Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

An ANKO client operates restaurants and takeout shops in Australia; they also own a food factory and sell their products in supermarkets. Their food items include Har Gow (Shrimp dumplings), Tang Baos, Dumplings, and Buns. Recently, many food businesses have started using automated production equipment due to labor shortages in Australia. This client is a great example. They purchased ANKO’s HLT-700XL Multipurpose Filling And Forming Machine, EA-100KA Forming Machine, SD-97SS Automatic Encrusting And Forming Machine, and other ANKO machines to produce a wide range of products. They successfully transitioned to automated food production, increased productivity, and resolved labor issues. ANKO’s engineers helped the client maintain the machines and develop new Har Gow flavors successfully.

This customer's factory is in California which has the largest population of Chinese people in the United States. They specialize in the manufacturing and wholesaling of Chinese food including Dumplings, Har Gow, Baozi, Spring Rolls, Shumai, etc. They have a distribution center in their local area, and consumers can buy their products in supermarkets, direct wholesale, and from other distributors. This customer owns ANKO’s HLT-700XL Multifunctional Filling and Forming machine, SD-97W Automatic Dumpling Machine, HSM-600 Automatic Shumai Machine, and the SRP Automatic Spring Roll Pastry sheet machine. As the demand for spring rolls has continued to increase, the customer learned about ANKO's latest SR-27 Spring Roll Machine and they immediately contacted us to arrange a demonstration. In addition to the vegetable and pork Spring Rolls the customer originally produced, they requested to test run using cheese and apple cinnamon fillings because of their desire to develop innovative new Spring Roll products and capitalize on the growing Sweet Spring Roll market.

This client is a pioneer in introducing Chinese Dim Sum for European markets; they started producing and selling premade frozen Dim Sum products to many different wholesale and retail stores in Europe and accomplished great brand recognition. However, considering the high labor costs in most European countries, this client approached ANKO for an automated production assessment. In order for their business to improve and expand they decided to purchase ANKO’s HSM-600 Siumai Machine; soon after this purchase the client returned to ANKO and purchased ANKO’s HLT-700XL Multipurpose Filling and Forming Machine for producing Har Gow (Shrimp dumplings). The purchase of both ANKO machines helped them accomplish their production requirements and meet market demands.

An ANKO client operates a baking factory in the Netherlands and exports their baked goods to various European countries, including the UK, France, Germany, and Luxembourg. Recently, this client ventured into the production of Chinese Dim Sum and learned about ANKO through local food industry contacts. Due to our excellent reputation, professional expertise and quality service in the industry, we successfully created an automated Har Gow production line for making high-quality Har Gow that met the client’s expectations.

The client begins business by manufacturing seasoning. Up to now, the company has been established for more than one hundred years, providing delicious, health, and safety food to gourmets. Since their dim sum products are on the market in 1990, they have applied ANKO's stir fryers (SF Series), dumpling making machines (HLT-700 Series), spring roll production line (SR-24), semi-automatic spring roll production line (SRPF Series) to produce and sale frozen foods, including Chinese fried rice/noodle and various kinds of dim sum, in many countries. With the growth of demands, the supply of Har Gow (Shrimp dumpling), made by hand, was unable to meet a large number of orders. This client still purchased an automatic dumpling machine with Har Gow (Shrimp dumpling) forming device from ANKO because they believe in our machine quality, which achieves the client's ideas with regard to strictly maintaining sanitary environment, controlling every production process, and providing the safest food to consumers.

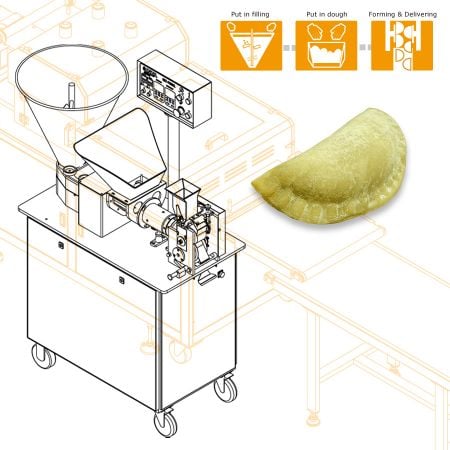

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors and got great comments on some travel websites. The calzone, both its recipe and ingredients, is handmade by their chef. As spending holidays in the hotel, tourists can buy a portable calzone at a concession stand and enjoy it as leisurely walking around. Due to the widespread reputation of the dish, they decided to buy a machine to meet the growing demand or the future launch of new menu in their restaurants. Then, the gourmet calzones could be produced in their central kitchen and distributed to each restaurant, which not only maintains product quality, but also cuts the labor cost.

The client operates an air catering company. They offer airline meals to many flights for serving tens of thousands of passengers who travel in and out of China. Shrimp dumpling is an exquisite dish just for business and first class passengers. Due to its complex procedure, rising wages in China, and growing demand, they decided to automate the production of shrimp dumpling. ANKO's Automatic Har Gow Forming Machine manufactures 2,000 pieces per hour and delivers standardized quality control, stable production, simple maintenance and care. They are key factors that contribute to the cooperation.