ANKO Created Filling Solutions for a Tunisian Client to make 150g super-sized Calzones

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors and got great comments on some travel websites. The calzone, both its recipe and ingredients, is handmade by their chef. As spending holidays in the hotel, tourists can buy a portable calzone at a concession stand and enjoy it as leisurely walking around. Due to the widespread reputation of the dish, they decided to buy a machine to meet the growing demand or the future launch of new menu in their restaurants. Then, the gourmet calzones could be produced in their central kitchen and distributed to each restaurant, which not only maintains product quality, but also cuts the labor cost.

Calzone

ANKO Team Research Problem Solving or Solution Delivery

Calzone stuffing is too dry to be extruded.

The client fried stuffing in advance, as a result, the stuffing became too dry to be extruded smoothly. In this case, we asked the client ...(Please contact us to get more information)

Finally, we produced the 150g super-sized Calzone, and the client was satisfied with both the production and textures.

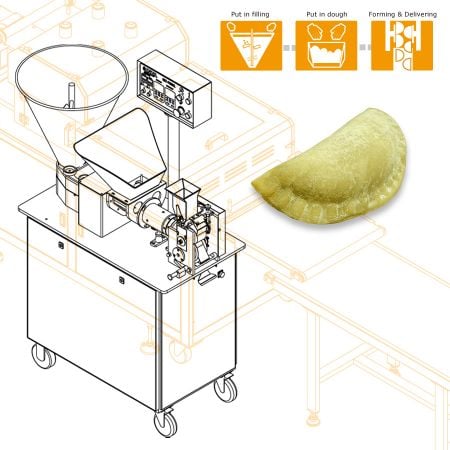

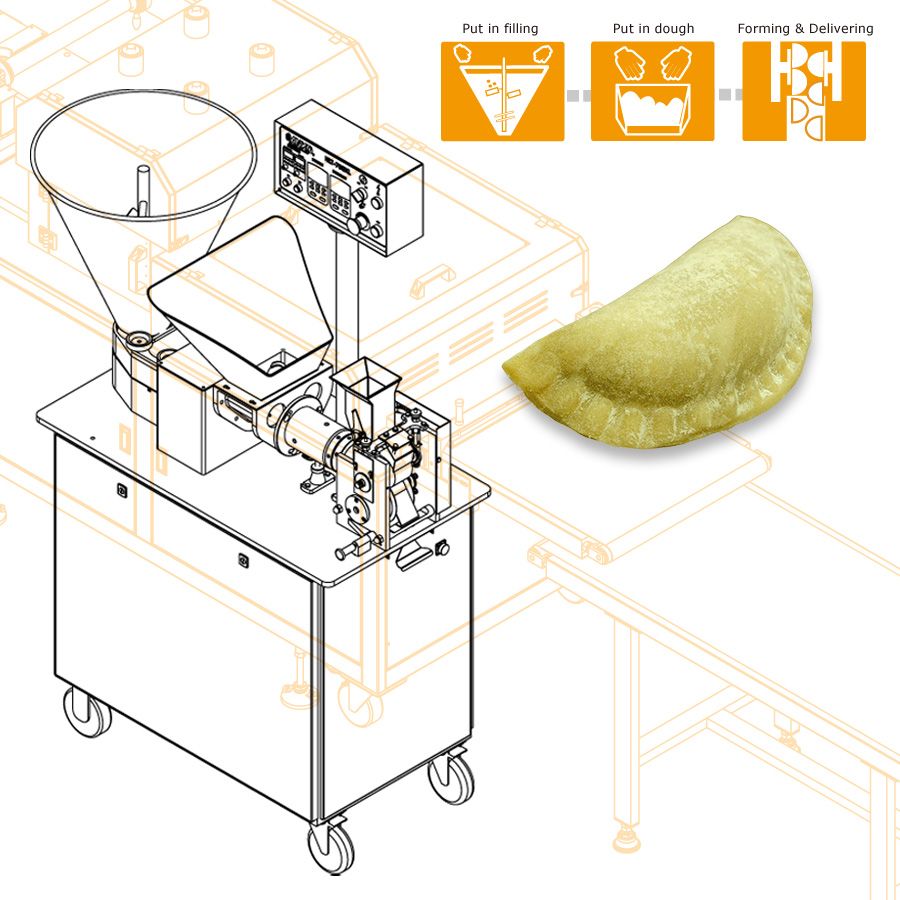

Food Equipment Introduction

- Put well-mixed stuffing in stuffing hopper.

- Put well-kneaded dough in dough hopper.

- Stuffing is extruded into a cylinder through stuffing pipe.

- Dough is extruded into a tube through dough pipe.

- While both cylindrical stuffing and dough tube are formed, stuffing is extruded into the dough tube.

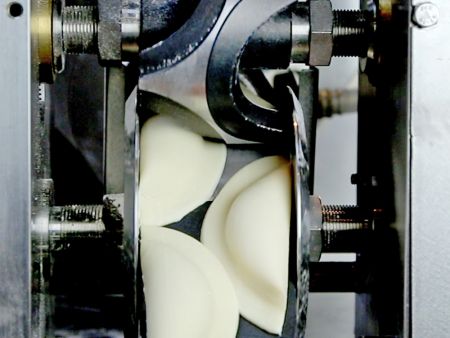

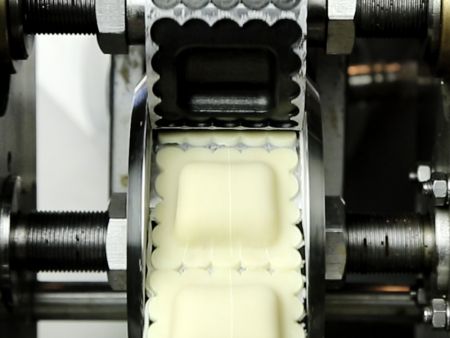

- With the pressure of forming mold, the stuffed dough tube is formed into the food shape as required.

- The use of scraper helps release food products from the mold.

- Arrange finished products on conveyor for the sequential baking process.

In the production of calzone, controlling the dough temperature properly can ensure the stable production.

The temperature increases while machine presses dough, which may lead to too soft and sticky dough. ANKO's HLT-series machine is equipped with a cooling system to maintain dough pipe in a certain temperature to guarantee the best taste. The cooling system is considerately designed a light to remind workers to refill iced water, helping to save checking time.

The design basics of custom mold

ANKO's Multipurpose Filling & Forming Machine facilitates great product variety through changeable mold. Due to a huge demand for customization, our engineers continue enhancing the ability of mold design. In terms of forming mold, the pattern is carved along the rims of hollow parts. With its pressure as rotating, dough is squeezed into hollow parts and formed.

- Solution Proposal

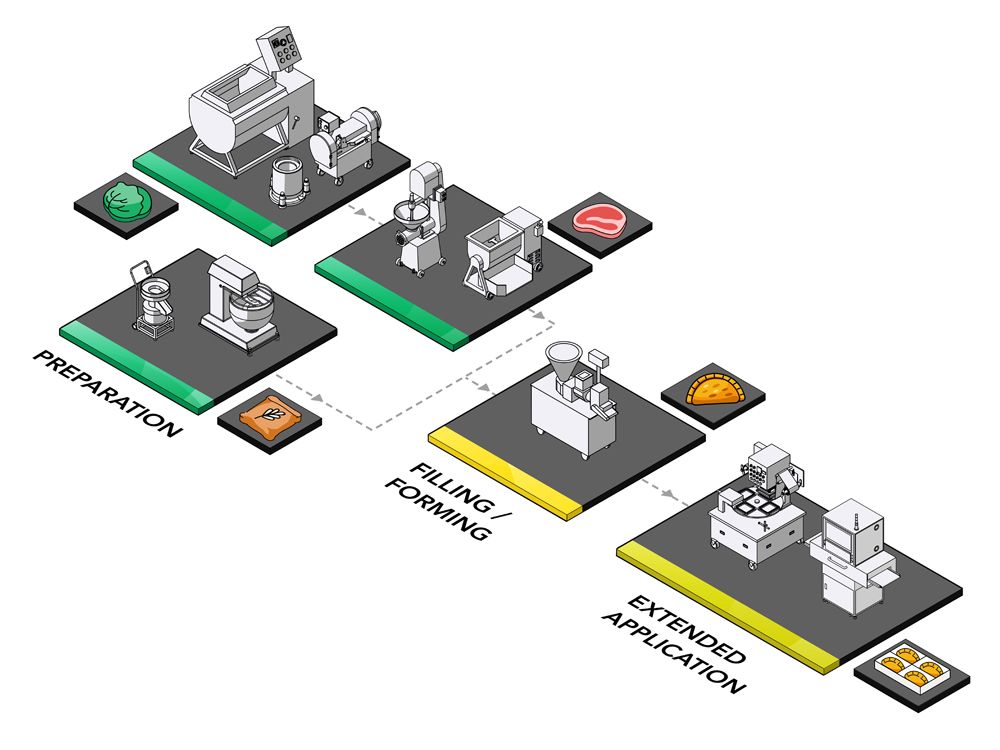

Make Calzone Production More Efficient with ANKO's One-stop Solution

ANKO did

In this case, the client purchased HLT-700XL Multipurpose Filling And Forming Machine for making Calzone. The capacity is 2,000 to 10,000 pcs in one hour. There are still two options for making Calzone, one is HLT-700U with an IoT system and the other is HLT-700DL double line machine.

ANKO can help you more

In addition to forming machines, ANKO can also offer front-end to back-end equipment, such as vegetable cutter, dough mixer, packing machine, food X-ray inspection machine, etc, for you to build a highly efficient Calzone Production Line.

If you are interested in more information, please click Learn More or fill out the inquiry form below.

- Machines

-

HLT-700XL

Simply put well-kneaded dough into the dough hopper. Dough is extruded into a dough tube and filled in stuffing. In this case, the client chose 150g and 200g mold to produce calzone. The maximum capacity is 1,800 pcs per hour. ANKO is a pioneer in the food machinery industry, and we have upgraded our “HLT-700XL Multipurpose Filling and Forming Machine” to include a built-in Internet of Things (IoT) system to provide real-time access to data monitoring to manage production better remotely. It can automatically detect any parts that require maintenance and sends alerts to lower risks and repair costs while giving you more time to focus on food production.

- Video

ANKO's HLT-700XL is a kind of dumpling making machine. It has four independent motors to produce a wide range of food products with a dough wrapper and stuffing inside. By simply changing the forming molds, HLT-700XL can also become different food processing machines as har gow machine, samosa machine, ravioli machine, pasta machine, pierogi machine, pelmeni machine, calzone machine, empanada machine, etc.

- Country

Tunisia

Tunisia Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Tunisia with advanced automated food production technology for making super-sized Calzones. We also offer integrated solutions for popular foods such as Maamouls, Cookies, Kibbehs, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Calzone, or pizza pocket, is often served in Italian restaurants, also a popular dish in North Africa and Middle East. The name calzone derives from "calze", meaning stocking. It is a kind of portable stuffed bread with a half-moon shape. Generally, calzone is stuffed with minced meat, vegetable, cheese, and tomato and mushroom calzone is optional for vegetarian. Final product weighs between 150 g to 250 g to keep you feeling satisfied.

- Handmade Recipe

-

Food Ingredient

For wrapper-Strong Flour/Salt/Warm Water/Yeast/Sugar/Oil, For filling-Oil/Mushrooms/Garlic/Fresh Thyme/Unsalted Butter/Ground Black Pepper/Tomato Sauce/Spinach/Mozzarella Cheese/Salami/Ham

Making the wrapper

(1) Mix flour and salt in a bowl. (2) Add warm water, yeast, sugar, and oil in the bowl, stir them until dough forms. (3) Cover with a damp towel and rest for 1 hour in a warm place.

Making the filling

(1) Chop mushrooms and slice garlic. (2) Heat oil in a skillet. (3) Add mushrooms, garlic, and thyme in; fry them until mushrooms are softened. (4) Add butter and then season with salt and pepper. (5) Add tomato sauce and spinach, cook about 3 minutes.

How to make

(1) Portion out the dough into equal size dough balls. (2) Roll out into circles, about 1/8 inch thick and 12 inches in diameter. (3) Place spinach and mushroom mixture in the lower half of the dough, but leave the edge about 1-1.5 cm for folding. (4) Top with slices of salami and ham. (5) Top mixture with mozzarella cheese. (6) Fold dough in half over filling. (7) Seal and crimp the edge. (8) Bake calzones until golden brown.

- Downloads

English

English