ANKO's Japanese Manju Production Line – Fulfilling Large Purchase Orders for a Japanese Company

This company owns a bakery, selling various buns and bread. Brown sugar is a common ingredient in Asian cooking, and many people consider it to be healthy food. The client develops a stuffed bun which dough is added brown sugar and which only weighs 12-15g. Since they started selling brown sugar steamed buns, the great popularity has made them hard to handle so many orders. Knowing ANKO is the expert in designing food processing equipment, they contacted us for solutions.

Manju (Steamed bun)

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Brown sugar steamed bun skin cracked after steaming.

For the first couple of times, the brown sugar steamed buns were cracked after steamed. ANKO team realized that, and thus they made some changes to solve the problem. There are several solutions, including increasing moisture in dough, lowering the steaming temperature to ...(Please contact us to get more information)

Solution 2. Shutter set design of Japanese manju processing machinery

As a food machinery designer, the timing of clamping and cutting is critical; if the timing isn't right, the food forming process would fail. The shutter set designed by ANKO team is able to make different ethnic foods, including pork buns, manju, mochi, kubba, Arancini, etc. Besides making round-shaped steamed buns, the machine can be fitted two dough containers for delivering two-color foods.

Solution 3. ANKO's Food Experience Worldwide

People like handmade steamed buns or bread because they feel that the texture is better. To make the brown sugar steamed buns taste like 100% handmade, ANKO engineering team tried many different ingredients and made adjustments to the machine before reaching the goals. In the end, the steamed bun tastes like handmade. The client was quite happy with ANKO's services since there was no other food equipment supplier who would like to design, make adjustment and do many food solutions for them.

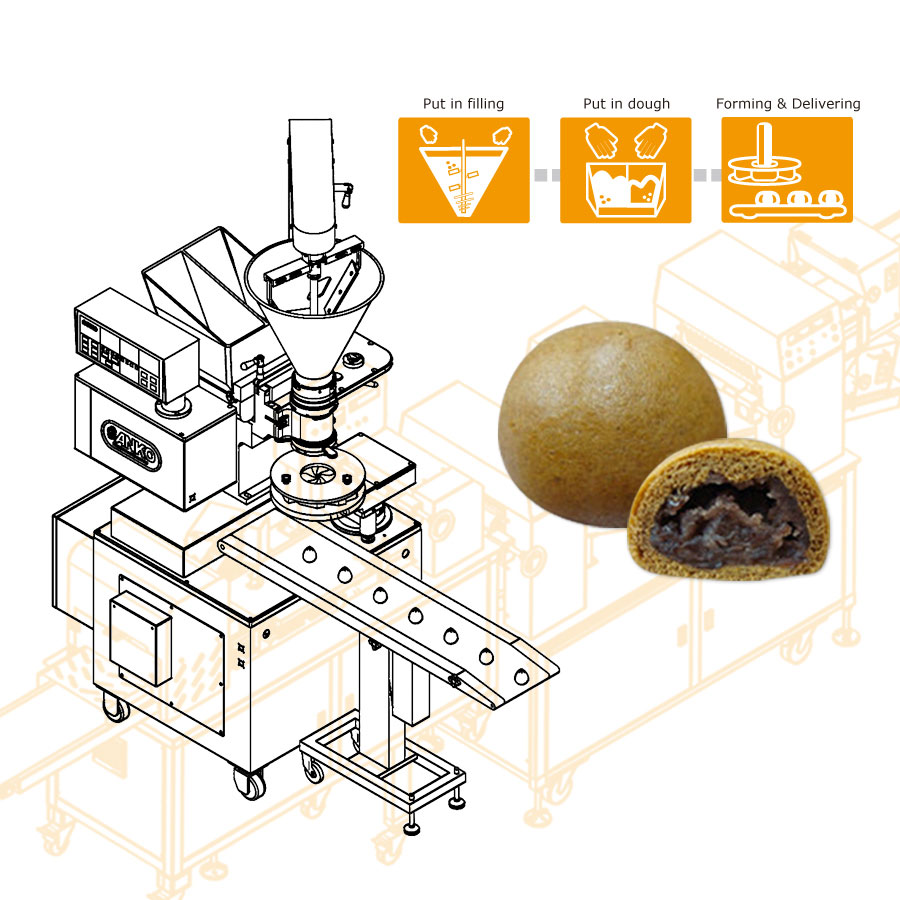

Food Equipment Introduction

- Put steamed bun filling in feeding hopper, let filling propellers mix it well.

- At the same time, put kneaded dough in dough container to start the process.

- Machine extrudes out a dough wrapper with filling inside the roll.

- The designed shutter set will cut and shape the stuffed bun while the conveyor is transferring the completed ones to the next process.

- For the next process, depending on how locals would like, finished products can be fried or steamed.

Fundamental of Design

- The design of automatic encrusting and forming machine is built with great flexibility in changing shapes of foods, fillings and achieving production capacities, client requirements.

- Our clients who purchase this food making equipment will be able to supply dynamic foods to their target market and at the same time slowly adjust the selections to meet market needs.

- Solution Proposal

The Key to Automated Steamed Bun Productions

ANKO did

With ANKO's Automatic Encrusting And Forming Machine, Steamed Buns can be easily produced with different kinds of fillings. There are three types of machine available, SD-97SS, SD-97W and SD-97L. According to your demand, our professional consultant will offer the corresponding machines.

ANKO can help you more

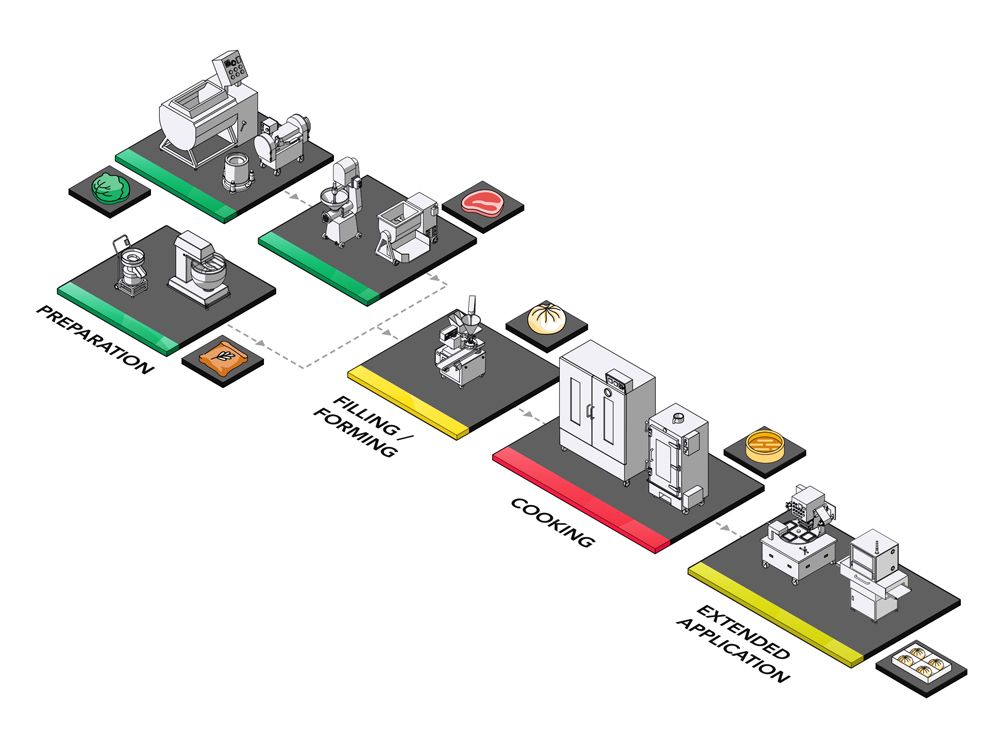

The process of making Steamed Buns is complicated and overloaded. First, proofing equipment is a must, which enables you to proof dough efficiently. Second, the processing equipment for dealing with the fillings are required. Third, an encrusting and forming machine is the key to high-quality Steamed Buns. Last, you can choose a steamer or packaging machine depending on how you sell to consumers. ANKO also offers a Food X-ray Inspection Machine to enhance product safety and quality control.

For more information on ANKO's Steam Bun Production Solution, please click Learn More or fill out the inquiry form below.

- Machines

-

SD-97W Automatic Encrusting and Forming Machine

SD-97W automatic encrusting and forming machine is a multipurpose machine which is able to process various stuffings with different textures. Not only the products with red bean paste, meat stuffing, or sesame paste but also plain products are producible. The foods produced by SD-97W are able to compare with handmade ones. The IoT (Internet of Things) have been installed to ensure that the production can be overseen by managers in real time remotely. All the manufacturing data and the production yield rate is collected daily and analyzed via Big Data to provide you with cost-effective suggestions for making your production line more effective.

ML-15 Planetary Mixers for Large Size Dough

A mixer that is for food industrial usage with a high volume of workload. In addition, its rotating stirrer is changeable. It means you can switch stirrers for stirring various characters of dough, including flat beater, hook, and wire whip.

AS-610 Gas Steamer for Steamed Bun and Bread

AS-610 is a gas steamer for steaming buns. The auto-ignition and temperature control steamer is designed with two different gas heating systems - LPG gas and natural gas. With the evaporator in the steamer, the water is boiled fast. Its auto water-feeding function saves time, too. Overall, AS series bun and bread steamer is effective and functional.

- Video

- Country

Japan

Japan Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Japan with advanced automated food production technology for making Manju, Gyoza and Mochi. We also offer integrated solutions for popular foods such as Dumplings, Xiao Long Baos, Shumai, Hargaos, Soup Dumplings and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Manju is a type of traditional Japanese flour-based pastry. It originated in China, and many believe that Manju was brought to Japan by an envoy; the recipes have changed over the years, and adzuki bean paste is often used instead of meat catering to Monks that preferred a plant-based diet. Manju has become a popular Japanese confection, also known as “wagashi” (和菓子) ; it has many different regional varieties in Japan and it is often sold as special item and souvenirs for travelers. There are many different types and shapes of Manju, the most common is spherical, and it can be made into flower shaped or animal figures. Manju is also a highly prized product sold on one of largest electronic commerce and online retailing sites in Japan. Brown sugar Manju is one of the best-selling flavors; and recently, companies have created fashionable flavors such as truffle, sweet sake, custard, and matcha to attract new and younger consumers.

- Handmade Recipe

-

Food Ingredient

Cake Flour/All purpose flour/Brown sugar/Baking powder/Yeast/Water/Milk/Bean paste/Condensed milk

For dough

(1) Mix cake flour with all purpose flour together and then add brown sugar, baking powder and yeast. (2) Slowly add in water and milk until they start to become dough. (3) Continue kneading and rolling for 10 minutes until dough is elastic. (4) In the end, sprinkle some flour and knead for another 5 minutes. (5) Set aside and rest for more than 20 minutes.

For filling paste

For the filling, you can choose whatever you like, it can be sweet potato, black bean, green bean, or yam. Whatever you pick for filling, slowly cook until soft, add condensed milk when it's soft. Stir and mix until it turns into paste.

Wrapping

(1) Cut dough into small balls and roll them flat using a rolling pin. (2) Grab a small amount of paste and put it in the middle, wrap it up and put them in the steamer for 5 minutes.

- Downloads

English

English