ANKO's Har Gow (Shrimp Dumpling) Machine Supports a French Client's Business Expansion

This client is a pioneer in introducing Chinese Dim Sum for European markets; they started producing and selling premade frozen Dim Sum products to many different wholesale and retail stores in Europe and accomplished great brand recognition. However, considering the high labor costs in most European countries, this client approached ANKO for an automated production assessment. In order for their business to improve and expand they decided to purchase ANKO’s HSM-600 Siumai Machine; soon after this purchase the client returned to ANKO and purchased ANKO’s HLT-700XL Multipurpose Filling and Forming Machine for producing Har Gow (Shrimp dumplings). The purchase of both ANKO machines helped them accomplish their production requirements and meet market demands.

Har Gow (Shrimp Dumpling)

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. How to improve an automated Har Gow production process?

ANKO’s HLT-700XL Multipurpose Filling and Forming Machine can produce Har Gow using specialty clamping molds. However, the client used their original recipe for the dough wraps and it had slightly higher viscosity for automated productions. This resulted in product output deformation and affected the product’s texture after cooking. Therefore, the client consulted with ANKO’s engineers for advice……(Please contact us to get more information)

After adopting ANKO’s new recipe recommendations, the client tested production again and the final products achieved the desired textures. ANKO’s engineers also helped this client become more familiar with the operations and the abilities of this machine resulting in better overall performances.

Client's first attempt producing Har Gow with their original recipe and, results were below their expectations

Solution 2. The secret to successful new products – ANKO's professional consultation services during Research and Development.

In this specific case, ANKO assisted the client with technical support and recipe consultation services, which successfully helped them develop new great tasting new products by……(Please contact us to get more information)

Finally, ANKO also convinced the client to purchase ANKO’s equipment and helped them grow and expand their business.

Produce Har Gow with ANKO HLT-700XL – The key to successful automated Har Gow production is in the recipe, processing, as well as the parameter settings. This allows the production of Har Gow with the perfect wrap to filling ratio. ANKO has more than 48 years of experience in helping clients with automated food production solutions.

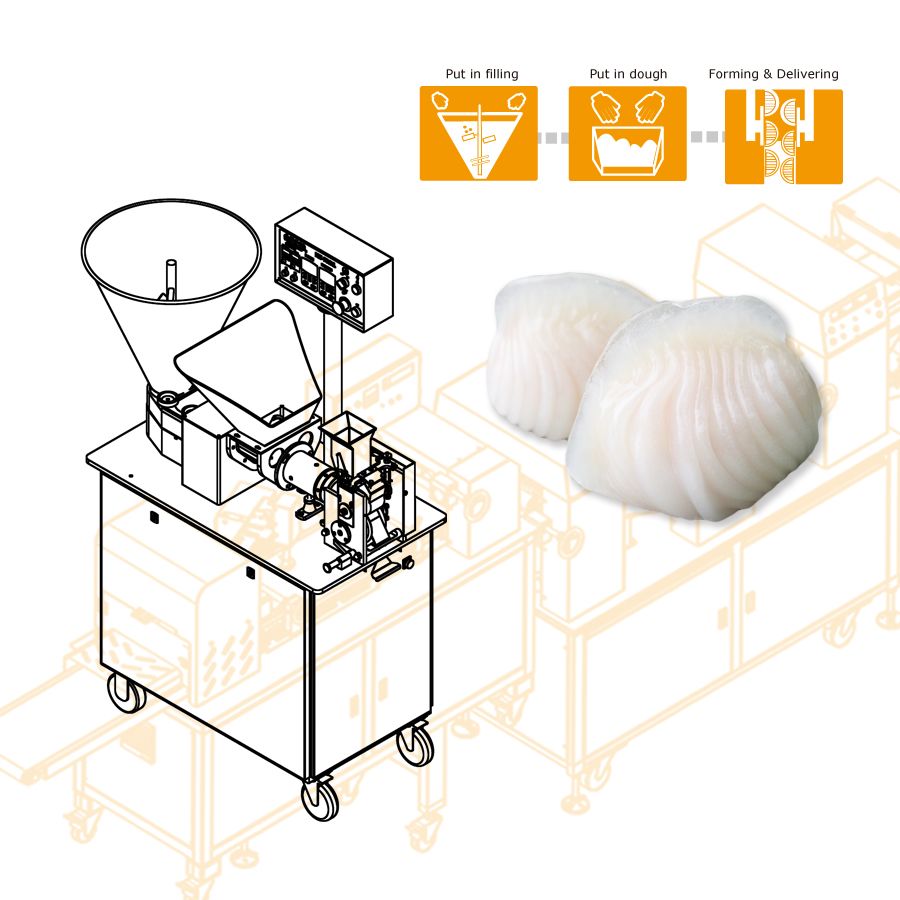

Food Equipment Introduction

- Place dough into hopper

- Place filling into hopper

- Automatically produce Har Gow with specialty clamping molds

ANKO’s HLT-700XL is designed to produce many different products

ANKO’s HLT-700XL Multipurpose Filling and Forming Machine was recommended to a client for its ability to produce Har Gow as well as many other products by simply changing the clamping molds. The molds come in half-moon, triangle, square, spherical and rectangular shapes. This allowed the client to expand their production line by making a wide range of different products, which is the main reason why they purchased the HLT-700XL.

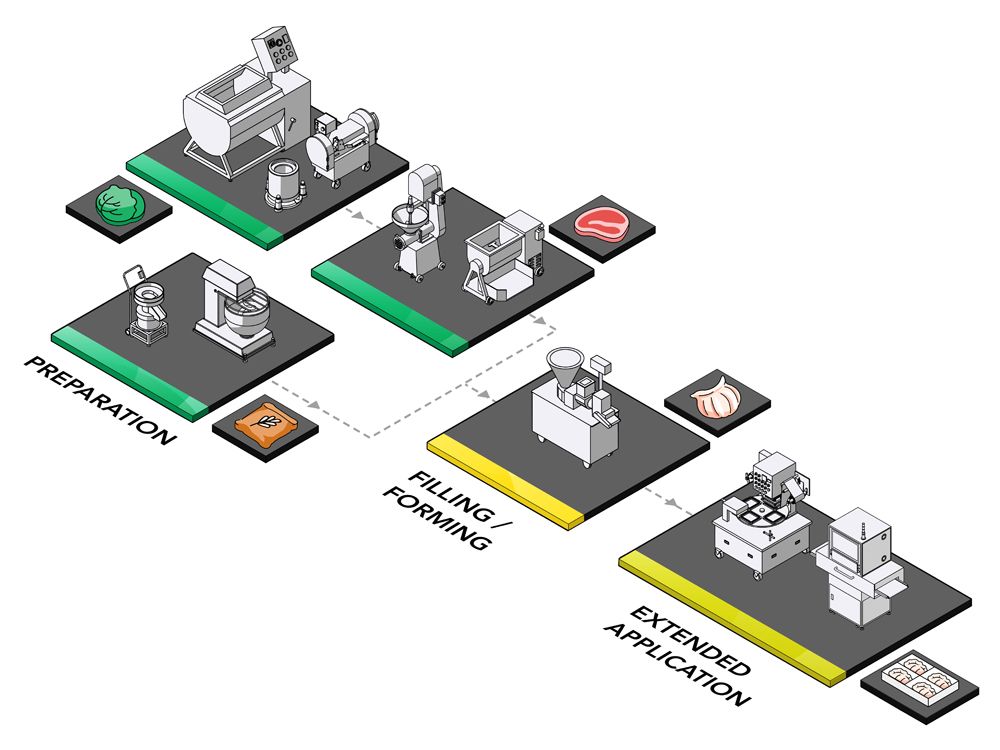

- Solution Proposal

Har Gow production solutions to meet your specific production requirements

ANKO did

ANKO offers professional food manufacturing equipment as well as supporting production solutions to help our clients build a complete production line. Our team of experts will assess your current facilities and suggest whether to add equipment such as food choppers, meat grinders, or dough mixers, as well as forming machine or packaging devices if necessary.

ANKO can help you more

ANKO also has a Food X-Ray Inspection Machine that can detect foreign objects during the production to increase the food safety and the quality of your products.

If you’re interested in more information, please click Learn More or feel free to fill out the form below, and we will get back to you as soon as possible.

- Machines

-

HLT-700XL

A client purchased ANKO’s HLT-700XL and successfully produced great tasting Har Gow that were well received by the marketplace. Soon after this success, the client came back to ANKO and procured Ravioli and Samosa molds to create new products for their business. ANKO’s HLT-700XL has a maximum capacity of 10,000pcs/hr., which was the solution for this client’s production needs and business expansion. Besides, It has Built-in IoT System that intelligently integrates food production lines. Through mobile devices, production status can be monitored remotely, and the IoT also sends machine maintenance schedule reminders, significantly reducing the risk of downtime.

- Video

- Country

France

France Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in France with advanced automated food production technology for making Har Gow, Kibbeh and Soup Dumplings. We also offer integrated solutions for popular foods such as Empanadas, Tortilla, Dumplings, Mochi, Samosas, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

In Hong Kong–style teahouses, Dim Sum is the most popular category on the menu. Steamed, fried, or boiled, these bite-sized dishes have evolved into a variety of signature classics. Among them, “Har Gow” (shrimp dumplings) are a must-order at every table, featuring translucent crystal-like wrappers and a pleasantly springy texture that diners love. In France, Dim Sum is especially popular in Paris, where many renowned restaurants such as Yoom, DimDimSum, and Le Lys d’Or offer modern or creative interpretations. Some businesses have also launched frozen Dim Sum products available on e-commerce platforms, allowing consumers to enjoy them at home and gradually integrating the tea house culture into the local dining scene. As France places great importance on food and wine pairings, Dim Sum restaurants in the country also incorporate alcoholic beverages, creating a new generation of dining experiences.

In France’s chain supermarkets and Asian grocery stores, such as Carrefour, Auchan, and Epiceries, frozen Har Gow can be easily found. To make this delicacy accessible to vegetarians, some producers also offer vegetarian versions, using tofu or vegetables as fillings that taste just as delicious when paired with sauces. With the growing popularity and diversification of Dim Sum in France, Har Gow has become not only a symbol of cultural exchange but also a reflection of significant market potential and business opportunities.- Handmade Recipe

-

Food Ingredient

For Wrap-Wheat starch/Potato starch/Hot water, For Filling-Shrimps/Cooked bamboo/Pork belly/Chicken/Water chestnuts/Seasoning

How to make

(1) Chop shrimp, bamboo, pork belly, chicken and water chestnuts (2) Mix all the above ingredients together and season for later use (3) Mix wheat starch with potato starch than add hot water to form the dough (4) Knead the dough till it is smooth, add more potato starch when kneading (5) Shape the dough into a long roll and divide it into equally sized pieces (6) Carefully press each dough piece into round wraps, leaving one half slightly thicker which will be the bottom of the dumpling (7) Fold in a spoon full of filling in the middle of the wrap and seal it with pleats (8) Boil water and have a steamer ready (9) When water is boiling, place Har Gow (shrimp dumplings) into the steamer and steam for 5 min until they are cooked

- Downloads

English

English