Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

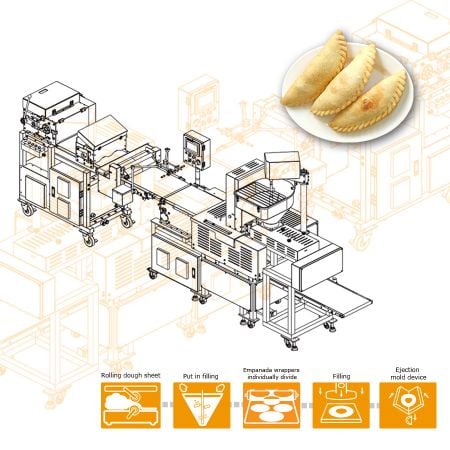

ANKO developed the high-capacity EMP-3000 Empanada Making Machine based on a client’s requirements in the United States. Our team conducted an in-depth analysis of operations at the client’s facility to understand the challenges of their Empanada production. This client needed a machine that could “quickly adapt to market demands while maintaining a high-quality product output.” After multiple test runs and refinement, the ANKO EMP-3000 Empanada Making Machine was launched. This model has a capacity of producing 3,000 Empanadas per hour to help clients’ productivity while saving on labor costs. The easy-to-remove filling system enables continuous production and improves quality control, providing a competitive advantage in food manufacturing.

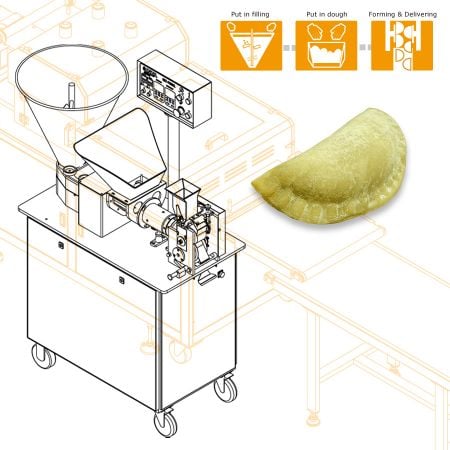

ANKO has found there is an increasing demand for Empanadas in the World marketplace. ANKO’s research has determined that this phenomenon not only exists in Spain and Latin American countries, but also in the USA, Canada, Australia, and the Philippines. And as a result, there is a great demand for automated Empanada machines. ANKO has been approached by many companies and different clients seeking a machine that can process high fat content dough such as puff pastry in order to make Empanadas. Currently, ANKO’s HLT-700 Multipurpose Filling and Forming Machine can produce Spanish style Empanadas with the capacity of over a thousand pieces of products per hour using a variety of forming molds. ANKO’s new EMP-900 Empanada Making Machine is our latest design for making Empanadas with high fat content pastry dough. ANKO’s team has devoted much time researching and developing our Semi-automated Clamping Mold Device, and it was tested using ANKO’s client’s recipe from the USA. This machine has successfully produced Empanadas that can be either baked or deep-fried and fulfilled ANKO’s client product specifications.

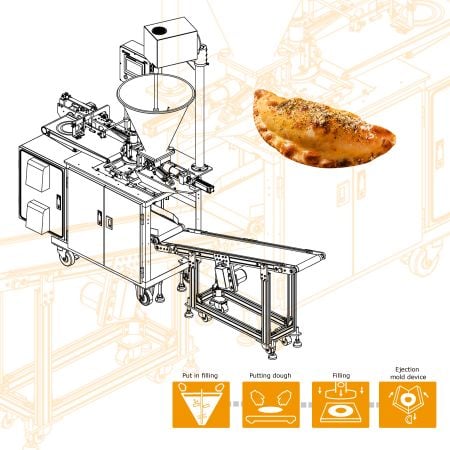

The client is an owner of a hotel chain in Tunisia. Speaking of cooking, their insistence on food has gained favor with visitors and got great comments on some travel websites. The calzone, both its recipe and ingredients, is handmade by their chef. As spending holidays in the hotel, tourists can buy a portable calzone at a concession stand and enjoy it as leisurely walking around. Due to the widespread reputation of the dish, they decided to buy a machine to meet the growing demand or the future launch of new menu in their restaurants. Then, the gourmet calzones could be produced in their central kitchen and distributed to each restaurant, which not only maintains product quality, but also cuts the labor cost.