Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

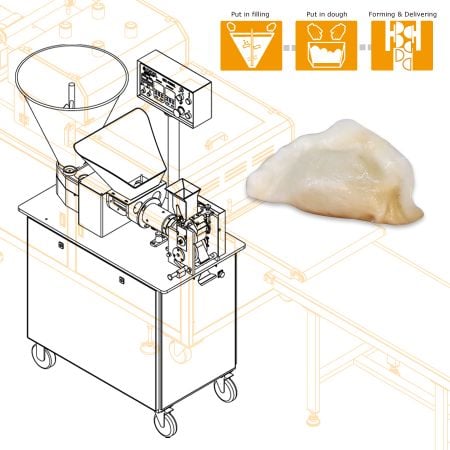

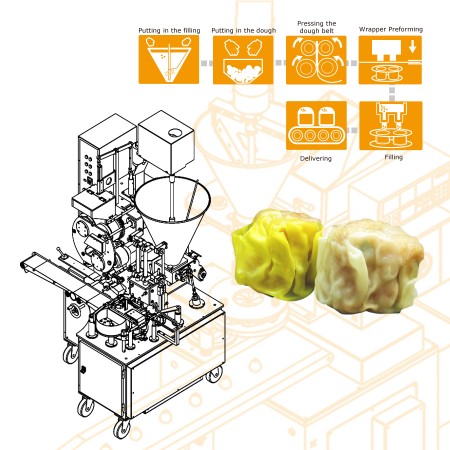

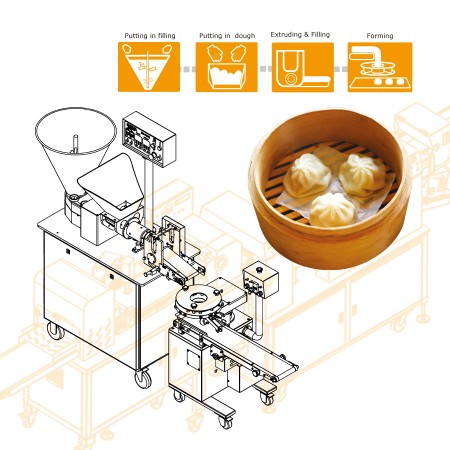

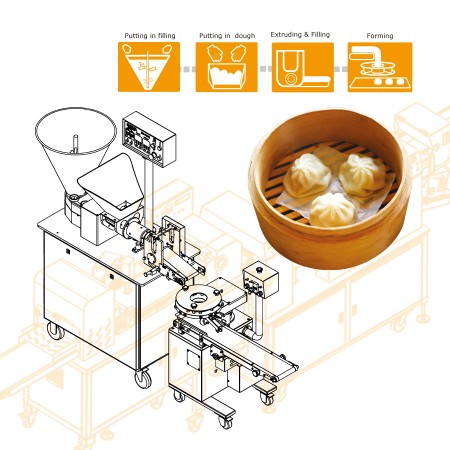

An ANKO client operates restaurants and takeout shops in Australia; they also own a food factory and sell their products in supermarkets. Their food items include Har Gow (Shrimp dumplings), Tang Baos, Dumplings, and Buns. Recently, many food businesses have started using automated production equipment due to labor shortages in Australia. This client is a great example. They purchased ANKO’s HLT-700XL Multipurpose Filling And Forming Machine, EA-100KA Forming Machine, SD-97SS Automatic Encrusting And Forming Machine, and other ANKO machines to produce a wide range of products. They successfully transitioned to automated food production, increased productivity, and resolved labor issues. ANKO’s engineers helped the client maintain the machines and develop new Har Gow flavors successfully.

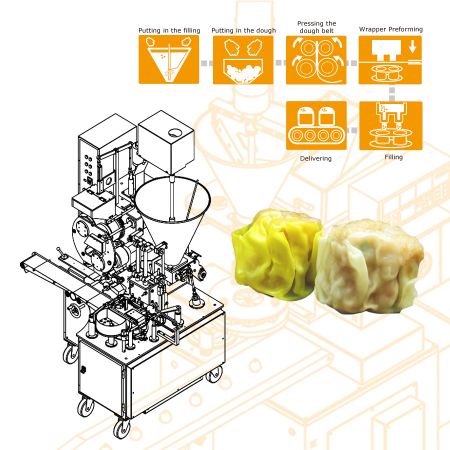

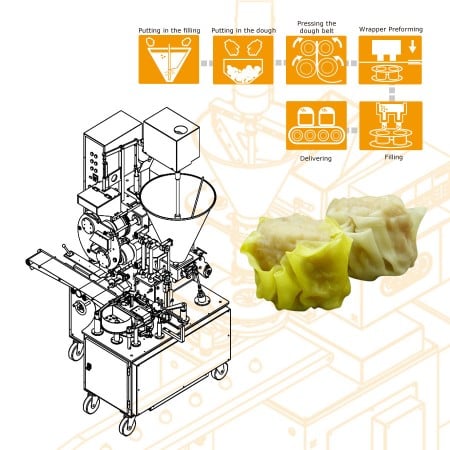

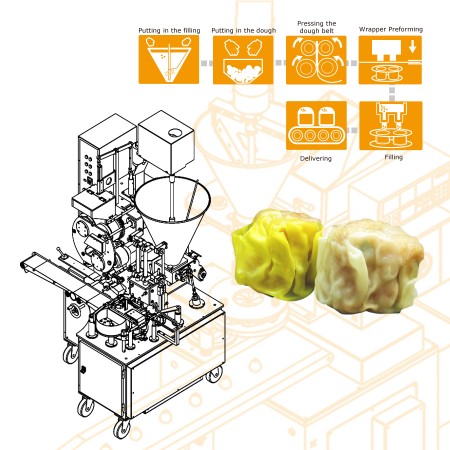

This client is a pioneer in introducing Chinese Dim Sum for European markets; they started producing and selling premade frozen Dim Sum products to many different wholesale and retail stores in Europe and accomplished great brand recognition. However, considering the high labor costs in most European countries, this client approached ANKO for an automated production assessment. In order for their business to improve and expand they decided to purchase ANKO’s HSM-600 Siumai Machine; soon after this purchase the client returned to ANKO and purchased ANKO’s HLT-700XL Multipurpose Filling and Forming Machine for producing Har Gow (Shrimp dumplings). The purchase of both ANKO machines helped them accomplish their production requirements and meet market demands.

A client and her partners started a business in Singapore. These entrepreneurs later decided to invest in the Chinese Dim Sum business in 2019. Initially they purchased equipment from a supplier in China, but the equipment was not as user friendly and required multiple employees to operate. Additionally, they encountered many difficulties and problems during their manufacturing processes. Fortunately, this very same client found ANKO. ANKO is a company that is dedicated to Quality and Productivity while offering customized production solutions for various food products and catering to each of our client’s unique requirements. This client purchased ANKO’s HLT-700XL and EA-100KA for producing dumplings and Xiaolong soup dumplings. The company supplies many schools with dumplings, and they are also working with many central kitchens. With ANKO’s equipment this client was able to establish their own brand since have enjoyed great success.

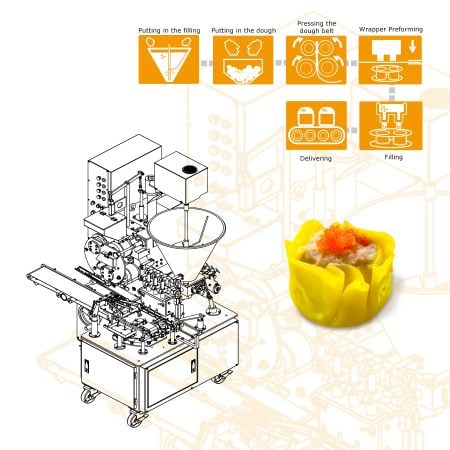

The client is a co-packer, who has been contracted by many food companies to produce Chinese food and dim sum. He has been using ANKO's double-line shumai machine for years and gives ANKO credit for the high quality machine. Recently, due to the COVID-19 lockdown, the demand for frozen food and ready-to-eat food is growing while people are unable or less willing to eat in restaurants. Therefore, a chain restaurant, who is well known for its shumai, was seeking new opportunities. The company would like to sell ready-to-heat shumai in convenience stores and supermarkets. It then contracted our client to produce the delicious shumai. As a result, our client planned to purchase another shumai machine. He said, "if you have triple-line shumai machine, we'll definitely buy one. It will be perfect."

At the restaurant, you see packs of people having their traditional Chinese food, dim sum, in Hong Kong. Dim sum has been a major meal for Hong Kong people. With increasing restaurant business, the owner of a dim sum restaurant would like to expand his production capacity with the tight kitchen space. Quotes from many food machine suppliers were higher than the owner's budget. Only Anko provided reasonable price and excellent quality. ANKO is a food making machine supplier with over 48 years of experience and their solid reputation attracts the owner to ask for their turn-key project solutions.

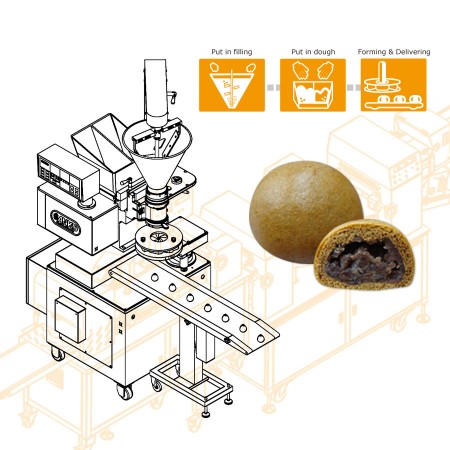

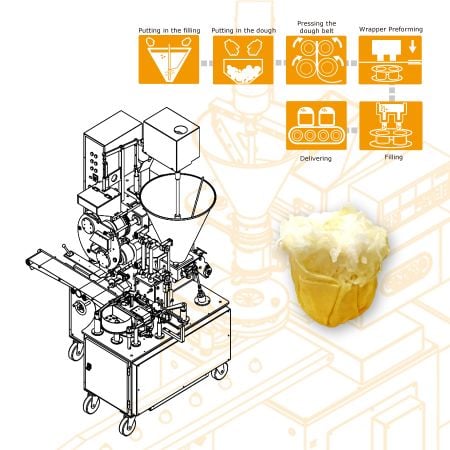

This company owns a bakery, selling various buns and bread. Brown sugar is a common ingredient in Asian cooking, and many people consider it to be healthy food. The client develops a stuffed bun which dough is added brown sugar and which only weighs 12-15g. Since they started selling brown sugar steamed buns, the great popularity has made them hard to handle so many orders. Knowing ANKO is the expert in designing food processing equipment, they contacted us for solutions.

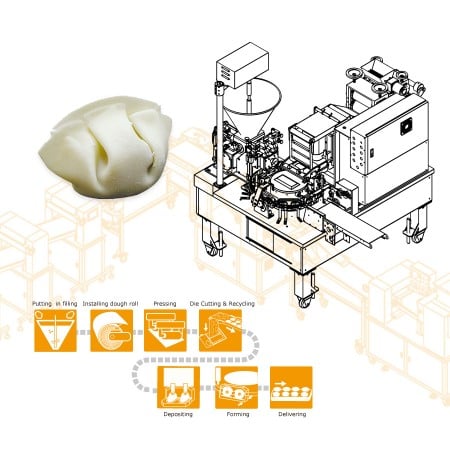

The client has production lines for bakery and ethnic food, including baozi, siomay, hargao, bread, etc. In order to provide the most fresh and best quality food to customers, they have food factories, central kitchens, packaging production line, cooling and frozen facilities. Because their present products stably make profits, they plan to expand the other Chinese dim sum production line to produce spring roll. Hope it can create a new market. Prior to this expansion, the client bought several machines from ANKO for making baozi and satisfied with machine's quality and ANKO's after-sales service, so that ANKO spring roll wrapper machine, which production capacity is high and stable, is exactly what they want. Therefore, it is our pleasure to cooperate with them and satisfy their requirements.

This ANKO client owns an international food corporation, they founded their business providing animal farming and food processing. They own multiple chicken processing food factories in Indonesia, and they have diversified their operations to include food retail business. When their Siomay business started to flourish, the market demand exceeded their production capacity, hence they started to research fully automated and highly efficient Siomay machines for their factory expansion. ANKO is a leading company in the manufacturing of professional automated food machines, and we offered this client production tests to ensure our machines could fulfill their production requirements. This client was very satisfied with ANKO’s machines and production capabilities. In the end, they purchased two HSM-600 Automatic Siomay Machines.

An ANKO client operates a baking factory in the Netherlands and exports their baked goods to various European countries, including the UK, France, Germany, and Luxembourg. Recently, this client ventured into the production of Chinese Dim Sum and learned about ANKO through local food industry contacts. Due to our excellent reputation, professional expertise and quality service in the industry, we successfully created an automated Har Gow production line for making high-quality Har Gow that met the client’s expectations.

The client begins business by manufacturing seasoning. Up to now, the company has been established for more than one hundred years, providing delicious, health, and safety food to gourmets. Since their dim sum products are on the market in 1990, they have applied ANKO's stir fryers (SF Series), dumpling making machines (HLT-700 Series), spring roll production line (SR-24), semi-automatic spring roll production line (SRPF Series) to produce and sale frozen foods, including Chinese fried rice/noodle and various kinds of dim sum, in many countries. With the growth of demands, the supply of Har Gow (Shrimp dumpling), made by hand, was unable to meet a large number of orders. This client still purchased an automatic dumpling machine with Har Gow (Shrimp dumpling) forming device from ANKO because they believe in our machine quality, which achieves the client's ideas with regard to strictly maintaining sanitary environment, controlling every production process, and providing the safest food to consumers.

The client has a central kitchen to produce and sell shumai to retailers and takeaways. The growing demand and labor costs prompted him to find an automation solution. Through his friend's introduction, he knew that ANKO is a professional food machine manufacturer. When he visited us for machine test, we used radish shreds in substitution for cassava shreds because cassava is not common in Taiwan. It's also an unprecedented attempt for us. Finally, we were glad to succeed in producing radish shumai by our shumai machine and earned recognition from the client.

The client runs a vegetarian food processing factory with HACCP as well as Halal certification. Hundreds of vegetarian food products are manufactured by the company and exported to Singapore, Australia, and other countries. With the new online shopping site, they received more orders than before, so that they planned to replace high-cost and low-efficient handmade production with automation. The client has ANKO's Automatic Spring Roll and Samosa Pastry Sheet Machine already that has been smooth without lagging, as a result, they trust in our machine quality. In this case, the client would like to produce two kinds of siew mai with one machine. One is dough wrapper; the other one is tofu skin. Both they and we wondered whether the innovation of tofu skin siew mai could be made by the same machine. The client would like to have a try because we are the only company who offers testing service.

The client operates an air catering company. They offer airline meals to many flights for serving tens of thousands of passengers who travel in and out of China. Shrimp dumpling is an exquisite dish just for business and first class passengers. Due to its complex procedure, rising wages in China, and growing demand, they decided to automate the production of shrimp dumpling. ANKO's Automatic Har Gow Forming Machine manufactures 2,000 pieces per hour and delivers standardized quality control, stable production, simple maintenance and care. They are key factors that contribute to the cooperation.

The client began his business from running a dim sum restaurant, introducing the taste of Chinese cuisine to the Dutch and developing a health-oriented menu. With the growth of business, they established a food processing factory. As looking for equipment, they found that ANKO has years of experience in the field of food equipment and customizing machinery on the basis of individual needs and factory space. Therefore, he decided to cooperate with us. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy recipes to catch customer's heart. With the increasing popularity of dim sum, he began running a food factory. As seeking food equipment, he knew that ANKO has years of experience in the dim sum making machinery and provides customization in accordance with individual needs and factory planning. Therefore, he decided to cooperate with ANKO.

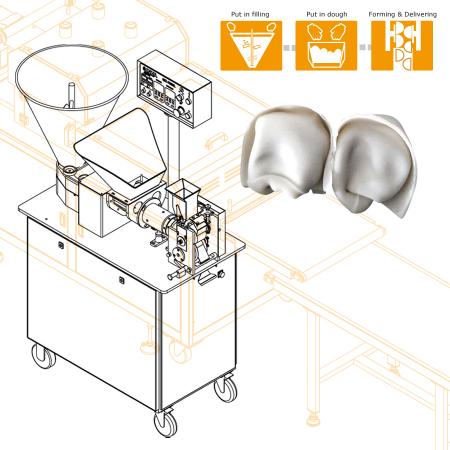

20 years ago, a Chinese restaurant opened, serving Shanghai style dim sum which then became popular with the local people. However, the issues of labor shortage, limited capacity, and workload drove the owner to make a change. During his visit to ANKO, he had good experience with ANKO's machine trial service. During the visit, both of us could have a better understanding of each other. Based upon his ideas, concerns, and needs, we customized two forming molds to help him mass-produce shanghai wontons that were complicated to fold by hand. With ANKO's HLT-700XL, now the owner doesn't bother to recruit and train cooks and can increase capacity to meet demands.

To boost production capacity, the client transitioned from manual to automatic manufacturing and contacted ANKO for a production solution. Initially, we recommended a Double-line Automatic Siomay Machine. Within two years, their number of restaurants had tripled. They then approached ANKO again to purchase another Siomay Machine to meet the demand from all their restaurants.

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply and problems with staff management had come out. It took an average of three months for a new employee to become fully productive. Therefore, the client started finding an automatic solution. At first, the client knew ANKO by searching from the Internet and visiting IBA Munich, which is a trade show held in Germany every two years, but he didn't contact us until the next IBA Munich. He placed an order without having a machine trial because he thought ANKO had considerable experience in food machinery. He purchased an HLT-700XL Multipurpose Filling and Forming Machine and an EA-100KA Forming Machine. With these two machines, he could make a wide variety of dishes, such as dumpling, steamed dumpling, crystal dumpling, fun guo, soup dumpling, increase production capacity and decrease labor costs. Moreover, when ANKO's engineer conducted on-side commissioning, our engineer helped solve his problem that soup dumplings had no soup.