ANKO Customized a Har Gow Machine and Provided Production Solutions for a Client in Hong Kong

The client begins business by manufacturing seasoning. Up to now, the company has been established for more than one hundred years, providing delicious, health, and safety food to gourmets. Since their dim sum products are on the market in 1990, they have applied ANKO's stir fryers (SF Series), dumpling making machines (HLT-700 Series), spring roll production line (SR-24), semi-automatic spring roll production line (SRPF Series) to produce and sale frozen foods, including Chinese fried rice/noodle and various kinds of dim sum, in many countries. With the growth of demands, the supply of Har Gow (Shrimp dumpling), made by hand, was unable to meet a large number of orders. This client still purchased an automatic dumpling machine with Har Gow (Shrimp dumpling) forming device from ANKO because they believe in our machine quality, which achieves the client's ideas with regard to strictly maintaining sanitary environment, controlling every production process, and providing the safest food to consumers.

Har Gow (Shrimp dumpling)

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Customized Har Gow Mold and Production Solutions

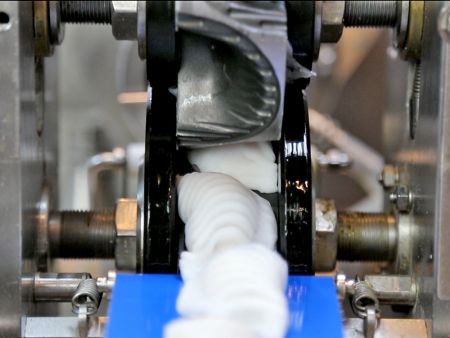

ANKO’s client requested customized Har Gow molds that are made for producing dumplings that are 36g per piece, which is larger than the standard Har Gow mold. While doing so, ANKO’s engineers tested and adjusted our “pleat forming kit” with a new mold in order to produce high quality larger Har Gow with more efficiency. ANKO has more than 48 years of experience in the automated food production equipment industry, and our professional teams are ready to create customized machines along with providing production solutions to make your food business more successful.

The unique pleats were formed using our new pleat forming kit, and the final product turned out perfectly

Solution 2. What the reasons lead to breaks on the bottom of Har Gow?

The ingredients of Har Gow wrapper and dumpling wrapper are different from each other. When the stuffed dough roll extruded out, Har Gow wrappers would break because of the friction between Har Gow wrappers and the guide plate prior to the forming mold, whereas smooth dumpling wrapper was intact. In order to solve the problem, ANKO's engineers designed...(Please contact us to get more information)

ANKO assisted a client with fine tuning their Har Gow production process in order to make perfectly formed Shrimp Dumplings. This client sorted their Har Gow by hand prior to packaging; however, ANKO can also suggest compatible automated packaging and sealing machines to create a more efficient production line.

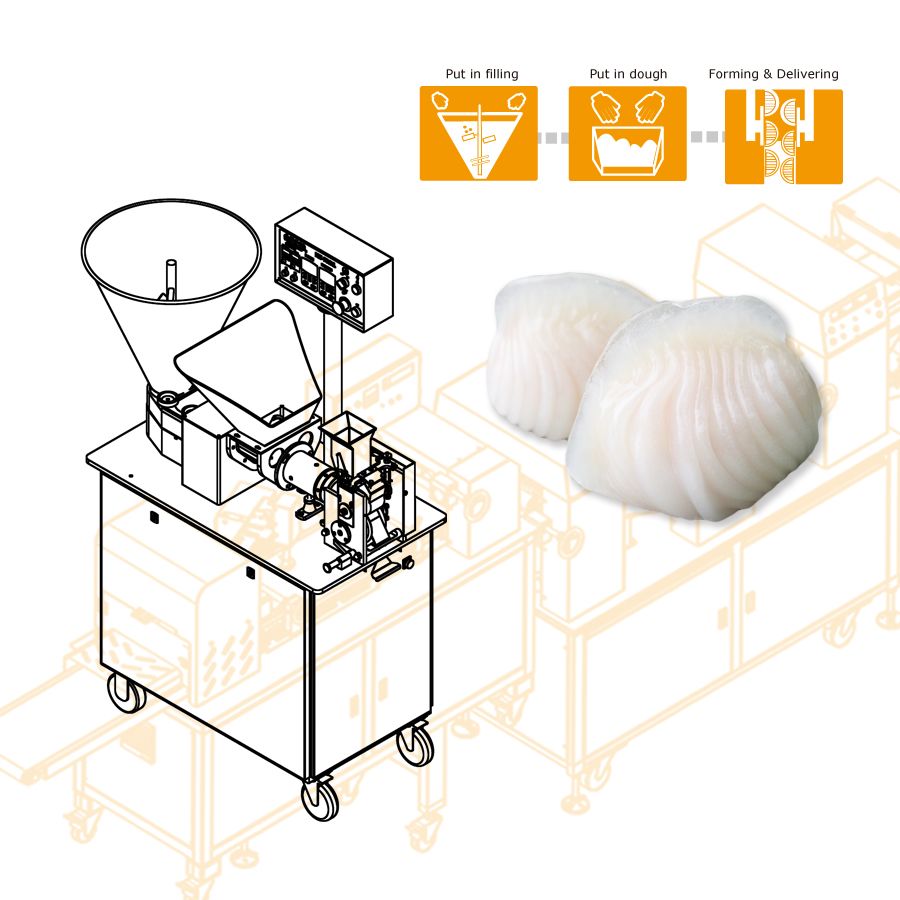

Food Equipment Introduction

- Put stuffing in stuffing hopper

- Put dough in dough hopper

- Stuffing is formed into a cylinder through feeding pipe.

- Dough is formed into a tube through dough pipe.

- While stuffing and dough are formed, stuff is extruded into dough pipe.

- Make pleats by Har Gow forming device.

- Through forming mold, form every piece of Har Gow as required.

- Remove Har Gow from mold by scraper.

- The final products line on conveyor for following packing or cooking process.

Fundamentals of Har Gow Processing Design

The Har Gow making machine is the combination of the HLT-700 series and Har Gow forming device. The iconic pleated skin is the reason that we re-design dough pipe for pleating, but the production process is as same as HLT-700 Series. The standard size of Har Gow made by our machine is between 20g to 30g. However, like the flexibility of HLT-700 Series, Har Gow forming device can be customized for making various sizes to meet individual requirements. For example, we customized a mold for making 40-gram Har Gow for a client.

- Solution Proposal

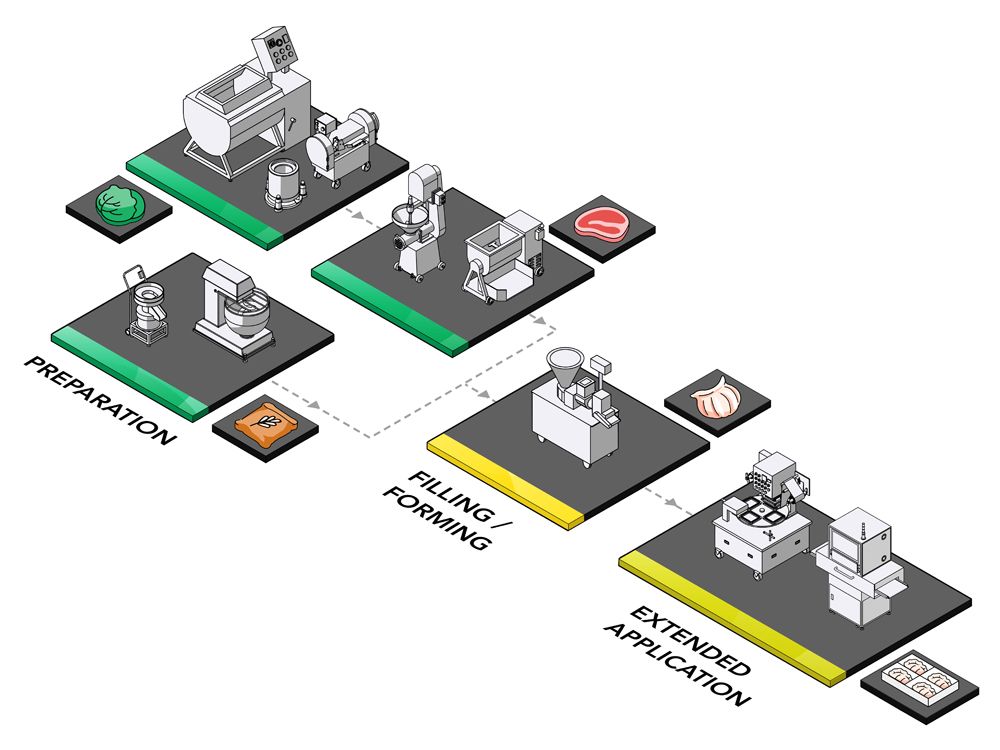

Fully Integrated Automatic Production Solution for Har Gow

ANKO did

ANKO's Har Gow Machine And Production Solution can help you produce Har Gow from manual production to automated manufacturing without sacrificing the original flavors and quality. Standard and customized forming molds are available for you to meet your specific requirement.

ANKO can help you more

Both HLT-700U and HLT-700XL machines are the key filling and forming machines to produce Har Gow. Besides, ANKO can also provide the front-end and back-end machines to set up a highly efficient One-stop Har Gow Production Line. This would not only reduce the operators but would also save the training cost for food business companies.

If you’re interested in more information about our Har Gow Production Solution, please click Learn More or feel free to fill out the form below, and we will get back to you as soon as possible.

- Machines

-

HLT-700 Series with Har Gow Forming Device

HLT-700 series with Har Gow Forming Device extrudes dough tube with filling stuffed. Through our innovative Har Gow forming device, the typical pleats of Har Gow are forming while dough and filling are extruded. Then, the stuffed roll will be pressed by a forming mold to form a beautiful Har Gow. There are three standard molds for producing 20g, 25g, or 30g Har Gow. Also, the forming mold is available to customize different shapes. More importantly, the Built-in IoT System can be overseen by production management in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making.

- Video

ANKO’s HLT-700XL is the best automated food machine for making Har Gow; it can produce 2,000 to 10,000 pieces per hour. It only requires loading the hoppers with premixed dough and shrimp filling, selecting the desired Har Gow mold and parameter settings, and the ANKO machine will take care of the rest. This machine can process shrimp pieces as large as 8x30mm, and ANKO can also provide customized Har Gow molds upon request.

- Country

Hong Kong

Hong Kong Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Hong Kong with advanced automated food production technology for making Har Gow, Tang Yuan, and Glutinous Rice Ball (Mochi). We also offer integrated solutions for popular foods such as Dumplings, Shumai, Wonton, Dim Sum, Meatballs, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Har Gow (Shrimp dumpling) is beloved of most consumers as having dim sum in tea restaurants or Cantonese restaurants. Translucent wrapper made of wheat starch wraps up chopped shrimp and minced pork fatback. Also, due to its clear, bright pleated skin, some people name Har Gow crystal dumpling. Fresh shrimp, elastic wrapper, and juicy stuffing, the relish of Har Gow satisfies people's gustatory sense. Sometimes, a mouthful of Har Gow with a whole shrimp is even more surprising. Soy sauce is the most common dip, but some gourmands taste with shredded ginger like the way of tasting mini juicy buns.

- Handmade Recipe

-

Food Ingredient

For wrapper-Wheat Starch/Potato Starch/Hot Water, For filling-Shrimp/Bamboo Shoots/Ground Pork Fatback/Scallions/Salt/Stock Powder/Sugar/Sesame Oil/White Pepper

Making the filling

(1) Heat oil in a wok. (2) Sauté chopped scallions until aromatic, and then fry ground pork fatback together. (3) Set aside. Chop shrimp and bamboo shoot. (4) Season and stir chopped shrimp and bamboo with salt, white pepper, sugar, stock powder, and sesame oil until viscous.

Making the wrapper

(1) Mix wheat starch and potato starch together. (2) Pour in hot water and stir them again. (3) Cool it for a while, and then knead it into smooth dough. While kneading, add a little potato starch. (4) Roll the dough into a cylinder. (5) Cut off several dough balls around 6 g. Cover the rest of dough with cling film to avoid it drying out. (6) Apply a cleaver. Use the flat side to press dough ball into a circle. A half of circle can be thicker than the other half side as the bottom of Har Gow.

How to make

(1) Scoop filling to put on the center of wrapper. (2) Fold it up, and then pleat the edge to make patterns, around nine to twelve pleats for each. (3) Steam Har Gow for four to five minutes with high heat.

- Downloads

English

English