Automatic Har Gow Forming Machine - Machinery Design for a Chinese Company

The client operates an air catering company. They offer airline meals to many flights for serving tens of thousands of passengers who travel in and out of China. Shrimp dumpling is an exquisite dish just for business and first class passengers. Due to its complex procedure, rising wages in China, and growing demand, they decided to automate the production of shrimp dumpling. ANKO's Automatic Har Gow Forming Machine manufactures 2,000 pieces per hour and delivers standardized quality control, stable production, simple maintenance and care. They are key factors that contribute to the cooperation.

Shrimp Dumpling

ANKO Team Research Problem Solving or Solution Delivery

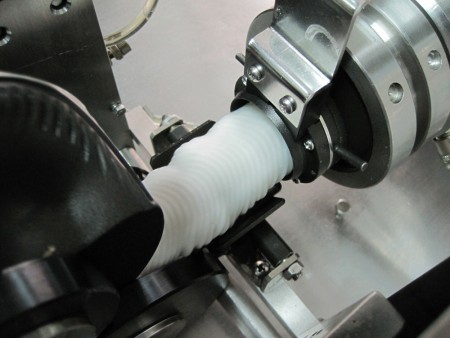

The determinant of forming pleats on shrimp dumpling

As the dough tube is extruded, it has invisible curves, instead of straight extrusion. In order to form classic pleats,....(Please contact us to get more information)

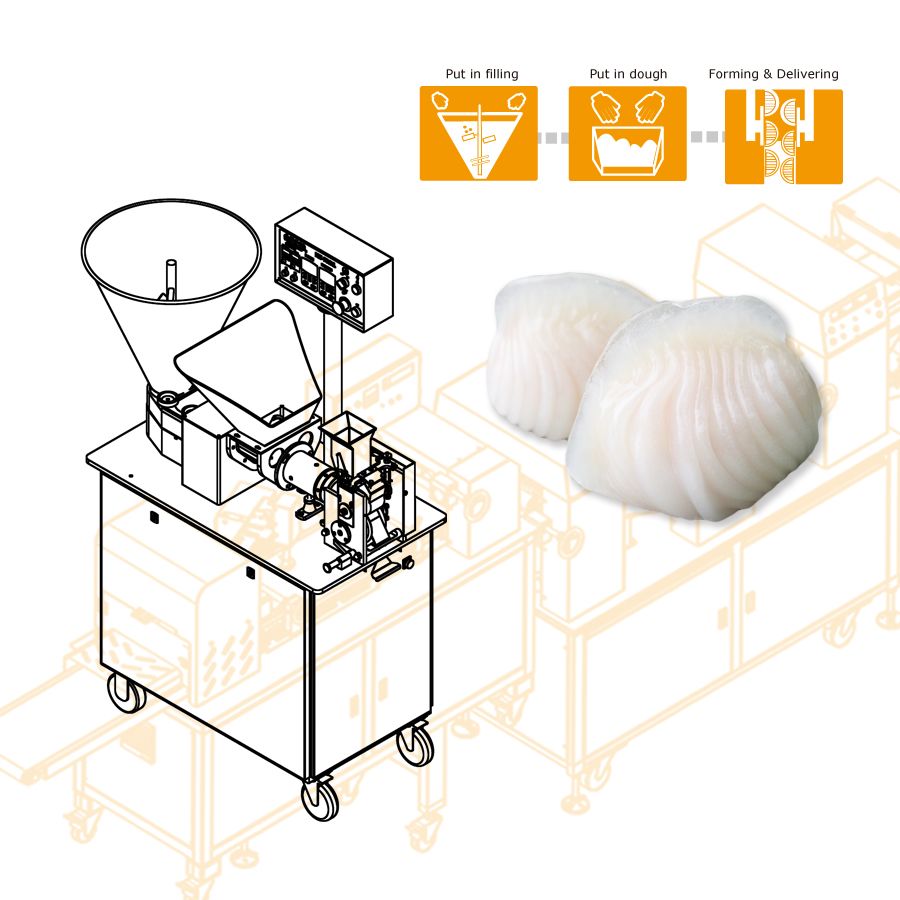

Put stuffing and dough into HLT-700 series hoppers and then turn on the machine to produce crystal shrimp dumpling. Operators only have to manually align final products on pans for the next cooking or packing process.

Food Equipment Introduction

- Pour stuffing into stuffing hopper to squeeze out air from the hopper first.

- Put dough in dough tank. After extruding dough tube, adjust wrap thickness as required.

- Forms stuffing into cylinder through stuffing pipe.

- Fill the cylindrical stuffing into the dough tube while both are formed.

- Make pleats through har gow forming device.

- Form product shape by the pressure of forming mold.

- Remove shrimp dumpling from mold by a scraper.

- The final products are lined on conveyor for following packing or cooking process.

How to solve the problem of tearing dough wrapper.

After extruding, the stuffed tube passes through a dough supporting plate. Generally speaking, products with a smooth surface such as traditional dumpling can be delivered into the forming mold. However, shrimp dumpling made from wheat starch dough is torn by friction. Therefore, ANKO engineer replaced ....(Please contact us to get more information)

- Solution Proposal

Efficient Har Gao Production Enables Food Businesses to Increase Sales

ANKO did

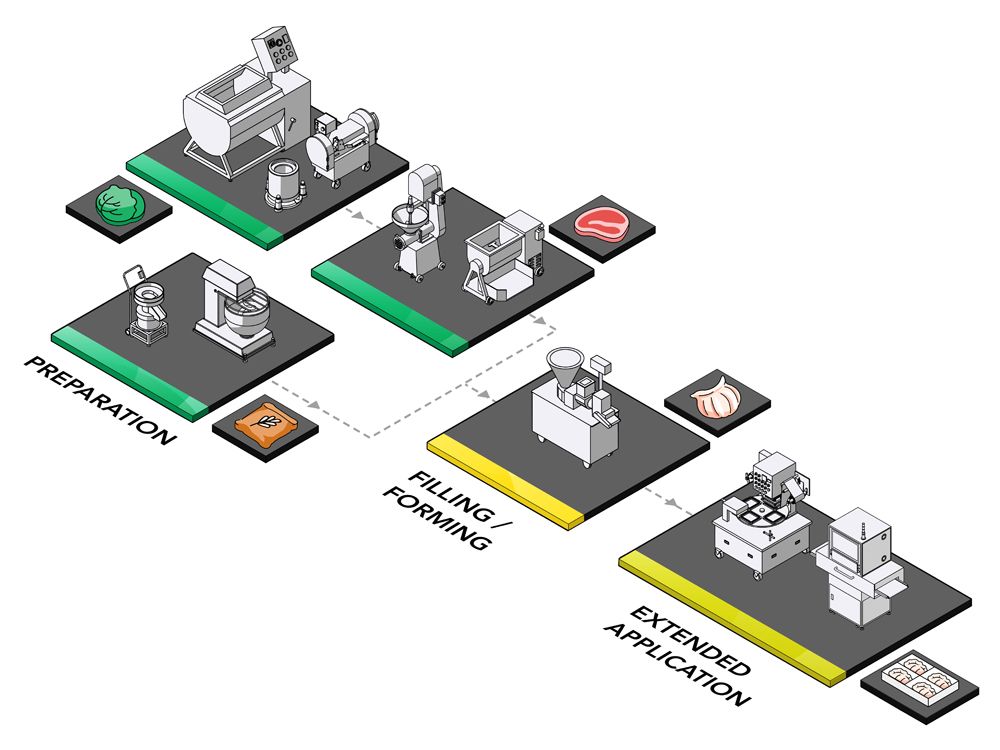

The best way for dealing with a shortage of labor in food manufacturing is switching to automate existing operations. It is known that handmade har gao takes a lot of time. Beginning with making the har gao dough, filling, then assemble one by one. Using food processing equipment to grow your har gao business is efficient, smart and fast solution.

ANKO can help you more

Today, in the food industry, a Multipurpose Filling And Forming Machine can process from dough to forming which improved har gao's productivity and automation can free up laborers, who can be re-trained for other positions. ANKO's One-stop Har Gao Production Solution can benefit large food factories, central kitchens and high volume producers to speed up the process from front-end to back-end.

If you’re interested in more information, please click Learn More or feel free to fill out the form below, and we will get back to you as soon as possible.

- Machines

-

HLT-700 series Multipurpose Filling & Forming Machine and Har Gow Forming Device

The har gow forming machine is the combination of HLT-700 series Multipurpose Filling & Forming Machine and Har Gow Forming Device. First of all, wheat starch dough is extruded into a tube, and then filled in shrimp stuffing. Next, through the har gow forming device, a stuffed tube is pleated typical crimps. Finally, it is pressed into pieces by a forming mold. Also, depending on client's product weight, molds for making 20 g, 25 g, or 30 g of shrimp dumpling are customizable. More importantly, the Built-in IoT System can be overseen by production management in real time on a mobile device, and the data can be collected and processed through Big Data Analytics to support decision making.

- Country

China

China Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in China with advanced automated food production technology for making Shumai, Har Gow and Dumplings. We also offer integrated solutions for popular foods such as Spring Rolls, Wontons, Stick Gyoza, Baos and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Shrimp dumpling is beloved of most consumers as having dim sum in tea restaurants or Cantonese restaurants. Translucent wrapper made of wheat starch wraps up chopped shrimp and minced pork. Also, due to its clear, bright pleated skin, some people name it crystal dumpling. Fresh shrimp, tenderly chewy wrapper, and juicy stuffing, the relish of shrimp dumpling satisfies people's gustatory sense. Soy sauce is the most common dip, but some gourmands taste with shredded ginger like the way people taste mini juicy buns.

- Handmade Recipe

-

Food Ingredient

For wrapper-Wheat Starch/Potato Starch/Hot Water, For filling-Shrimp/Bamboo Shoots/Ground Pork Fatback/Scallions/Salt/Stock Powder/Sugar/Sesame Oil/White Pepper

Making the filling

(1) Heat oil in a wok. (2) Saute chopped scallions until aromatic, and then fry ground pork fatback together. Set aside. (3) Chop shrimp and bamboo shoot. (4) Season and stir chopped shrimp and bamboo with salt, white pepper, sugar, stock powder, and sesame oil until viscous.

Making the wrapper

(1) Mix wheat starch and potato starch together. (2) Pour in hot water and stir them again. (3) Cool it for a while, and then knead it into smooth dough. While kneading, add a little potato starch. (4) Roll the dough into a cylinder. (5) Cut off several dough balls around 6 g. Cover the rest of dough with cling film to avoid it drying out. (6) Apply a cleaver. Use the flat side to press dough ball into a circle. A half of circle can be thicker than the other half side as the bottom of har gow.

How to make

(1) Scoop filling to put on the center of wrapper. (2) Fold it up, and then pleat the edge to make patterns, around nine to twelve pleats for each. (3) Steam har gows for four to five minutes with high heat.

- Downloads

English

English