Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

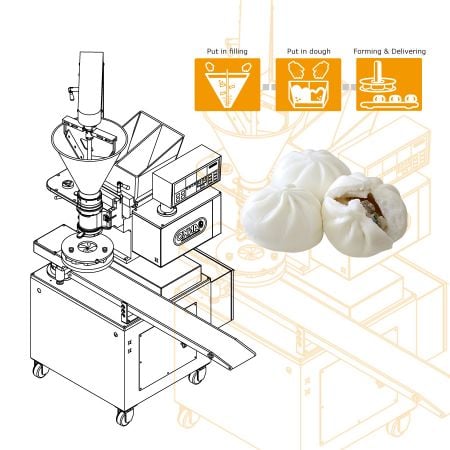

The client, a Chinese entrepreneur who moved to the Netherlands, started a restaurant specializing in authentic dumplings, famous for thin wrappers and generous fillings appealing to both the local Chinese community and Dutch customers. As the restaurant grew and expansion plans emerged, the client experimented with buns, producing them manually to test market demand. Positive feedback encouraged larger-scale production. Facing increasing orders and limited manpower, the client leveraged their experience with ANKO’s HLT-700XL machine and introduced the SD-97W Automatic Encrusting and Forming Machine, efficiently increasing output, maintaining consistent quality, and offering a wider variety of products for in-store dining and retail.

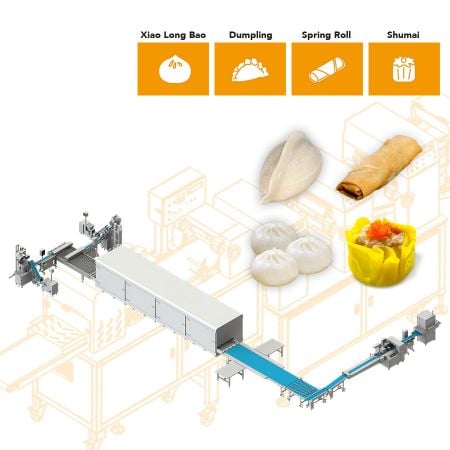

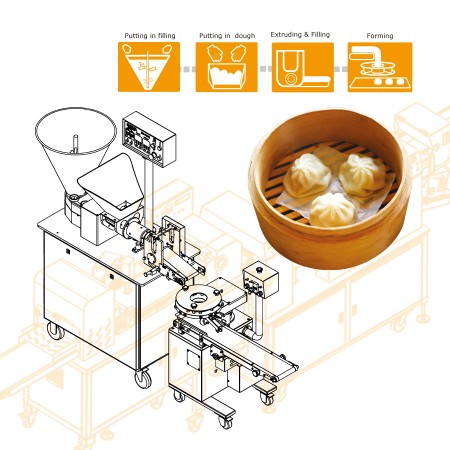

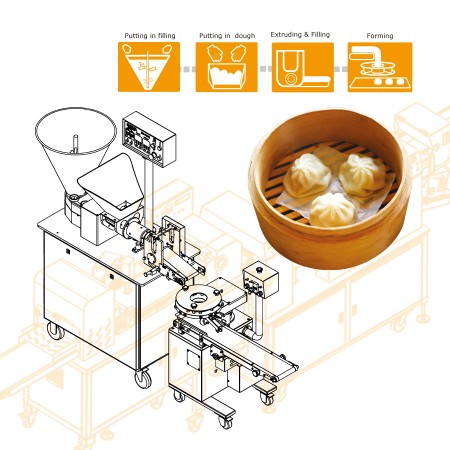

Production automation is inevitable in the food manufacturing industry, and ANKO aims to "assist manufacturers in achieving high production automation goals." In 2024, we launched the "Xiao Long Bao Integrated Production Line" as an integration concept to connect various related production parts. Within a year, ANKO successfully launched the world's first Xiao Long Bao Production Line, supported by our "automated food production solutions" system to further increase food production efficiency and reduce overall labor requirements. ANKO ensures that smart technology is applied to your food production process to increase product quality, consistency, and taste to provide competitive advantages.

The global food market is rapidly changing. When peak seasons arrive, urgent orders always come quickly. When facing global labor shortages and ever-changing consumer tastes, food companies are eager to find more flexible and efficient production models to respond to market demand. ANKO's newly launched "Integrated Production Line" is designed to resolve the difficulties associated with food manufacturing. Our newly designed production lines include Dumplings, Shumai, Spring Rolls and Xiao Long Bao, providing everything from feeding systems, forming machines, to packaging and various inspection equipment. ANKO's streamlined labor configuration has a daily output of 150,000 pieces! We can also provide solutions for other food products, configuring appropriate production equipment to optimize efficiency and implement a smooth integrated transition.

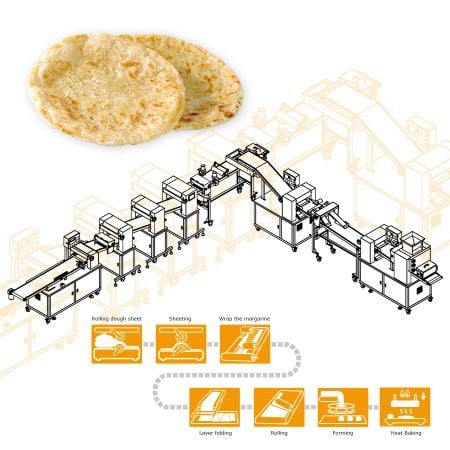

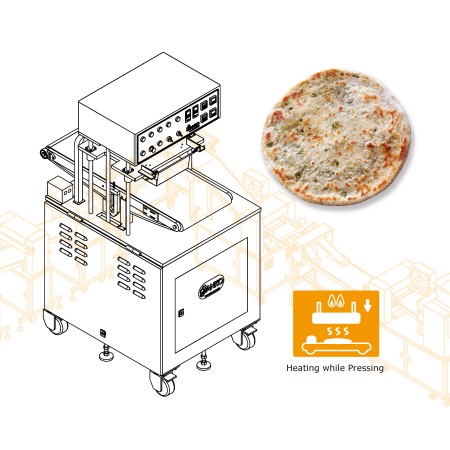

This ANKO client is a well-known food manufacturer in Bangladesh, and their business scope includes multiple food fields. They have been using semi-automatic equipment to produce Paratha to supply their domestic market demand. To expand their Paratha sales internationally, this client purchased ANKO’s fully automated food machines to produce an estimated 100,000 pieces per day in order to meet the global market demand. This ANKO return customer is confident in our high-quality machine performance and the professional support services we provide. Our team customized a Triple Line High Capacity Paratha Production Line for this company. With the assistance of ANKO’s Bangladeshi local distributors, this client visited our Taiwan headquarters to conduct trial machine operations, and the results successfully met the client’s required production requirements and food specifications.

An ANKO client operates restaurants and takeout shops in Australia; they also own a food factory and sell their products in supermarkets. Their food items include Har Gow (Shrimp dumplings), Tang Baos, Dumplings, and Buns. Recently, many food businesses have started using automated production equipment due to labor shortages in Australia. This client is a great example. They purchased ANKO’s HLT-700XL Multipurpose Filling And Forming Machine, EA-100KA Forming Machine, SD-97SS Automatic Encrusting And Forming Machine, and other ANKO machines to produce a wide range of products. They successfully transitioned to automated food production, increased productivity, and resolved labor issues. ANKO’s engineers helped the client maintain the machines and develop new Har Gow flavors successfully.

This customer's factory is in California which has the largest population of Chinese people in the United States. They specialize in the manufacturing and wholesaling of Chinese food including Dumplings, Har Gow, Baozi, Spring Rolls, Shumai, etc. They have a distribution center in their local area, and consumers can buy their products in supermarkets, direct wholesale, and from other distributors. This customer owns ANKO’s HLT-700XL Multifunctional Filling and Forming machine, SD-97W Automatic Dumpling Machine, HSM-600 Automatic Shumai Machine, and the SRP Automatic Spring Roll Pastry sheet machine. As the demand for spring rolls has continued to increase, the customer learned about ANKO's latest SR-27 Spring Roll Machine and they immediately contacted us to arrange a demonstration. In addition to the vegetable and pork Spring Rolls the customer originally produced, they requested to test run using cheese and apple cinnamon fillings because of their desire to develop innovative new Spring Roll products and capitalize on the growing Sweet Spring Roll market.

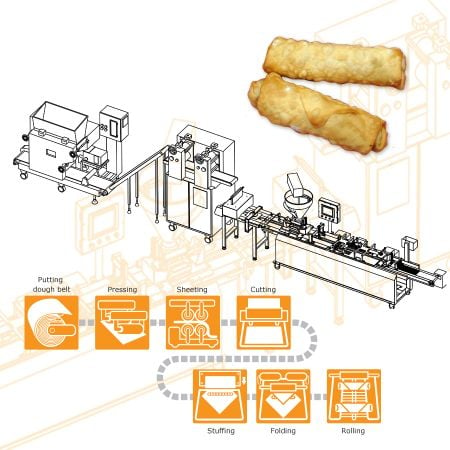

An ANKO client based in Los Angeles has 35 years of commercial food sales experience in supplying Shanghainese Spring Rolls, Meats, Baos, canned goods, sauces and seasonings to wholesalers and restaurants. Recently, they saw the increasing demand for Egg Rolls, therefore they decided on establishing an automated Egg Roll production line. ANKO’s ER-24 Automatic Egg Roll Machine was the perfect machine for this client, and after a few product test runs and recipe adjustments, ANKO successfully assisted this client in creating a new food production line, and in doing so, create a new business opportunity for them.

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers was looking for an opportunity to turn a vacant factory in Indonesia into a profitable automated food business. Because this client had previously purchased ANKO’s HLT-700XL, SR-24 and an ANKO commercial deep fryer, they had decided to seek ANKO’s assistance to provide them with professional automated production line equipment and support to sell croquetas (croquette) in Indonesia.

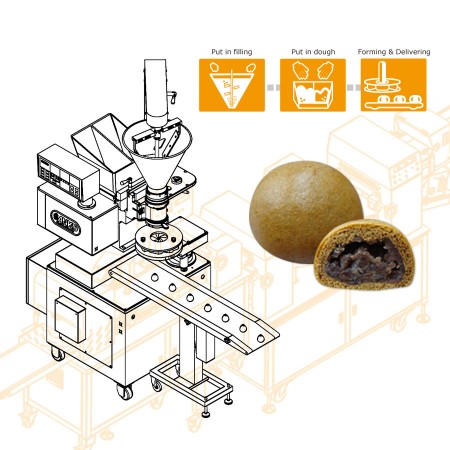

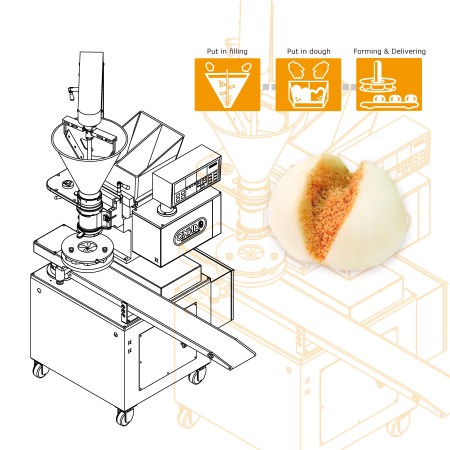

This company owns a bakery, selling various buns and bread. Brown sugar is a common ingredient in Asian cooking, and many people consider it to be healthy food. The client develops a stuffed bun which dough is added brown sugar and which only weighs 12-15g. Since they started selling brown sugar steamed buns, the great popularity has made them hard to handle so many orders. Knowing ANKO is the expert in designing food processing equipment, they contacted us for solutions.

The client has production lines for bakery and ethnic food, including baozi, siomay, hargao, bread, etc. In order to provide the most fresh and best quality food to customers, they have food factories, central kitchens, packaging production line, cooling and frozen facilities. Because their present products stably make profits, they plan to expand the other Chinese dim sum production line to produce spring roll. Hope it can create a new market. Prior to this expansion, the client bought several machines from ANKO for making baozi and satisfied with machine's quality and ANKO's after-sales service, so that ANKO spring roll wrapper machine, which production capacity is high and stable, is exactly what they want. Therefore, it is our pleasure to cooperate with them and satisfy their requirements.

An ANKO client operates a baking factory in the Netherlands and exports their baked goods to various European countries, including the UK, France, Germany, and Luxembourg. Recently, this client ventured into the production of Chinese Dim Sum and learned about ANKO through local food industry contacts. Due to our excellent reputation, professional expertise and quality service in the industry, we successfully created an automated Har Gow production line for making high-quality Har Gow that met the client’s expectations.

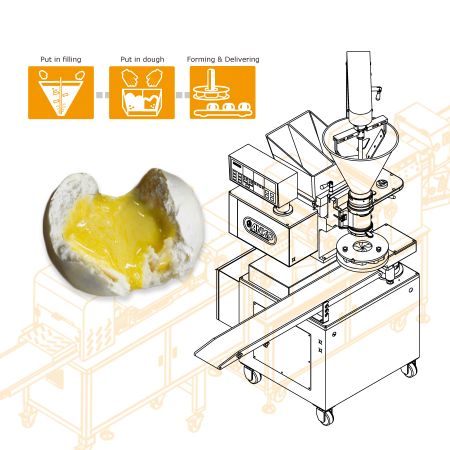

The dining group operates Cantonese restaurants, hot pot buffets, and Japanese buffets for satisfying various consumers. They used to make their food products by hand. With more and more restaurants opened, the continuing growth in demand for steamed custard buns in all types of their restaurants prompted the company to invest in a new machine to extend its offerings. it's a turn to transform handmade into automatic production. Chefs hoped to maintain food quality while cutting cost so that they found ANKO. We have the largest market share in Taiwan food machine industry and our machine can help them meet the growing demand. After testing our SD-97W, they are satisfied with the multifunctional encrusting and forming machine which offers them the flexibility in production. In addition to steamed custard bun mentioned above, they also use the machine to produce sesame balls.

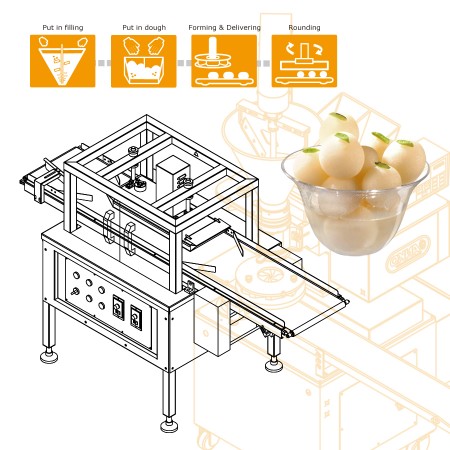

The Indian British brothers own two dessert shops. For cutting cost, they went to a machinery show and got much of an impression of ANKO. Through simple communication, they decided to come to Taiwan for a test-run. In addition to traditional ball-shaped rasgulla, it's successful to produce circular shape and long shape with shaping devices. Due to our quick and comprehensive services, the clients ordered two sets of machines for each dessert shop.

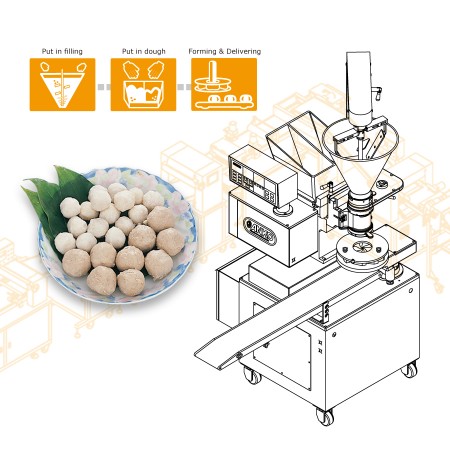

The client has two fishing vessels and two fish processing plants to process the six-ton daily catch. One plant is dedicated to mince fish into fish paste, and the other plant is for the production of fish balls and fish products. He purchased a HLT-700XL Multipurpose Filling & Forming Machine and a SD-97W Automatic Encrusting and Forming Machine from ANKO. The HLT-700XL is used for producing deep-fried fish snacks — a new offering made of springy fish paste with a crispy wrapper. And the SD-97W is for making stuffed fish balls. The client's new plant covers 10,000 square meters and employs around 50 people. Their products are mainly sold to local supermarkets in Indonesia such as Carrefour.

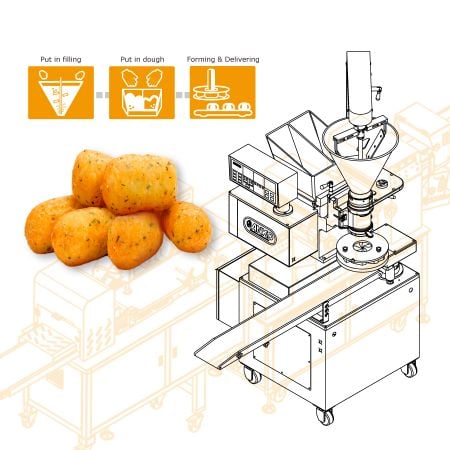

The client runs meat processing business which has long history and gains high market share. Now it is the turn that the second generation entrepreneur takes over the company. With current frozen equipment and packaging machinery, they would like to increase efficiency and develop other snacks with product line expansion. ANKO's machinery features multifunction. Take the Automatic Encrusting and Forming Machine as an example, various kinds of dough and filling are suitable for the machine; through parameter adjustment, a wide range of products can be made with one machine. For manufacturers, it definitely a worthy investment to receive a high price/performance ratio.

The client's company had gained a firm foothold in India and then he planned to expand into the U.S. market so that having accurate food quality control and standardization, product line extension, productivity improvement are essential. He compared ANKO with other food machine suppliers and found ANKO is superior to them. ANKO has higher market share in India, offers wrapper and filling recipe to meet individual need, and has years' experience in designing food production routes and supply chain integration. Finally, he chose ANKO as their business partner.

The client sells a great variety of foods. Although glutinous rice ball was not one of the main products, he needed a solution to produce glutinous rice balls effectively. Therefore, he visited ANKO's booth at a Hong Kong exhibition. Compared to other glutinous rice balls, the client's filling recipe contains more ingredients, including peanut powder, coconut powder, and sugar powder, which makes workers hard to fill the same ingredient quantities into each glutinous rice ball. Nevertheless, it is also difficult for machine to extrude powder filling because it easily tends to clump up and clog the filling system. Therefore, for making stuffed food with powder filling, ANKO's Automatic Encrusting and Forming Machine with a special designed powder filling system is highly recommended.

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy recipes to catch customer's heart. With the increasing popularity of dim sum, he began running a food factory. As seeking food equipment, he knew that ANKO has years of experience in the dim sum making machinery and provides customization in accordance with individual needs and factory planning. Therefore, he decided to cooperate with ANKO.

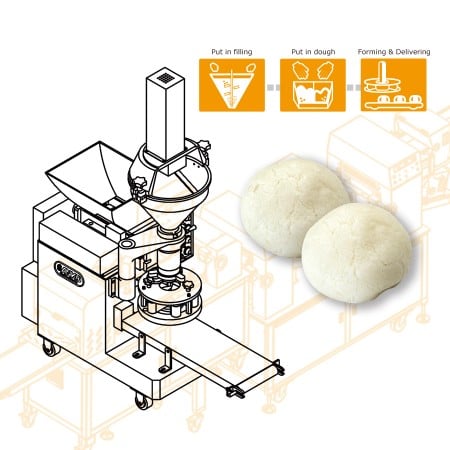

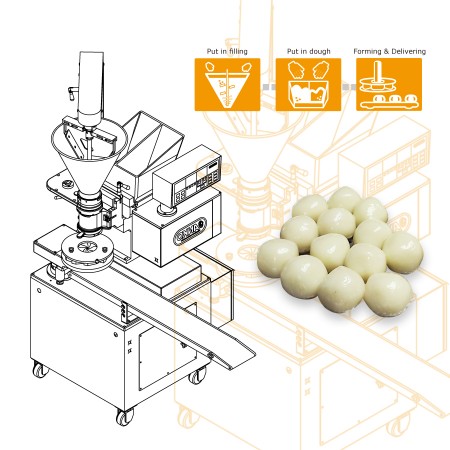

The confectionery factory has established nearly 100 years. They expand their Indian sweets and snacks market along the Indian migration route across the globe. In 2009, in order to increase production capacity and save labor costs, the client contacted ANKO and inquired about the rasgulla automatic production line, which combines SD-97W Automatic Encrusting and Forming Machine with RC-180 Automatic Rounding Machine. In the process of trying out the SD-97W, we adjusted the extruding pressure to maintain the texture of rasgulla. The client was satisfied with the final products and full of confidence in the investment, so he placed an order for three production lines. "Is ANKO trustworthy?" the answer is obvious.

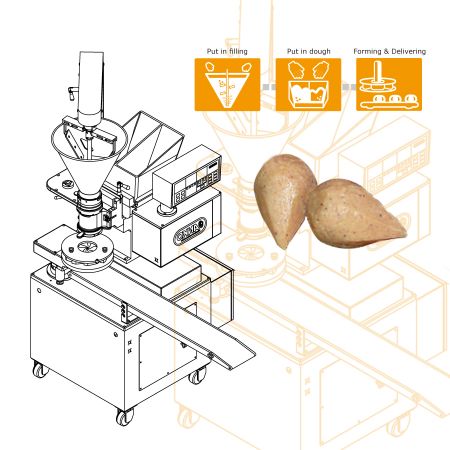

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online, in supermarkets or deli. Selling products in multi sales channel had leaded to an increasing demand, so the company's owner, via a dealer, had been looking for a supplier who can offer an automated production solution for making kubba. It's always a challenge to make a machine work well with a new recipe. In this case, we had a problem in forming kubba because the crust was too sticky. The just formed kubba would stick to the shutter unit and then be broken while the shutter unit opened. Through recipe and temperature adjustment, ANKO team solved the problem successfully.

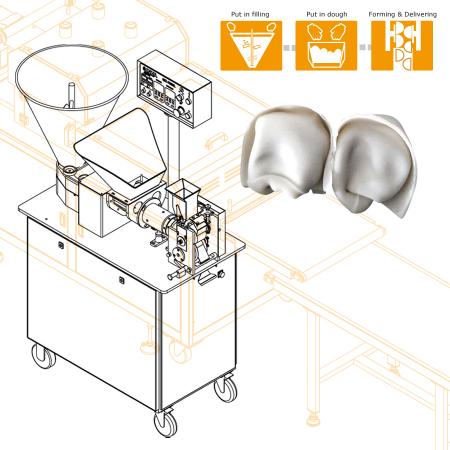

20 years ago, a Chinese restaurant opened, serving Shanghai style dim sum which then became popular with the local people. However, the issues of labor shortage, limited capacity, and workload drove the owner to make a change. During his visit to ANKO, he had good experience with ANKO's machine trial service. During the visit, both of us could have a better understanding of each other. Based upon his ideas, concerns, and needs, we customized two forming molds to help him mass-produce shanghai wontons that were complicated to fold by hand. With ANKO's HLT-700XL, now the owner doesn't bother to recruit and train cooks and can increase capacity to meet demands.

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply and problems with staff management had come out. It took an average of three months for a new employee to become fully productive. Therefore, the client started finding an automatic solution. At first, the client knew ANKO by searching from the Internet and visiting IBA Munich, which is a trade show held in Germany every two years, but he didn't contact us until the next IBA Munich. He placed an order without having a machine trial because he thought ANKO had considerable experience in food machinery. He purchased an HLT-700XL Multipurpose Filling and Forming Machine and an EA-100KA Forming Machine. With these two machines, he could make a wide variety of dishes, such as dumpling, steamed dumpling, crystal dumpling, fun guo, soup dumpling, increase production capacity and decrease labor costs. Moreover, when ANKO's engineer conducted on-side commissioning, our engineer helped solve his problem that soup dumplings had no soup.