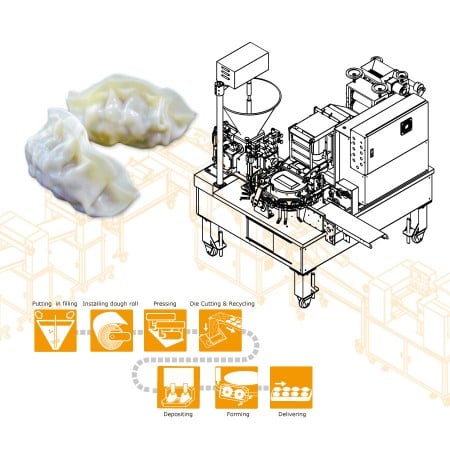

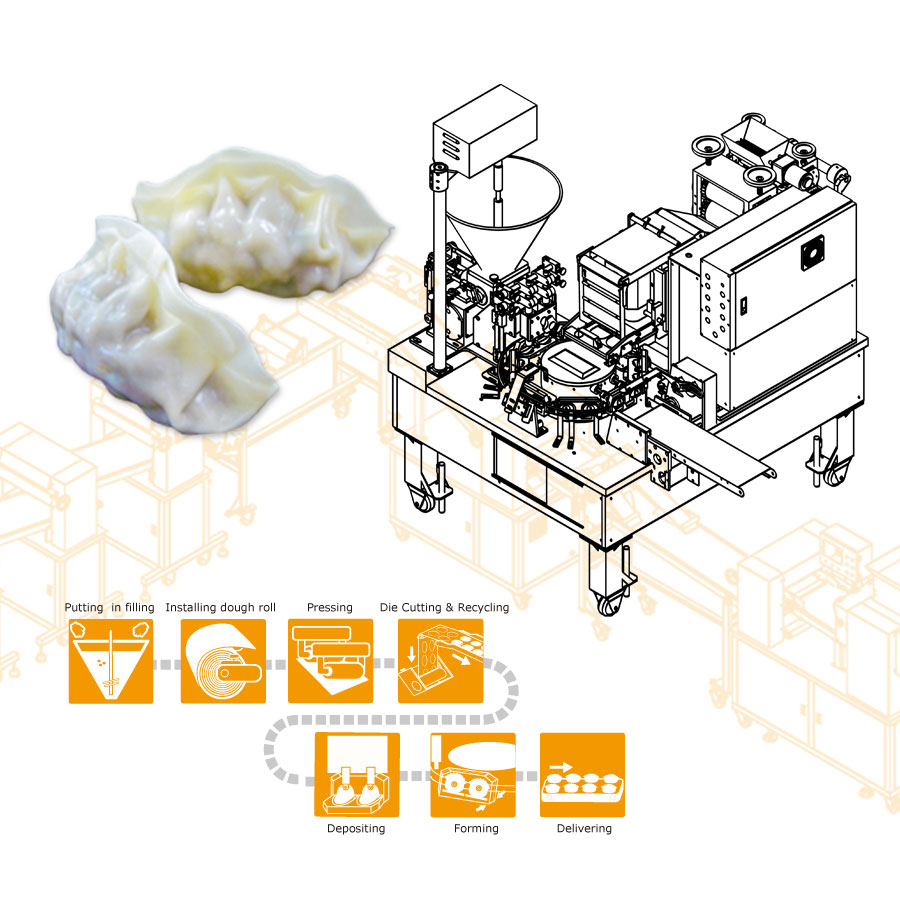

ANKO Chinese Dumpling Industrial Production Line - Machinery Design for an Australian Company

Due to high labor costs and employee management issues, the client, specialized in making Chinese food, started to look for a food processing line for making fried and steamed dumplings. A friend recommended ANKO Food Machine Company to the client. With dumpling making equipment operates automatically, the client is able to increase their production amount with better management. In addition, AFD-888 with CE certificate meets the client's necessary requirement- food safety and hygiene. It is the most important reason that the client chooses ANKO. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

Fried Dumpling, Steamed Dumpling

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Dumpling's Burst Problem

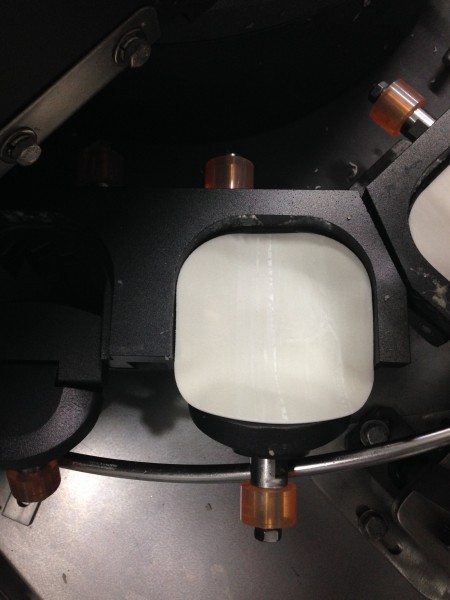

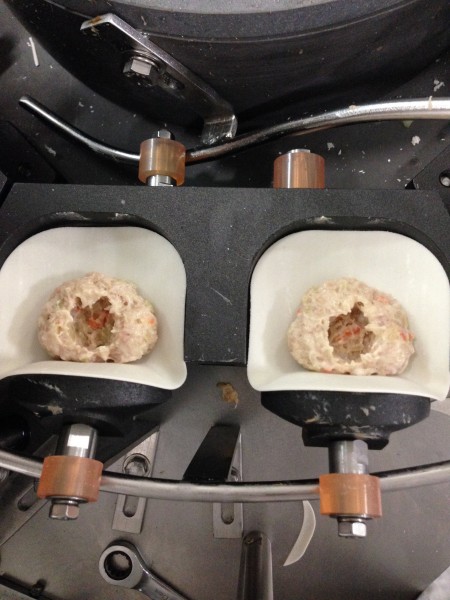

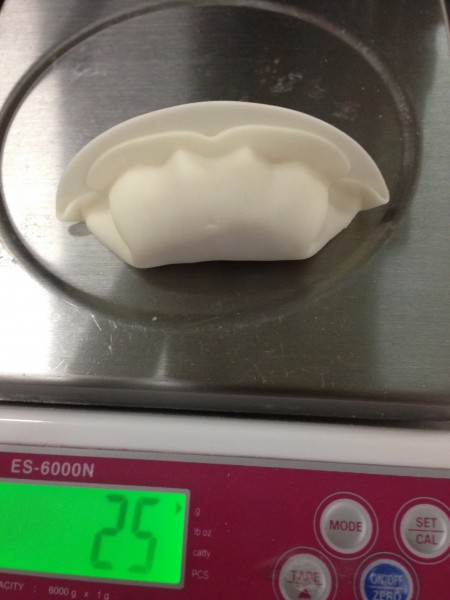

These 25 gram dumplings are wrapped with delicate folds in dough sheets. However, stuffing was bursting out because of too much meat juice. Without changing dumpling's weight, ANKO's R&D team tried to modify its ...(Please contact us to get more information)

Solution 2. Filling Bursting Issue – 25 g and 28 g dumpling mold

When you purchase a dumpling making machine from ANKO, the machine is tested with various ingredients in order to achieve dumpling's perfect texture and consistency. At the beginning, ANKO's engineer tried to use the client's recipe, however, 90% of dumplings' filling burst during processing. Then, our engineer altered the ingredients and solved the problem. We also explained that ingredient ratios would affect finished products, but the client insisted on using the original recipe. Finally, our engineer found a compromising solution without altering the ingredients. Instead of using 25g dumpling mold, ANKO's client decided to switch ...(Please contact us to get more information)

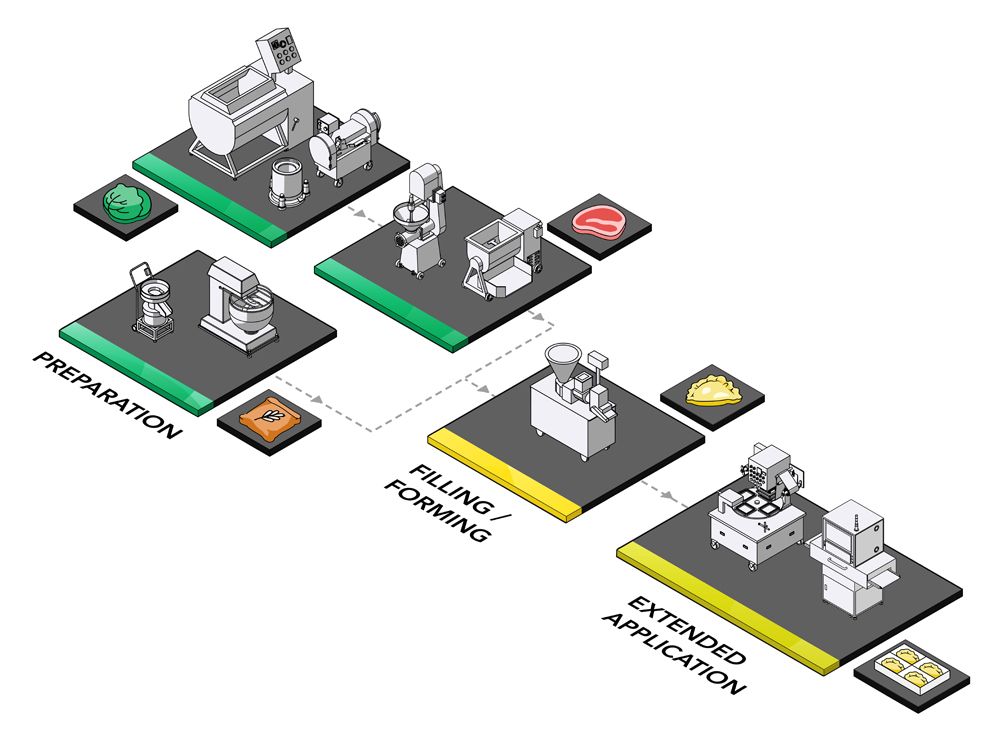

Food Equipment Introduction

- Mix flour, tapioca starch, salt, water, oil in a bowl and stir the mixture. Use ANKO's automatic dough belt making machine to make dough skin with proper thickness.

- For fillings, mix chicken, chopped cabbage and peas together with spices.

- Put dough belt on the conveyer and the ingredient in the feeding hopper to being the process.

Fundamental of Design

- Based on the requirements, the dumpling processing line is designed with fundamental facilities including dough belt maker, feeding hopper, dumpling filling placement, forming and wrapping.

- The fundamental of the design is to build a dumpling production line that is easy to clean, energy-saving and allows making similar foods with great flexibility.

- Dumpling processing equipment can be operated automatically to reduce labor costs.

- The thickness of unbaked dough skin is adjustable (4-12mm).

- The weight of dumpling can be customized.

- The goal of the dumpling making machine is to supply dumplings with 100% handmade texture.

- If the client wants to make fried dumplings, additional food machine can be added.

Processing Line Planning

- Sieving

- Mixing

- Vegetable Cleaning

- Vegetable Cutting

- Extracting

- Meat Mincing

- Seasoning

- Forming

- Sealing

- Solution Proposal

ANKO Dumpling Production Solutions Enhance Efficiency for Food Manufacturers

ANKO did

Traditional handmade dumplings demand a considerable labor force, but the adoption of an Automatic Dumpling Machine can significantly boost production, ranging from 2,000 to an impressive 12,000 pieces per hour. ANKO's HLT-700 series Multipurpose Filling and Forming Machines are expertly designed for dumpling manufacturers, attracting clients worldwide with their advanced technology and unmatched productivity.

ANKO can help you more

With extensive experience in the food industry and professional equipment expertise, ANKO has earned its reputation as a leading brand in food manufacturing. We not only provide state-of-the-art Dumpling Machines for automated dumpling production but also support you in creating a complete Automatic Dumpling Production Line. Our One-stop Dumpling Production Solution encompasses the most suitable front-end and back-end machines, turnkey projects, comprehensive support services, and recipe consultations—all conveniently accessible from a single source. Click Learn More for detailed information.

ANKO has a branch office in California, USA, and a network of agents and distributors in Asia, the Middle East, and Europe, ensuring immediate support. If you're interested in our food solutions, please don't hesitate to contact us or submit an inquiry below.

- Machines

-

AFD-888

ANKO's patented automatic dumpling processing equipment (TW Patent No. I354540, China Patent No. ZL200910140712.2) is designed to make dumplings taste like 100% handmade. AFD-888 dumpling making machine's production capacity is 7,000~9,000 pcs/hr (2 lines) and the size of dumplings can be customized by changing settings in order to meet locals' needs. AFD-888 dumpling making equipment is energy-saving and easy to install when mold or equipment replacement is necessary. (The AFD-888 is no longer available. The replacement model is HLT-700U machine.)

- Video

- Country

Australia

Australia Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Australia with advanced automated food production technology for making Dumplings, Har Gow, and Wonton. We also offer integrated solutions for popular foods such as Empanadas, Spring Rolls, Dim Sum, Samosas, Arancini, Momo, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Dumpling can be cooked by boiling, steaming, simmering, frying, or baking. Sweet or savory. They may be stuffed with meat or vegetable, or there may be other ingredients mixed into the dough.

- Handmade Recipe

-

Food Ingredient

All Purpose Flour/Salt/Water/Tapioca/Oil/Chicken/Cabbage/Peas

Making the Wrapper

(1) Pour flour in the bowl with water and salt, stir until it gets sticky. (2) Sprinkle some flour on a table before starting dough skin making process. (3) Grab the dough ball from the bowl, roll it out and make it long. (4) Cut dough into small pieces; roll them out using a rolling pin.

Making the Filling

(1) Mince chicken and slice cabbage. (2) Mix chicken, cabbage, and peas together. (3) Grab a small amount of filling, place it in the middle of a skin. (4) Put a little bit of water around edges for folding the skin. (5) Pinch and tuck floury skin to shape dumpling. (6) Once raw dumplings are made, you can start cooking them depending on how you want to eat them. They can be eaten in soups or stews, with gravy, or in any other ways – boiled, steamed or fried.

English

English