ANKO Developed New Sweet Spring Rolls for a US Client to Resolve Production Issues of Fillings

This customer's factory is in California which has the largest population of Chinese people in the United States. They specialize in the manufacturing and wholesaling of Chinese food including Dumplings, Har Gow, Baozi, Spring Rolls, Shumai, etc. They have a distribution center in their local area, and consumers can buy their products in supermarkets, direct wholesale, and from other distributors. This customer owns ANKO’s HLT-700XL Multifunctional Filling and Forming machine, SD-97W Automatic Dumpling Machine, HSM-600 Automatic Shumai Machine, and the SRP Automatic Spring Roll Pastry sheet machine. As the demand for spring rolls has continued to increase, the customer learned about ANKO's latest SR-27 Spring Roll Machine and they immediately contacted us to arrange a demonstration. In addition to the vegetable and pork Spring Rolls the customer originally produced, they requested to test run using cheese and apple cinnamon fillings because of their desire to develop innovative new Spring Roll products and capitalize on the growing Sweet Spring Roll market.

Sweet Spring Rolls

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Combining Technology and Experience! ANKO Successfully Solves the Production Issue of Sticky Cheese

Cheese rolls are often presented as appetizers or snacks. When the customer approached ANKO, they informed us that the finished product should weigh 35 grams and that Mozzarella cheese would be used for production. When making the cheese filling using automated machines, the issue of stickiness often arises. ANKO’s SR-27 Spring Roll Machine is designed with a filling hopper that avoids excessive stirring of the filling, which helps prevent a rise in temperature and stickiness caused by overmixing. Additionally, the filling mechanism has a special anti-stick design that allows for easy dispensing of slightly sticky fillings.

During the cheese filling testing conducted by ANKO engineers, the cheese rolls were perfectly shaped, and the weight requirements set by the customer were met. The customer mentioned that using only Mozzarella cheese often resulted in a softer than desired texture. Thus, the customer worked with his team on new recipes which included a variety of cheeses. With the assistance of ANKO engineers, the newly produced cheese rolls had the desired texture thus meeting the customer's requirements.

Solution 2. ANKO assisted our client switch to automated production and kept the Spring Rolls’ original textures via recipe optimization

Another filling option desired by the customer was an apple cinnamon version. To make the filling, all fresh apples need to be diced. The customer's transitioning from hand-made to automated production created challenges; as the machine processes the filling ingredients, it causes it to release more liquid, resulting in soggy Spring Roll wrappers and affecting the overall texture. To produce crispy Apple Cinnamon Spring Rolls with automated machinery, ANKO’s food researchers modified the recipe to ensure results that met the client’s expectations…(Contact ANKO immediately for more information)

After ANKO’s adjustments, the apple cinnamon Spring Rolls were successfully formed, and the customer approved the product texture after frying. This client also discussed the modern trend of pursuing healthier diets and requested assistance in a change from deep-frying to baking in an oven to reduce the fat content. The baked Spring Rolls maintained their appetizing appearance, with ANKO’s professional assistance and baking techniques, the texture remained crispy even without the use of oil.

ANKO’s engineers and food researchers worked together to create production solutions to meet our client’s product specifications. The final Cheese Rolls and Apple Cinnamon Spring Rolls turned out successfully. ANKO’s subsidiary office in Los Angeles offers on-site product testing services, and our experienced engineers can offer you professional advice on how to improve your products. We sincerely welcome you to contact us for more information or to schedule an appointment.

Sweet Spring Rolls are often consumed as appetizers and desserts, so their size may not be as long as the regular ones. Thus, ANKO has developed the Mini Spring Roll, which is suitable for catering companies, bakeries, dessert start-ups, and manufacturers. The dimensions of the Mini Spring Roll range from 73 mm in length, weighing between 22 to 26 g and 85 mm in length, weighing between 28 to 36 g depending on the filling ingredient. Even smaller sizes can be customized.

Food Equipment Introduction

- Load the hoppers separately with batter and filling ingredients

- The heating drum cooks the Spring Roll wrapper

- Spring Roll wrappers are cooled

- Wrappers are divided into specific sizes

- Filling

- Folding

- Forming

- Rolling into final product

Pressure-free filling system, designed for various sweet and savory fillings

ANKO's SR-27 Spring Roll Machine features a pressure-free filling system that avoids excessive mixing of the filling, allowing the retention of its texture and integrity. This design is especially beneficial when making vegetable-only fillings for spring rolls, as there is no need to pre-cook the filling or incorporate food additives. The filling system simulates the action of hand-grabbed fillings, making it suitable for various types of fillings, such as vegetables with low lubricity, loose-textured cooked meat fillings, chocolate sauce with poor flowability, apple fillings with a grainy texture, and sticky cheese fillings. The SR-27 Spring Roll Machine can handle all these fillings in a single production run.

Furthermore, ANKO's pioneering Food Lab contains over 700 recipes from different cuisines worldwide. The experienced food researchers can optimize the recipes according to the desired texture specified by the customer or assist in developing new products, thereby accelerating the product development and market launch timeline.

- Solution Proposal

A highly productive Spring Roll Machine that can fulfill large volume orders and create increased profits

ANKO did

ANKO has developed the industry's first fully automatic Spring Roll Machine with an exclusive patented design. The SR-27 Spring Roll Machine operates with great reliability and can produce standardize high quality products filled with different types of fillings. This helps food industry operators improve their competitiveness and gain an edge on the market.

ANKO can help you more

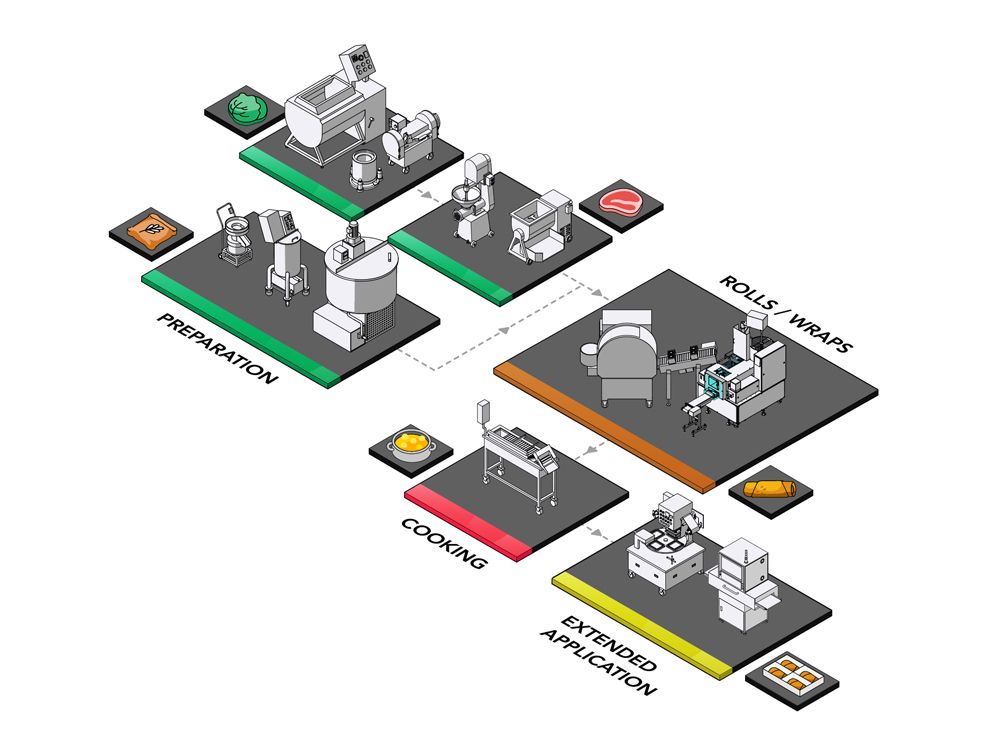

For large-scale food factories or highly automated food manufacturers, ANKO offers comprehensive Spring Roll Production Solutions. It includes all necessary equipment for food processing, such as vegetable chopping machines, meat grinders, mixers, batter mixers, and batter storage tanks. ANKO offers all core component which includes the forming and wrapping device, as well as cooking, packaging, and foods safety inspection equipment and for the later stages of production. All necessary equipment for producing Spring Rolls is available.

If you are interested in more information, please click Learn More or fill out the inquiry form below.

- Machines

-

SR-27

ANKO’s SR-27 Spring Roll Machine is fully automated and requires only one person to operate. The production begins from Spring Roll wrapper-making with the output of 2,400 to 2,700 pieces per hour and approximately 20,000 pieces per day; this making it ideal for food factories with high production demand. Spring rolls in both regular and miniature sizes, ranging from 73mm to 100mm in length and weighing between 22g to 50g, can be effortlessly produced to accommodate diverse preferences and requirements. Most Spring Roll producers utilize semi-automatic machines for their production. This requires pre-made Spring Roll wrappers from other suppliers making it harder to have full control of the quality, food costs, and necessitates more labor on the production line. Hence, many business owners are switching to a fully automated Spring Roll production line to maintain full control over their production costs and food quality.

SRP Series

ANKO offers another innovative solution – the SRP Automatic Spring Roll Wrapper Production Line, designed to help clients produce high-quality Spring Roll Pastry effortlessly. By pouring batter into the hopper, this advanced machine automatically produces Spring Roll Wrappers at high temperatures through the baking drum. The wrappers are then cooled by a fan, ready to be precisely cut and stacked. Its automatic and flexible cutting mechanism allows easy adjustments, enabling you to produce wrappers of your preferred size by simply changing machine parts and setting parameters. With an impressive productivity rate of 2,700 pieces per hour and standardized size products, the SRP Automatic Spring Roll Wrapper Production Line brings unmatched benefits to your business and effectively addresses the challenges of insufficient employees.

- Country

United States

United States Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in the United States with advanced automated food production technology for making Dumplings, Egg Rolls, Empanadas, Spring Rolls, Burritos, Mochi, Quesadillas, and Spring Roll Wrappers. We also offer integrated solutions for popular foods such as Samosas, Momo, Pierogi, Tortillas, Shumai, Tapioca Pearls, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.To provide timely and localized service, ANKO has established a branch office in the United States. With a dedicated team based locally, we’re able to offer in-person consultation, machine demonstrations, and responsive after-sales support tailored to the specific needs of our American clients.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

The most consumed Spring Rolls are usually filled with vegetable or vegetable and meat fillings, they are often served as side dishes or snacks. With the trend for diversification of diet and people's love for trying new things, Spring Rolls are no longer limited to savory fillings. Sweet-filled Spring Rolls have gained popularity as appetizers and desserts and are increasingly common at parties, gatherings, and restaurants. For example, cheese rolls are a popular finger food, chocolate-banana rolls which originated in Indonesia have gained worldwide popularity due to their simple preparation and delicious taste. Other variations, such as apple rolls, custard rolls, and red bean rolls, also have their own fan base. Finished rolls are often served with ice cream, whipped cream, caramel sauce, honey, and other accompaniments. Cheese rolls, chocolate rolls, and others can also be purchased in the market and only require three minutes of deep frying before serving. Health-conscious consumers may choose to bake or air-fry the Spring Rolls to reduce the consumption of oil while still enjoying the delicious taste.

- Handmade Recipe

-

Food Ingredient

Spring Roll Wrapper-Flour/Salt/Water, Filling-Mozzarella cheese/Feta cheese/Parslehy

Making Wrappers

(1) Place flour with a pinch of salt in a bowl, add water to the flour and mix until it becomes a smooth batter (2) Let the dough rest for 30 minutes. Heat a pan on low and add cooking oil (3) Place a spoon full of batter into the heated pan to make Spring Roll wrappers (4) Repeat steps above to make more Spring Roll wrappers

Filling Ingredients

(1) Chop parsley, and mozzarella cheese, add crumbled feta cheese (2) Mix all three ingredients together

Assembling the Spring Rolls

(1) Take a piece of Spring Roll wrapper and place the filling ingredients on top (2) Fold the bottom of the wrapper on top of the filling ingredients, then fold the two sides to cover (3) Wrap the Spring Roll and use batter to seal the end (4) Deep-fry the Spring Roll in hot oil until golden brown and crispy

- Downloads

English

English