Indian Rasgulla Automatic Production Line Equipment Design

The confectionery factory has established nearly 100 years. They expand their Indian sweets and snacks market along the Indian migration route across the globe. In 2009, in order to increase production capacity and save labor costs, the client contacted ANKO and inquired about the rasgulla automatic production line, which combines SD-97W Automatic Encrusting and Forming Machine with RC-180 Automatic Rounding Machine. In the process of trying out the SD-97W, we adjusted the extruding pressure to maintain the texture of rasgulla. The client was satisfied with the final products and full of confidence in the investment, so he placed an order for three production lines. "Is ANKO trustworthy?" the answer is obvious.

Rasgulla

ANKO Team Research Problem Solving or Solution Delivery

ANKO's SD-97W moderately extrudes rasgulla without damaging its spongy texture.

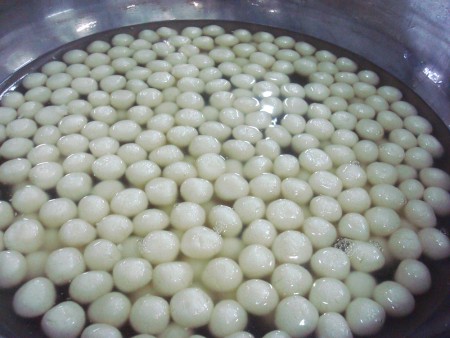

Rasgulla is one of chenna-based desserts, springy but not firm, and can absorb sugar syrup like a sponge. Its chewy and very sweet tastes are the Indians' favorite tastes.

However, the encrusting machines on the market press and extrude chenna with high pressure, which make the texture of the rasgullas too firm. Conversely, ANKO's SD-97W with a special extruding system has lower extruding pressure to maintain the handmade texture and taste.

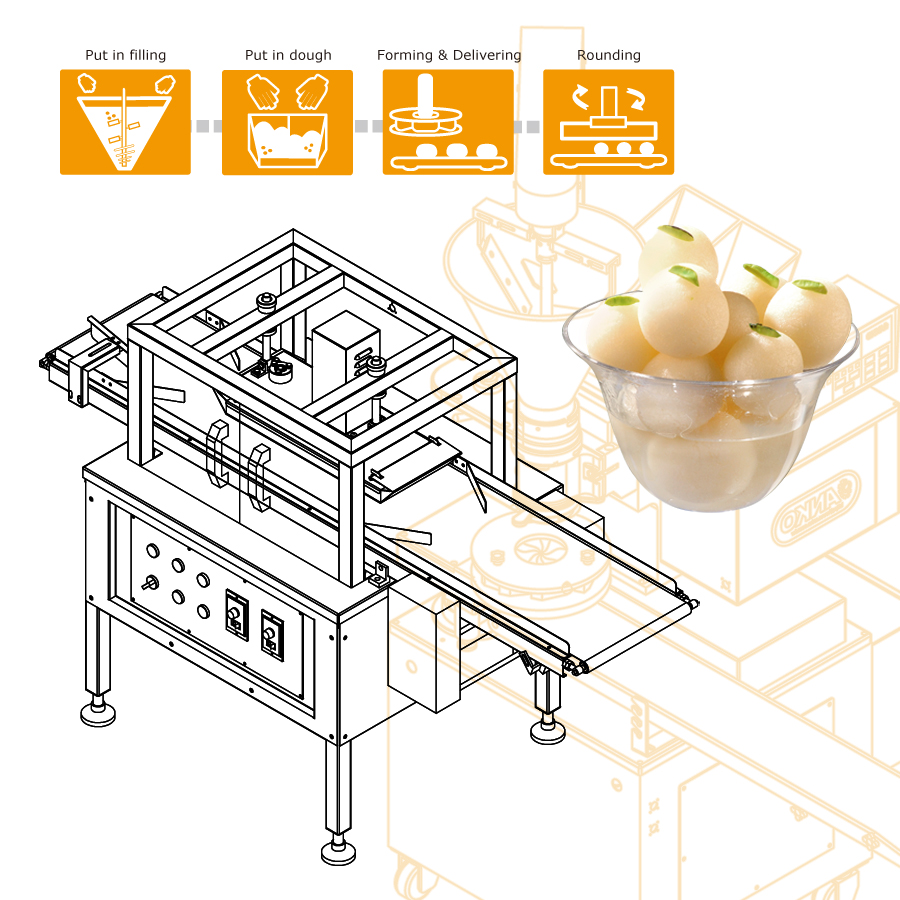

The client set three sets of rasgulla production lines – the SD-97W Encrusting and Forming Machine and the RC-180 Rounding Machine to produce round rasgullas. The hourly production capacity can be up to 10,000 pieces. Finally, all the rasgullas made by multiple production lines are collected by one conveyor for boiling. This kind of production line planning for food factory can increase efficiency in manufacturing.

Food Equipment Introduction

- Bring milk to a boil and then add lemon juice to curdle milk.

- Drain chenna (curd cheesse), then put it into the hopper of SD-97W.

- The chenna is extruded into a cylinder and divided by the non-patterned shutter unit.

- RC-180 rolls each divided chenna into a small ball.

- Put chenna balls into sugar syrup and cook.

The fundamentals of the rounding machine. How to roll products into perfect round balls.

The RC-180 rounding machine is designed based on a human action of rolling a thing into a ball. The machine is equipped a rectangular rolling device at the top and a conveyor at the bottom. They rotate in different directions as the left and right hand action of rolling a ball. For bigger products, the rolling device and conveyor will be made longer and wider, and adjusted to spin in a larger circle. It is because if the food is longer and the rounding device spins in a small circle, then the rounding device and conveyor will only rub the top and bottom sides of the food.

Also, according to the rasgulla size, the rolling device can be moved upwards or downwards to a proper height so that the texture of the rounded rasgullas won't be damaged.

Rasgullas are rapidly rolled by RC-180 rounding machine.

Semi-finished rasgullas are conveyed to be rounded by the RC-180 machine. The rounding device and conveyor spin in opposite directions like the human action of rolling a ball. Up to 3,000-3,600 pieces can be processed in an hour.

The prevention of dough sticking to shutter unit was considered when designing it.

In order to prevent dough from sticking on the shutter unit, our engineers minimized the contact time and surface when the shutter unit cuts and forms the products. Although there is no doubt that the structure of the shutter unit has a significant impact on finished products, the shutter speed is the key to success. At the moment the shutter opens and closes, a product is formed perfect and pleasing in shape.

- Solution Proposal

ANKO Rasgulla Making Machine Increases Production Capacity for a Successful Food Business

ANKO did

With India being the world's most populous country, the food market is set to boom. Rasgulla, a classic sweet, is omnipresent in restaurants, streets, and homes. ANKO believes in the tremendous business opportunities in the Indian food market. Making Rasgulla can be an easy process with ANKO's food machine. In this case, the client purchased three Rasgulla Production Lines based on our professional experience and service.

ANKO can help you more

In addition to Rasgulla forming and rounding machines, ANKO can also plan a mixer for making the chenna and packaging and food x-ray machines for quality control. Switching to automation eliminates the need for extensive manual work, saving time and effort. For the best Rasgulla Production Solution, please click Learn More or fill out the inquiry form below.

- Machines

-

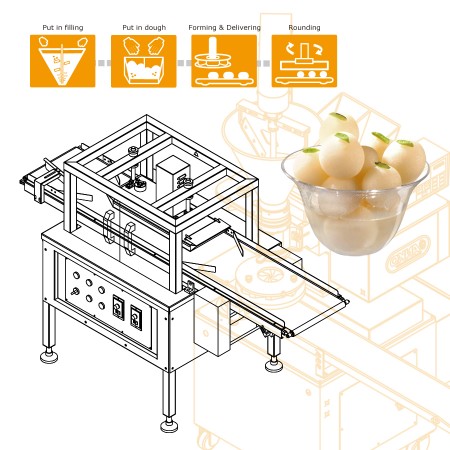

SD-97W

SD-97W Automatic Encrusting and Forming Machine is designed to produce stuffed food products. The shutter unit can divide stuffed or plain dough into different shapes of products. In this case, chenna is divided by SD-97W into standard size balls, which are then rolled by RC-180. There are also patterned or non-patterned shutters available for customers to choose. The machine is capable to produce baozi, coxinha, kubba, cookie, etc. Additionally, the SD-97W is introduced the IoT system that intelligently integrates food production lines. Through mobile devices, production status can be monitored remotely, and the IoT also produces machine maintenance schedule reminders, significantly reducing the risk of downtime.

- Country

India

India Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in India with advanced automated food production technology for making Layered and Stuffed Paratha, Spring Roll Wrapper, Samosa Pastry, and Rasgulla. We also offer integrated solutions for popular foods such as Samosa, Momo, Dumplings, Chapati, Kachori, Pani Puri, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Rasgulla is a popular dessert in India, Bangladesh, and many parts of South Asia. Making chenna is the first step to make rasgulla. Some people might not know what chenna is. Actually, it is a type of curd cheese. Then, slowly cook small chenna balls in sugar syrup. They will puff up as cooking to be sweet, soft, and spongy rasgullas. Nowadays, canned rasgullas are available everywhere.

- Handmade Recipe

-

Food Ingredient

Whole Milk/Lemon Juice/Sugar/Water

How to make

(1) Heat the milk and stir occasionally until boiled. (2) Add a little lemon juice and stir well. (3) If the milk does not curdle completely, add a little more lemon juice. (4) When the milk curdles completely, drain the whey with a cheese cloth. (5) Rinse the chenna (cottage cheese) to get rid of lemon juice. (6) Tie the cloth and squeeze out excess water from the chenna, then hang it to drain water for 45 minutes. (7) Take the chenna out of the cheese cloth and knead it until smooth. (8) Divide it into equal portions and roll them into small balls. (9) Add sugar and water into a pot and bring the sugar syrup to a boil. (10) Add rasgullas into the pot. (11) Cover with a lid and slowly cook them in the sugar syrup over medium heat. (12) Stir them occasionally until they are cooked and doubled in size, then turn off the heat. (13) Cool down and chill them before serving.

- Downloads

English

English