Kubba Mosul Pastry Production Line -Machinery Design for Jordanian Company

The manual production of Kubba Mosul Pastry relies on a large amount of labor. The ingredients for making pastry and filling must be prepared separately; in addition, shaping a flat circle takes complex steps. Many Middle Eastern immigrants in western countries cannot forget the taste of hometown. Therefore, the market not only in Middle East but also in western countries, there have been marked growing needs for the manufacture of many Kubba Mosul products. A lot of clients hoped to have an automatic Kubba Mosul machine, so that ANKO has kept that in mind and carried out the new project development.

Kubba Mosul Pastry

ANKO Team Research Problem Solving or Solution Delivery

The viscosity of Kubba Mosul led to the difficulty in positioning and quantitative depositing patties.

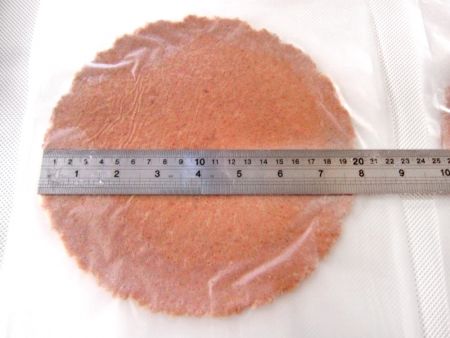

Fine bulgur, one of ingredients of Kubba Mosul, increases viscosity after mixing with water and meat paste is also sticky. The natures of the foods resulted in unstable depositing and inaccurate position. In the stage of research and development, our R&D engineers focused on non-sticky design. They found that the solution was not only to use non-sticky molds, but also to create an innovative machine structure and an air blow system. ANKO's Kubba Mosul Pastry Production Line boasts the unique depositing unit to maintain the traditional taste of Middle-Eastern food and achieve the needs of automated production without comprising clients' recipes.

ANKO collaborates with our agents in the Middle East to provide authentic and tailor-made Kubba Mosul recipes. These recipes incorporate local ingredients specifically for consumers in this regional market; we also offer professional after-sales services. ANKO ensure the products will meet the specific requirements for countries such as Iraq, the Syrian Arab Republic, Israel, Jordan, Lebanon, and Saudi Arabia. We proudly provide full customer support and services to all our clients.

Food Equipment Introduction

- Prepare mixture for Kubba Mosul Pastry production.

- Deposit meat patties on film as preset size in position.

- Cover patties with plastic film and convey them to pressing unit.

- Film puller regularly pull films forward a set distance

- Pre-pressed by the first row of pressing plates.

- Tightly pressed by the second row of pressing plates.

- Cut each piece out.

- Stack final products in a pile as required that makes the sequent stages more convenient. e.g. spreading filling or packing and freezing pastries for sale.

Pre-pressing and compressing improve efficiency.

To compress meat patty into flat circle is related to the pressure of pressing device and the duration of pressing action. However, if we would like to boost productivity, single row of pressing plates is not enough. Therefore, ANKO installed one more row to implement two pressing processes- pre-pressing and compressing. Also, the ready-to-press and pressed products are conveyed at a certain rate to smoothly work with the pressing processes. As if two people press at the same time, clients can achieve maximum capacity and efficiency with less effort.

Tension adjustor to keep smoothing film.

The film conveying device equips two sets of film puller. Film puller A clips and conveys film to film puller B. Then, film puller A loosens and returns to its original position while film puller B clips. The action repeats to pull film. However, the film roll will become lighter, the film will be pulled too much and wrinkled as covering on products if the machine acts as usual. ANKO's engineer designed a device to increase the film roll's resistance to adjust the film tension. The measure prevents wrapping film wrinkling up.

- Solution Proposal

Experience Authentic Taste through ANKO's Kubba Mosul Pastry Machine

ANKO did

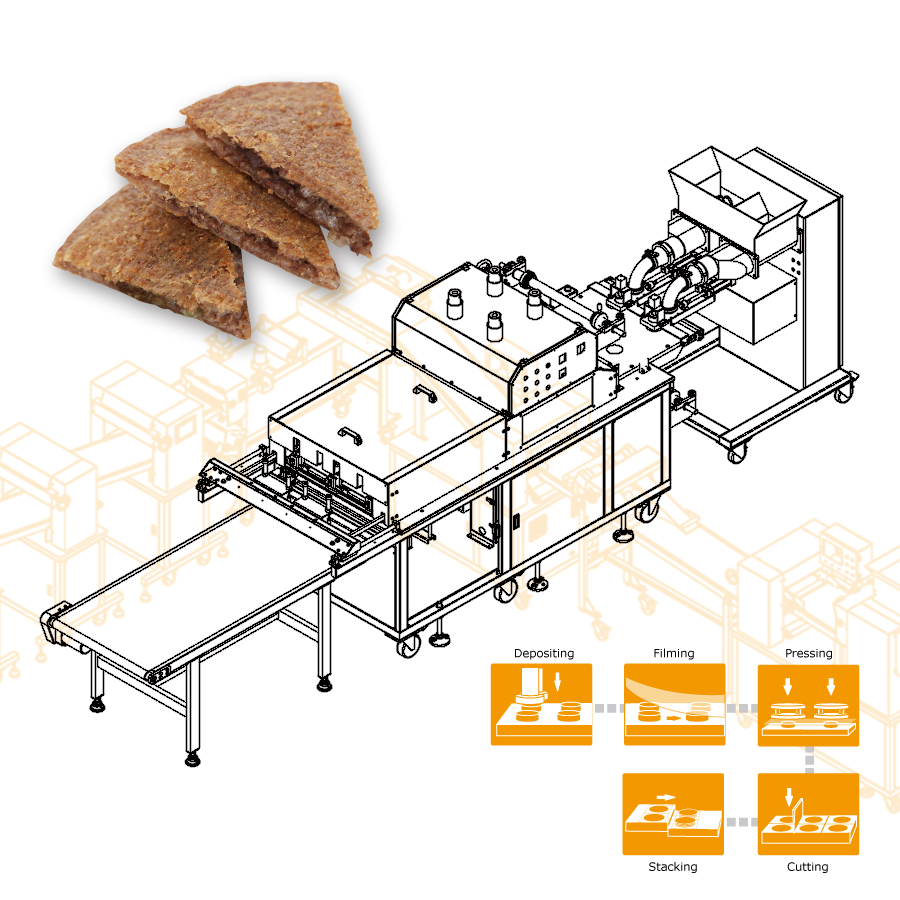

Transitioning from traditional handmade methods to automation is simplified with ANKO's Kubba Mosul Pastry Production Line. Capable of crafting 100 to 200 grams per piece and producing 2,400 pieces per hour, this machinery significantly reduces labor and operational costs.

ANKO can help you more

Following the production of Kubba Mosul Pastries, our Packaging and X-Ray Inspection Machines ensure quality control, enabling expanded distribution opportunities. ANKO not only maintains the quality of Kubba Mosul but also offers recipe optimization, transforming culinary creations into lucrative business ventures. For further details on our services and benefits, submit an inquiry below or click Learn More.

- Machines

-

Kubba Mosul Pastry production line

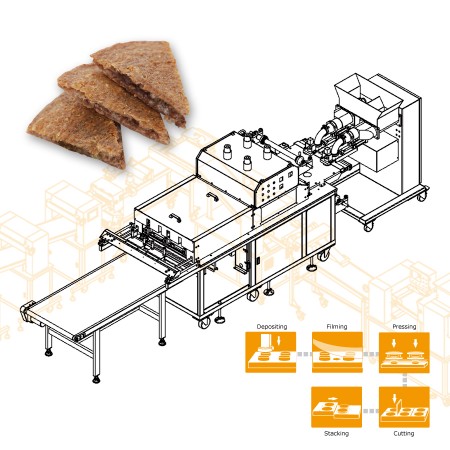

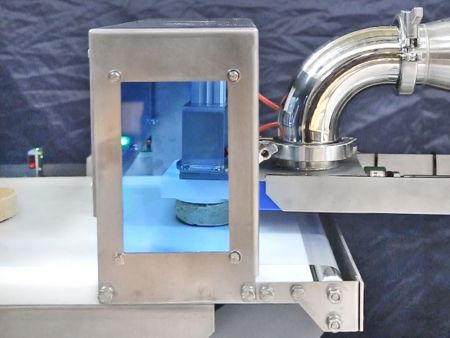

Kubba Mosul Pastry production line is combined with three sections--depositing, filming, and pressing. The depositing unit feature non-stick molds to maintain product quality and regularly deposit viscous patties. Through Automatic Filming and Pressing Machine, the meat patties are covered with top and bottom plastic film, then pressed into flat circle and cut up into pieces. The hourly capacity is 2,400 pastries. Finally, spread filling between pastries and press the edges of them manually.

- Country

Jordan

Jordan Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Jordan with advanced automated food production technology for making Spring Rolls, Kubba Mosul Pastries and Kibbehs. We also offer integrated solutions for popular foods such as Maamouls, Arabic Breads, Samosas, Sambouseks, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Kubba Mosul is commonly seen within frozen food products in Arab countries or Arabic stores in western countries. Compared with kubba, they are almost the same except for their shapes. Generally, both are made with fine bulgur, Middle-Eastern spices, minced beef or lamb, and then the mixture for making meat pastry is portioned out and rolled into flat circle. Spread chopped onion, minced meat filling on the center of a slice of meat pastry and cover with the other slice, then tightly press the edges to finish it like a UFO. Frozen Kubba Mosul products are effortless to find in every supermarket. People only have to put prepared filling between the ready-made Kubba Mosul Pastries, after 10-minute boiling or frying, all families can enjoy the delicious Kubba Mosul much easier.

- Handmade Recipe

-

Food Ingredient

Ground Lean Beef/Fine Bulgur/Salt/Water

How to make

(1) Soak fine bulgur in water until soft. (2) Drain fine bulgur. (3) Mix fine bulgur, ground lean beef, and salt in a bowl or a mixer. (4) Portion out the mixture. (5) Roll out each small meat ball into flat patty.

- Downloads

English

English