Triple the Revenue by Switching to Automated Production Equipment! ANKO’s Fully Automated Siomay Production Solution for a Client in Taiwan

To boost production capacity, the client transitioned from manual to automatic manufacturing and contacted ANKO for a production solution. Initially, we recommended a Double-line Automatic Siomay Machine. Within two years, their number of restaurants had tripled. They then approached ANKO again to purchase another Siomay Machine to meet the demand from all their restaurants.

Siomay

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. ANKO provides recipe optimization to ensure optimal Siomay texture.

The client served Siomay at their “all-you-can-eat” buffet restaurant in Taiwan. They realized that most restaurants make Siomay to the order, but at buffet restaurants, Siomays are steamed and kept warm during mealtime, and the Siomay wrappers tend to become soggy over time. Therefore, ANKO developed new recipes for this client to make Siomay that can be steamed and kept warm while the wrapper texture remains intact. We can also develop customized Siomay made with various ingredients and flavors, creating recipes perfect for automated production. ANKO’s professional consultants and engineers can help create delicious Siomay products, providing clients with a significant competitive advantage.

ANKO creates the best Siomay recipes with the perfect wrapper thickness and texture to remain firm during extended steaming and warming time

Solution 2. Solve the issues of production capacity and human resources with the evaluation of ROI.

ANKO provides many food making machines. We will consider customers' current and future situations, taking customers' budget, required production capacity, human resources, expected profit, etc., before give them advice. For example, this client was considering to have a semi-automatic siomay machine. In the siomay production process, 2 to 3 people were required, responsible for mixing filling, making dough, placing trays, collecting siomay, and collecting trays. The production capacity was 800 to 1,000 siomay an hour.

We recommended that they purchase an Automatic Siomay Machine, as it has the capacity to produce six times as much siomay per hour with the same number of workers as a semi-automatic one. They would recover their investment in half a year to a year, and there was no need to create siomay daily. They then took into account their workforce, production capacity, and future goals. Despite their business continuing to grow, they wouldn't need to purchase another machine very soon. In the end, we worked together to ensure their food business was successful.

Food Equipment Introduction

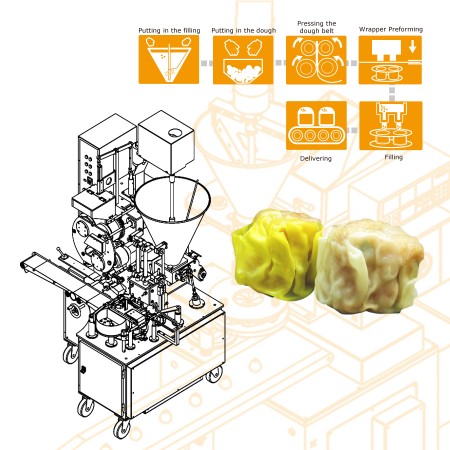

- Siomay dough shreds are pressed into a dough belt.

- The dough belt is conveyed and pulled in position.

- Two filling pipes fill stuffing on the center of siomay wrappers while the dough belt is cut into two wrappers and the wrappers are pushed in molds.

- Shaping grippers grip siomay to make pleats.

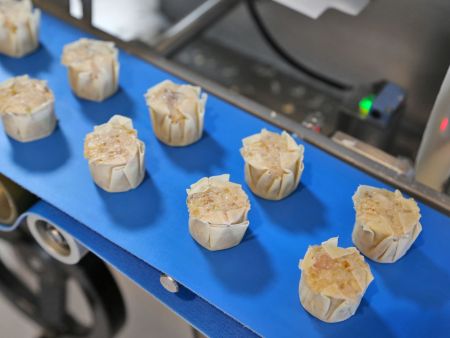

- Formed siomay are pushed onto a conveyor by pushers.

ANKO’s Siomay Machines are designed to meet various production requirements.

All food businesses and manufacturers have different production capacity requirements. Small restaurants may need to make 2,000 Siomay per day, while large factories could require a capacity of 100,000 or more pieces daily. ANKO’s Automatic Siomay Machines are designed with Single-line, Double-line, and Triple-line models to produce Siomay to fulfill your requirements. Our machine only requires minimal labor and oversight to reduce your production costs, producing quality Siomay with great quality and consistency, solving labor shortage problems while increasing production capacity.

- Solution Proposal

Industry-Leading Integrated Siomay Production Solution to Achieve Greater Success in Production

ANKO did

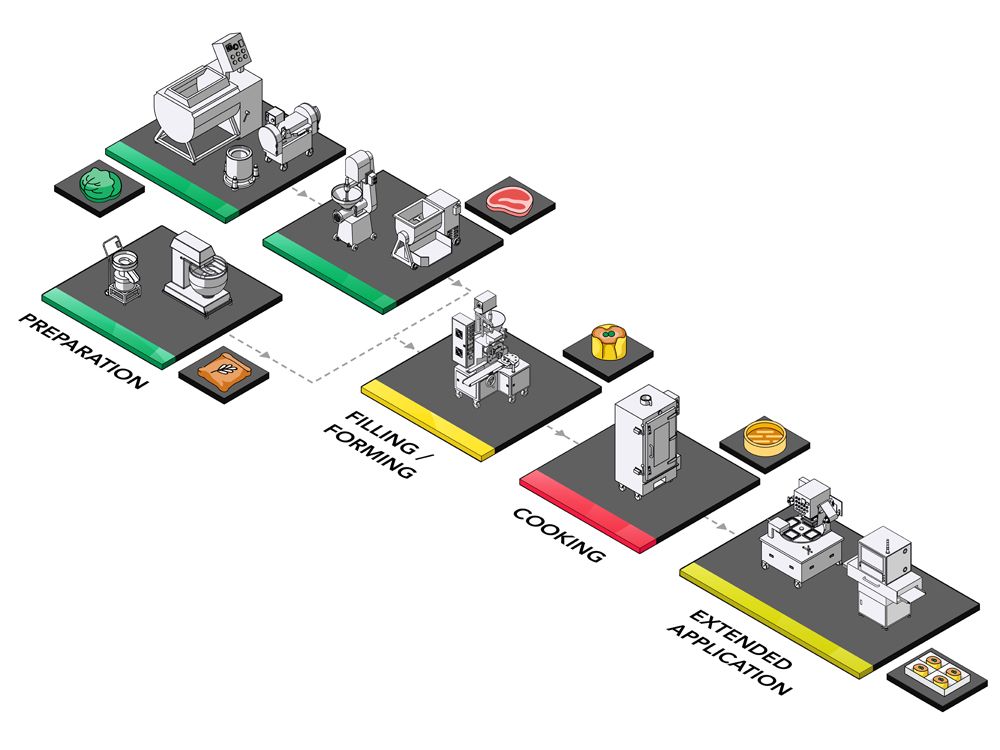

According to the client's current Siomay production situation, we helped him increase production capacity to adopt HSM-600 Automatic Siomay Machine and solve the human resources issues through the evaluation of ROI. Besides, we also offer recipe consultation and optimization to keep the client's desired taste.

ANKO can help you more

The Siomay Production Solution not only includes a filling and forming machine, but also mixer, vegetable cutter, meat grinder, steamer, packaging machine and food X-Ray inspection machine to set up a highly efficient Siomay Production Line.

If you need further information, please click Learn More or fill out the inquiry form below.

- Machines

-

HSM-600

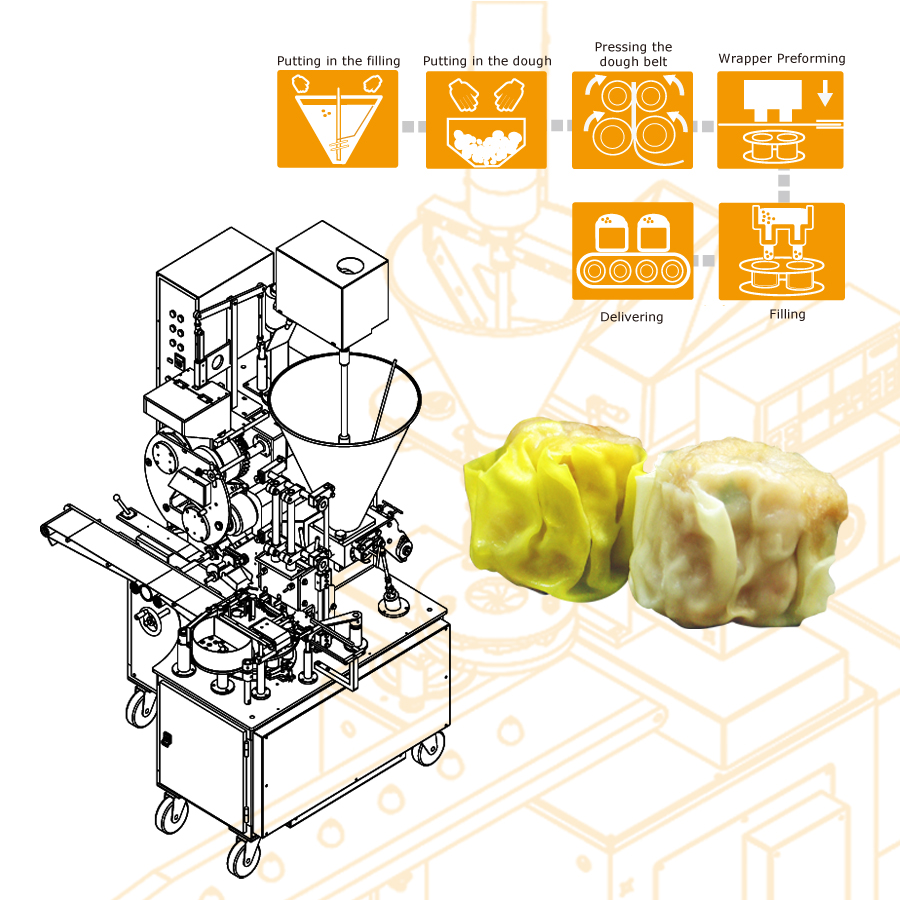

Simply putting prepared dough and filling, HSM-600 Automatic Shumai Machine can automatically make 6,000 siomay per hour and minimize hand contact with food. The heights of siomay filling and wrapper are customizable. If you want to make your siomay more colorful and tastier, a system for putting peas or carrot cubes on top of siomay is optional. Moreover, HSM-600 can also be customized to produce extra large Siomay (Dim Sim) that are 80g per piece. The Internet of Things (IoT) system has been introduced to the HSM-600 machine to provide access to remote monitoring via mobile devices. This reduces labor on the line, and provides real-time production information to monitor your production output. The System is also programmed to identify necessary part replacements, and automatically provides maintenance reminders that increases efficiency, and lowers overall production and maintenance costs.

- Video

How does the automatic double-line siomay machine work? In this video, you will see how the machine rolls out wrappers, fills stuffing, and shapes siomay. At the end of the production process, siomay are pushed onto a conveyor that helps workers collect final products. With a double line design, two siomay can be made at a time to increase productivity.

- Country

Taiwan

Taiwan Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Taiwan with advanced automated food production technology for making Dumplings, Potstickers, Noodles, Shumai, Scallion Pies, Steamed Custard Buns, Tapioca Pearls, and Sweet Potato Balls. We also offer integrated solutions for popular foods such as Baozi, Wonton, Spring Rolls, Pineapple Cakes, Xiao Long Bao, Tang Yuan, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Siomay (Shumai) is a traditional Chinese Dim Sum dish that can be made in many different styles. For example, bite-sized Cantonese Siomay can be made with pork, fish paste, and shrimp then steamed in a small basket; Shanghai-style Siomay is filled with glutinous rice, pork, and mushrooms. Filipino “Siomai” is commonly made with ground pork, minced carrots, garlic, and green peas, wrapped in wonton wrappers, and they can be steamed or deep-fried.

The Cantonese-style Siomay is the most popular, and it is commonly served in traditional tea houses in Hong Kong, Macao, and numerous Chinese communities. The rise of global Dim Sum restaurants as a trendy dining option has further cemented Siomay's place on the menus. Its increasing demand inspired food manufacturers to offer various frozen Siomay products for consumers to prepare using the microwave, steamer easily, pan-fry, or deep-fry to quickly and conveniently serve Siomay at home.

Increasing consumer demand for healthy eating has also created new opportunities in the Siomay business. Producers have introduced low-fat and reduced-sodium Siomay made with ground chicken breast and even gluten-free and lower-calorie Siomay made with bean curd/tofu skin instead of regular wrappers. Many meatless options include Truffle Siomay made with soy protein infused with truffle flavors, and Jade Green Siomay and Tofu Siomay for consumers preferring vegetarian and vegan options. There is a growing number of Siomay producers in Asia and markets Worldwide, showcasing the broad appeal and potential business opportunities of producing this popular product.- Handmade Recipe

-

Food Ingredient

For wrapper-All Purpose Flour/Warm Water/Salt, For filling-Ground Pork/Shrimp/Salt/Sugar/White Pepper/Wine/Sesame Oil/Mashed Ginger/Mashed Garlic

Making the Wrapper

(1) Add all purpose flour and salt in a large bowl and stir them together. (2) Add 65℃ water while stirring and keep stirring to mix flour and water. (3) Knead the dough by hand until there is no lump. (4) Cover with cling wrap and rest for 20 minutes. (5) Sprinkle flour on your work surface and knead the dough until smooth. (6) Put it in a bowl, cover with a wet cloth, and rest for one hour. (7) Roll the dough into a cylinder. (8) Cut it into small dough balls, around 5 grams. (9) Roll out a dough ball into a thin round wrapper.

Making the Filling

(1) Add ground pork and shrimp into a food processor and then mince and mix them until the mixture becomes viscous. (2) Add salt, sugar, white pepper, wine, sesame oil, mashed ginger, and mashed garlic into the food processor and mix them together. (3) Put the mixture in the fridge.

How to make

(1) Take out siomay filling from the fridge. (2) Make a circle with your thumb and index finger. (3) Place a siomay wrapper on the circle and spoon filling on the wrapper. (4) Wrap the filling and shape it with your thumb and index finger.

- Downloads

English

English