement- food safety and hygiene. It is the most important reason that the client chooses ANKO. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

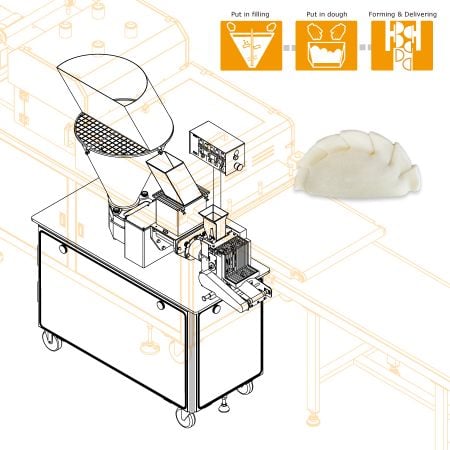

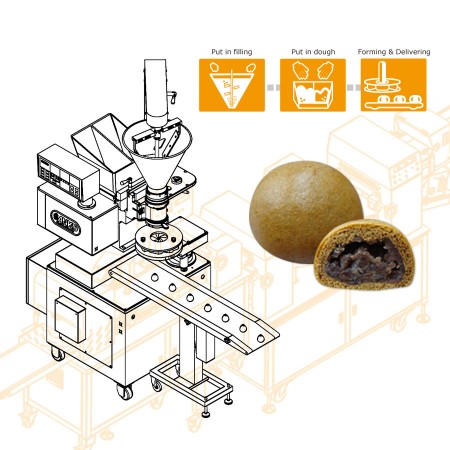

This company owns a bakery, selling various buns and bread. Brown sugar is a common ingredient in Asian cooking, and many people consider it to be healthy food. The client develops a stuffed bun which dough is added brown sugar and which only weighs 12-15g. Since they started selling brown sugar steamed buns, the great popularity has made them hard to handle so many orders. Knowing ANKO is the expert in designing food processing equipment, they contacted us for solutions.

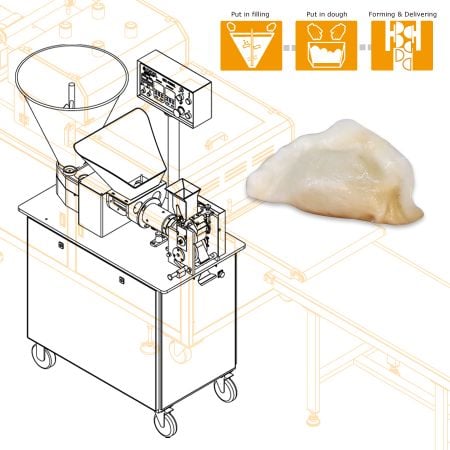

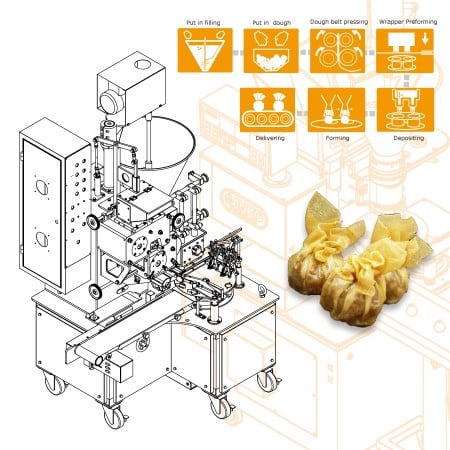

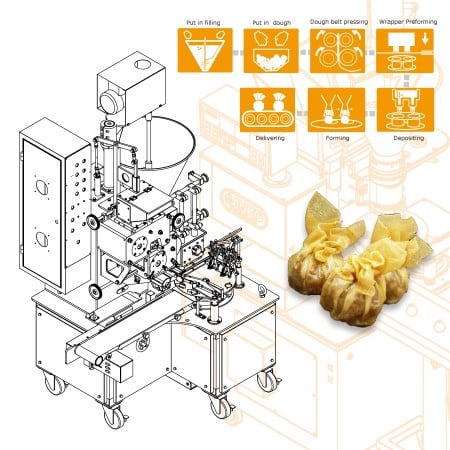

The Canadian frozen food market is facing keen competition. Locals prefer ordering out or taking away food so as to save time. Ready-meal is also a choice for many families. In the client's chain restaurants, wonton soup is one of the most popular combinations. With the growing number of branch stores, they have to prepare more and more pieces of wonton every day. Therefore, they start using ANKO's wonton machine to automatically produce wonton, and then they freeze cooked wonton and deliver to every restaurant, which enable a rapid response to the increasing demand.

The client produces a wide range of products from dairy products, frozen ready meals to bakery. They are also devoted to customizing innovative foods. Various flavors and delicate appearances are superior to other competitors' products. However, the frozen food market changes all the time. How can the company strictly control costs while guaranteeing capacity and quality? The knack is the combination of machine-made and hand-made processes. They do not just sell unchanged products but garnish foods and vary flavors to surprise consumers. The combined processes not only save time and costs, but also turn the impression of uninteresting products made by machines. It is our pleasure that ANKO's machinery was chosen to shape their basic products, which means that our efficient and high quality machinery gains favor with the client.

Vegetarian foods are the client's primary products. The manual production no longer meets the growing demands. For that reason, automation is what they need to boost capacity and profits.

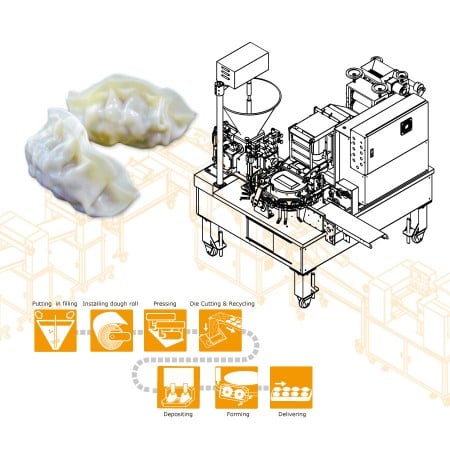

The client, one of our old clients, purchased ANKO's Hargao Forming Machine and Fish Ball Machine. He not only is an OBM of frozen food products but also supply OEM service. In Spanish frozen food market, gyoza was rather new to locals. However, the client was brave expanding an all-new production line on the strength of the well-known brand he created. He hoped gyoza, a dish represents Japanese culture, could be served on the tables in Spain. In order to develop a complete new project, the choice of machine supplier shall be more careful. The client had a pleasant experience of cooperating with us so that he was confident that we were able to plan a whole production line, including machines for preparing ingredients and cooking products such as a steamer, etc. About the gyoza making machine, we recommended him AFD-888, it is with a closing mold device which can produce springier yet firm in taste and more delicate in appearance. The whole project was well prepared and ready to hit the market. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

The client runs an eatery next to a school. Two people in total have to be in charge of all works. Due to the fact that more and more people patronized the eatery, the labor shortage prompted him to develop machine production. However, high productivity was not his priority so that he ordered a set of HLT-660 series, which is within budget and enough to achieve his hourly capacity around 5000 pieces. After purchasing the machine, they prepare ingredients in the morning and then arrange production around noon, cooking after taking an order, which can satisfy a large demand during peak hours. (Note: HLT-660 series is no longer available. Please contact us for the updated HLT-700 series.)

The client began his business from running a dim sum restaurant, introducing the taste of Chinese cuisine to the Dutch and developing a health-oriented menu. With the growth of business, they established a food processing factory. As looking for equipment, they found that ANKO has years of experience in the field of food equipment and customizing machinery on the basis of individual needs and factory space. Therefore, he decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

The growing demand for frozen food and take-out food has led to intense competition in the Spanish frozen market. The client has run restaurants and sold frozen food to many supermarkets. Due to the expansion of the market, they needed a complete productivity solution that allowed new dumpling making machine to work well with their packing line and comply with food hygiene regulations. ANKO, as a solution provider, has many related experiences and the ability to customize machines, so they decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

To increase capacity and standardize products are the main issues that drive food manufacturers and restaurant owners, including this client, to switch from manual to automatic production. The dumplings served in the company's restaurant chains were made by hand in its own central kitchen. Consumers really liked the handmade dumplings, but 'sold out" was the most important issue with which the company had to deal. Moreover, the size, weight, and taste of handmade dumplings might vary from batch to batch. Using a dumpling maker can both improve capacity and achieve standardization. Therefore, he chose us as the solution provider for the automatic production of dumplings. He also wanted to serve deep-fried dumplings and steamed dumplings to satisfy customers' appetite after increasing capacity.

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape. Either customers have to give up having handmade pleats and delicate patterns or they stay in manual production. Dumpling machine has been ANKO's bestseller. We have received many inquiries about dumpling shapes. "Do you have other more natural patterns?", "Do you have pinching patterns?", "Do you have other pinching patterns?", "Why is the machine-made dumplings not mouth-watering?" and so on. To response these demands, we started a series of development processes.