ANKO Chinese Shumai Production Line - Machinery Design for a Hong Kong Company

At the restaurant, you see packs of people having their traditional Chinese food, dim sum, in Hong Kong. Dim sum has been a major meal for Hong Kong people. With increasing restaurant business, the owner of a dim sum restaurant would like to expand his production capacity with the tight kitchen space. Quotes from many food machine suppliers were higher than the owner's budget. Only Anko provided reasonable price and excellent quality. ANKO is a food making machine supplier with over 48 years of experience and their solid reputation attracts the owner to ask for their turn-key project solutions.

Shumai (Siomay)

Food Variation

Ingredients vary depending on the region. For example, Shumai (Siomay) in Indonesia can contain fish with tofu and vegetables in peanut sauce. In China, it contains pork, fish paste and shrimp whereas in the Philippines, Shumai (Siomay) is stuffed with ground pork, beef, shrimp and then wrapped in wonton wrappers. Our client is supplying Shumai (Siomay) in Hong Kong, therefore, Chinese Shumai (Siomay) is required with a recipe of flour, egg yolk, salt, water, fish paste and oil.

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Fish Paste Stickiness Issue for the Chinese Shumai (Siomay) Making Equipment

Fish Paste's stickiness was a troublesome problem for the Chinese Shumai (Siomay) processing line. During the test, the viscosity of fish paste was leaving too much paste behind and causing the frequent cleaning of stuffing section. "The Shumai (Siomay) processing equipment had to stop every 30 minutes during the process and restart again," said by ANKO engineering team. To solve the problem, they had to minimize the gap between... (Please contact us to get more information)

When fish paste becomes too viscous it can cause machine malfunctions which often requires resetting

Solution 2. 14 g Shumai (Siomay) Processing Machinery

Based on the client's requirement, Shumai (Siomay) wrapper has to be very thin and the Shumai (Siomay) has to be light. The thickness of wrapping skin would be 0.3~0.5mm and each Shumai (Siomay) would weigh 14 grams. The special requirement is not standard specifications, ANKO's engineering team needed to customize the equipment. In the end, the whole Shumai (Siomay) processing equipment was successfully designed to meet their needs.

Solution 3. Labor Cost Reduction

The client would like to reduce the labor cost and let some employees go for other production line. Thus, an automatic Shumai (Siomay) making machine was designed to solve the labor cost issue. What’s more, double line Shumai (Siomay) making machine was custom-made to increase production capability rather than a single line.

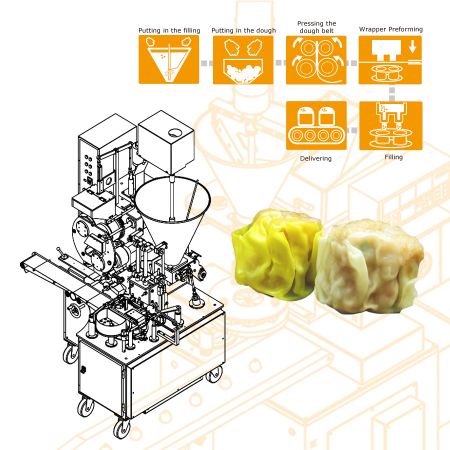

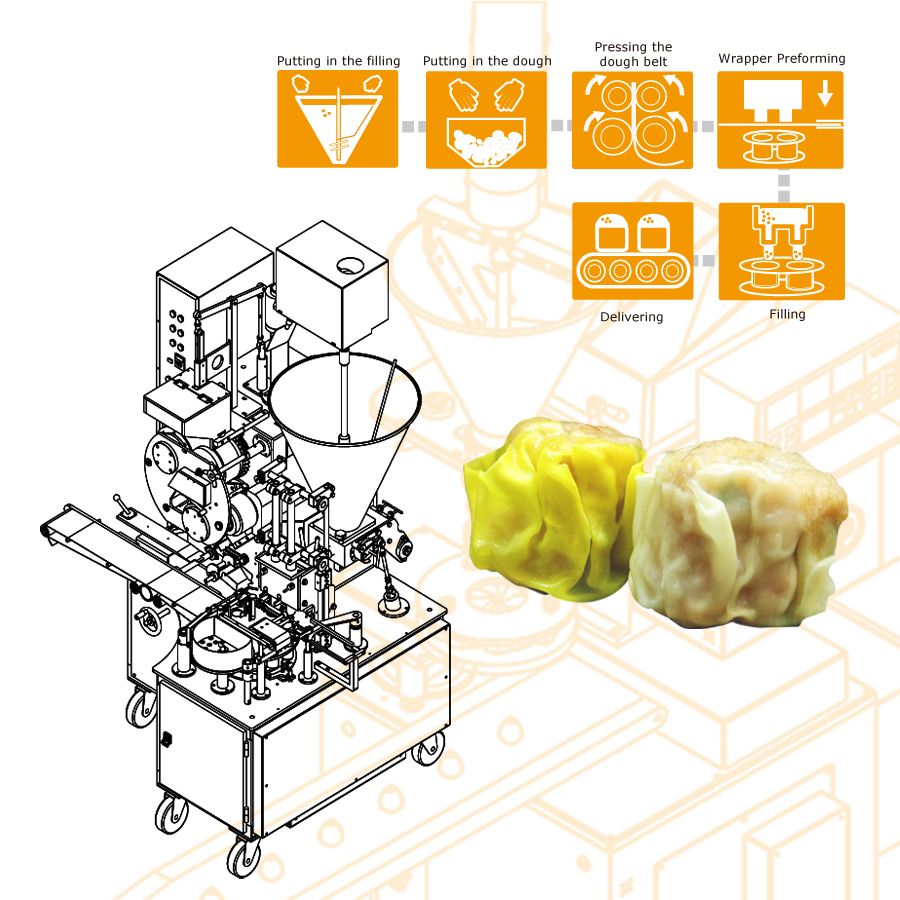

Food Equipment Introduction

- First use ANKO's planetary mixer to stir ingredients to assure all mixtures are well blended.

- Separately place dough and well mixed stuffing in designed hoppers.

- When ready, Shumai (Siomay) processing equipment with a PLC control panel can be started.

- ANKO machine automatically makes dough ball into 0.4-0.5mm thick dough belt.

- This Shumai (Siomay) making process, including dough ball pressing, dough skin cutting, stuffing, forming, delivering, cooling and packaging.

Fundamental of Design

- Food machinery is able to handle large orders and save energy and space at the same time.

- Of course, reasonable price is a must.

- With the effective Shumai (Siomay) production, the restaurant owner in Hong Kong was able to transfer some labors to other production lines, which is a win-win situation.

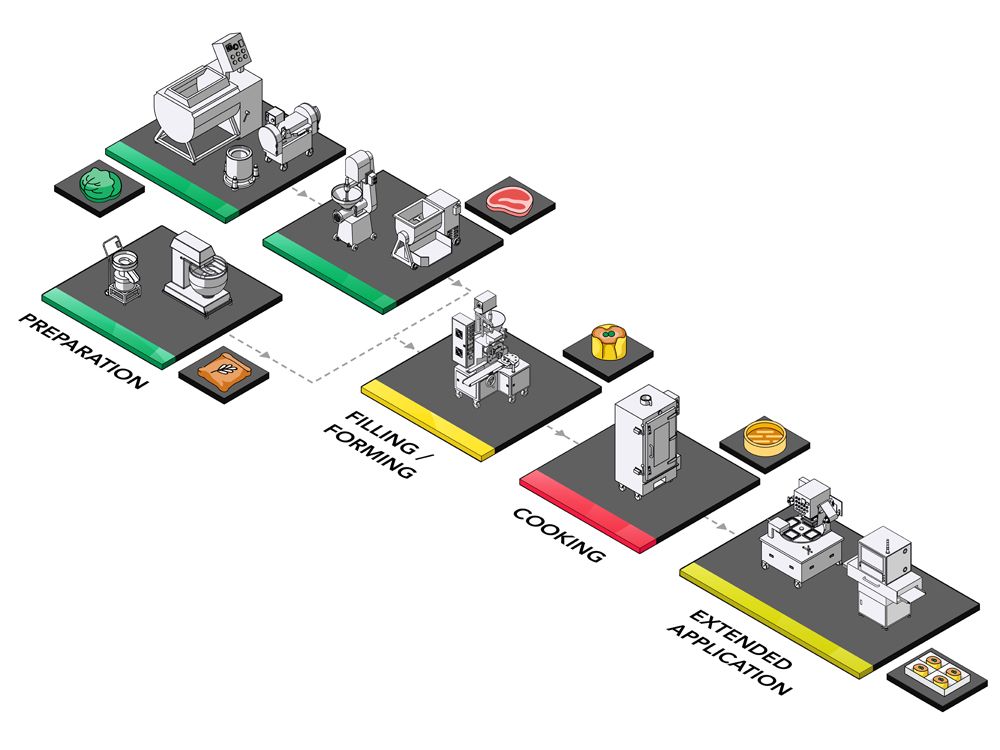

Processing Line Planning

- Sieving

- Mixing

- Vegetable Cleaning

- Vegetable Cutting

- Extracting

- Meat Mincing

- Seasoning

- Forming

- Steaming

- Sealing

- Solution Proposal

-

Automated Process Significantly Enhances Shumai Production and Ensures Consistent Quality

ANKO did

Many Shumai manufacturers and food processing companies have implemented automation equipment for Shumai production to reduce the need for labor and labor costs. Additionally, automation increases production efficiency, allowing for higher Shumai output while maintaining consistent product quality.

ANKO can help you more

ANKO's Automatic Shumai Machine is specifically designed for optimized production. Simply load the hoppers with pre-mixed dough and filling, and the machine can produce wrappers and form high-quality shumai products. We also provide comprehensive "one-stop" services, including front-end and back-end equipment configuration, turnkey project planning, and installation and training for Shumai producers.

For more information, please click Learn More or complete the form below.

- Machines

-

HSM-600

ANKO's HSM-600 automatic Shumai (Siomay) making machine processing line is designed to perform one-stop production. HSM-600 is specialized in produce Shumai (Siomay). Its special filling system can apply wide range of filling types such as beef, pork, shrimp, fish paste(surimi), etc. in order to meet the market needs. For restaurant owners or frozen food suppliers who wish to increase their production capability, HSM-600 is the best choice due to its double line processing which offer high production capacity and save labor costs. Moreover, it can also be customized to produce extra large Shumai (Dim Sim) that are 80g per piece. The built-in IoT system provides remote access to production status and real-time data and error reports to help managers quickly find and resolve problems. It also monitors the machine's health and maintenance schedule to extend its service life.

ML-202E

ML-202E's maximum flour handling capacity is 50kg, and it is ideal for mixing and kneading viscous pastes. It can provide dough balls with proper densities and proportions which is used for general purposes. ML-202E Dough Mixer can be used with wide range of applications, such as kneading the dough, whipping cream, etc.

- Video

- Country

-

-

China

China Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in China with advanced automated food production technology for making Shumai, Har Gow and Dumplings. We also offer integrated solutions for popular foods such as Spring Rolls, Wontons, Stick Gyoza, Baos and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency. Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service. Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

-

- Category

-

- Food Culture

-

Shumai (Siomay) is one of the popular dim sum dishes originated from China. It is provided in Chinese style restaurants where customers would go for breakfast, lunch, dinner or afternoon snacks.

- Handmade Recipe

-

Food Ingredient

For Wrapper-Flour/Egg yolk/Salt/Water/Sugar, For Filling-Fish/Ground meat/Carrot/Spring onion/Seasoning/Corn starch or All-purpose flour

How to make

(1) Put a little water and egg yolk in a bowl with salt and sugar. (2) In a separate bowl, add flour and mixed fluid together. (3) Knead dough until it's not sticky but stretchy. (4) Now let dough ball rest for 30 minutes. (5) To make fish paste, skin off and deboned white fish is advised. Cut into slices. (6) One table spoon of minced carrots and spring onions. (7) One-half cup of corn starch or all purpose flour if you prefer firmer fish paste. (8) Put all ingredients in a mixer. (9) Fish paste is ready when it has become light and sticky after stirring for a minute. (10) Later, use a rolling pin to make Shumai (Siomay) wrapping skin, roll it until it's really thin and cut desired size to wrap fish paste. (11) After it's done, you can eat fish Shumai (Siomay) boiled or deep fried.

- Downloads

-

English

English