ANKO's Spring Roll Machine Resolves a British Company's Difficulties with Products Containing Highly Viscos Filling

The client runs restaurants, Indian food retail stores, and food factories at the largest Indian community in Birmingham, UK. Their major consumers are the Indians in the UK. Years ago, the client bought a food machine from ANKO. Without a machine trial before purchase, its user-friendly design, intuitive operation, and stable production and ANKO's services gave him a great impression. Therefore, he placed another order for spring roll production line this time because he thinks ANKO is reliable. (The SR-24 is no longer available. The new model is SR-27 machine.)

Paneer Spring Roll

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Sticky paneer makes the filling device unable to work smoothly.

The filling of the vegetarian spring roll contained homemade paneer, green chili pepper, and mixed vegetables (peas, carrots, and corn). When they made spring rolls by hand, they used freshly-cooked filling. Melted paneer did not cause any problem when making by hand but it did by machine. Melted paneer was sticky and stuck to the filling device.

The client asked to remain the taste and texture of his spring rolls, so we used several ways instead of adjusting his recipe to solve the problem. First of all, mix all ingredients……(Please contact us to get more information)

Solution 2. High moisture content in the filling affected machine operation.

When preparing the vegetarian filling, all ingredients and seasonings were mixed together at a time. The seasoned vegetarian filling releases water after a while and wets spring roll pastries. When making spring rolls with a machine, spring roll pastries were wet and stuck to the machine. In order to minimize water releasing from vegetables, we assisted the client on improvement of the preparing process for filling. As mentioned above, firstly……(Please contact us to get more information)

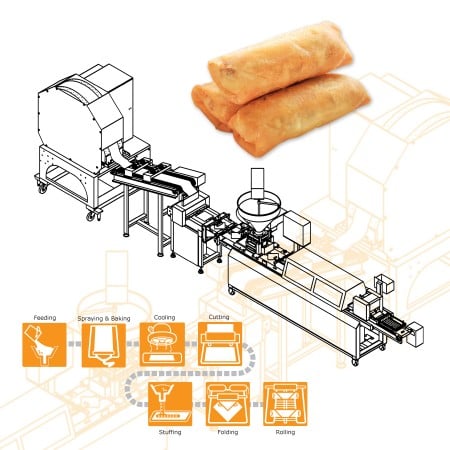

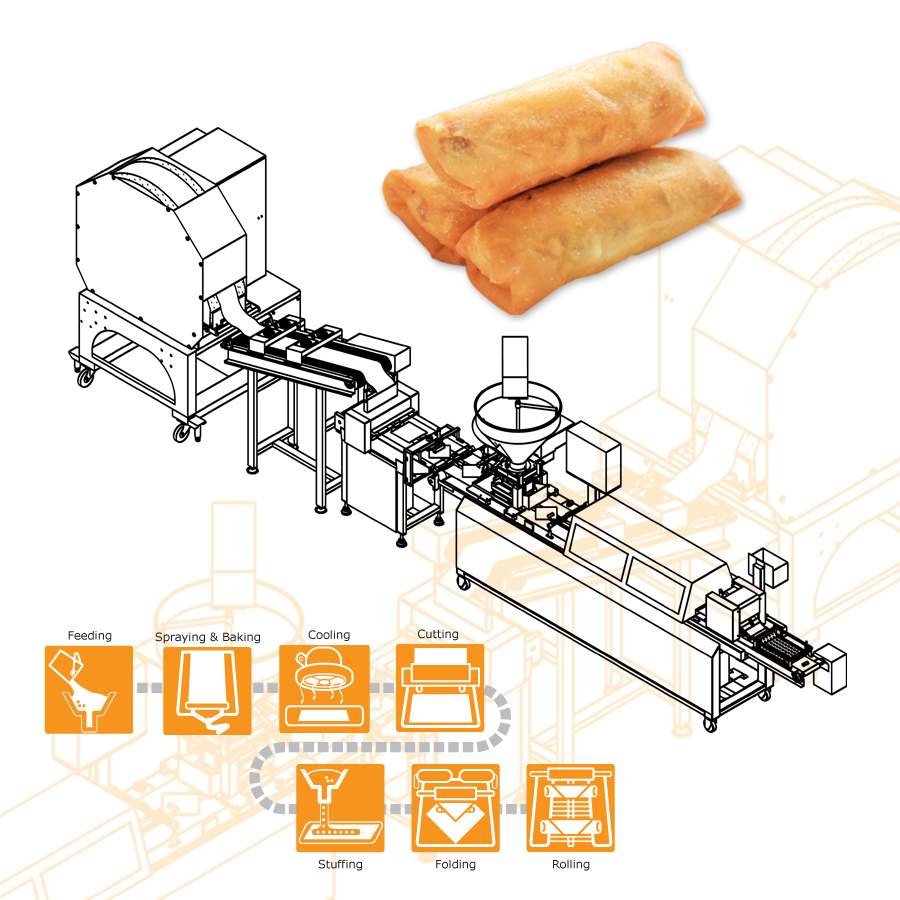

Food Equipment Introduction

- Batter baking

- Pastry cooling

- Pastry cutting

- Pastry rotating

- Filling depositing

- Folding

- Rolling

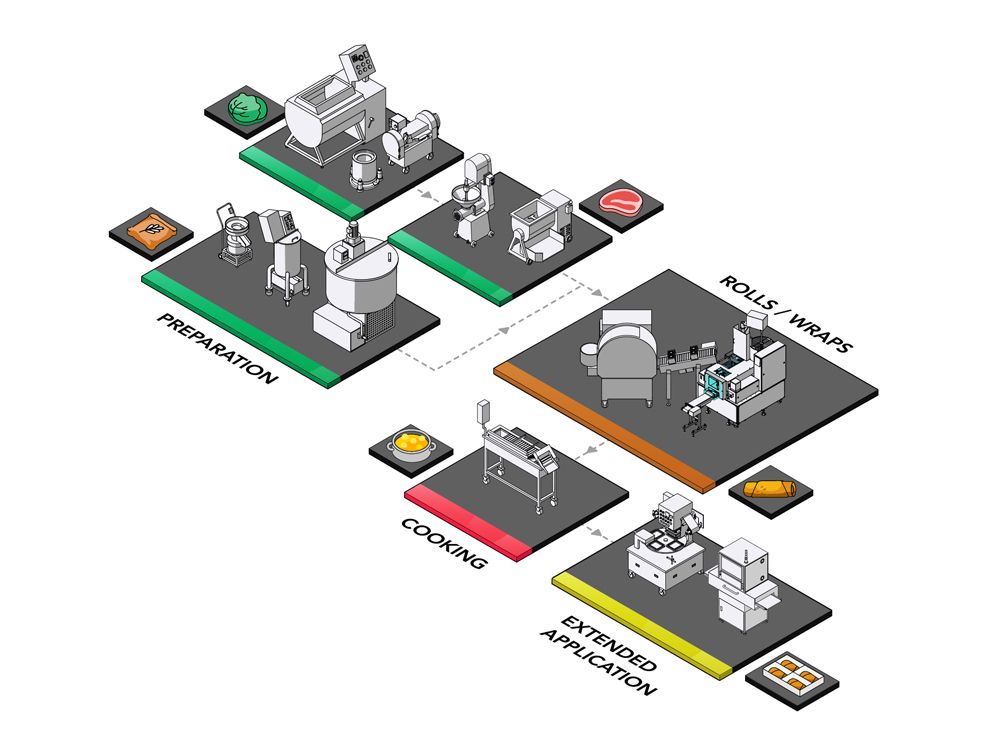

Automation solutions: Provide plans and solutions that suit your needs according to ingredients in your country.

During the transition from manual to automatic production, the most seen problem is that the original recipe is not suitable for automatic production. Take the case for an example, melted paneer did not make any trouble when wrapping spring rolls by hand but it stuck to the machine. ANKO values all our clients and understands the importance of passing on the original taste and texture of food. Therefore, we will satisfy our clients' requirements of automatic production through our experience in food and machine to optimize equipment or production process.

- Solution Proposal

High Quality Spring Roll Production Equipment

ANKO did

ANKO supplies customized Spring Roll Production Equipment, and our team of professionals can provide you with integrated production solution services to help you procure and set up an efficient automated Spring Roll production line. ANKO's Food Lab, in our Taiwan Headquarters, has a fully equipped kitchen and our food researchers can help test and modify your recipes to ensure efficient food production.

ANKO can help you more

ANKO's machines can produce perfect Spring Roll products based on your product specifications; and our professional consultants and engineers offer consultation services for the transitioning process from manual to automated food production.

If you are interested in ANKO machines or more information about our services, please click Learn More or complete the form below and we will get back to you as soon as possible.

- Machines

-

SR-24

The Spring Roll Production Line features fully automatic production from pastry baking, filling depositing, to spring roll folding, which help customers switch from manual to automatic production easier, save time, and increase production capacity. Users only need to pour in prepared batter and press the start button, the machine will bake pastry, cut into square pieces, deposit filling, fold and roll into spring rolls. The final products can be directly deep-fried or packed. In addition, the Spring Roll Production Line can work a wide variety of filing such as sticky cheese filling mentioned in the case, vegetable filling, meat filling as well as vegetable and meat filling. (The SR-24 is no longer available. The new model is SR-27 machine.)

- Video

- Country

United Kingdom

United Kingdom Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in United Kingdom with advanced automated food production technology for making Spring Rolls, Wonton, and Rasgulla. We also offer integrated solutions for popular foods such as Dumplings, Samosa, Kibbeh, Panzerotti, Paratha, Momo, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Spring roll originated from China, which is eaten for celebrating the coming of spring. With Chinese emigration, the traditional dish has been brought to other countries and evolved into regional dishes, for example, American egg roll is bigger than spring roll and Indian spring roll is seasoned with spices. Even so, they are all made with these 4 steps – spring roll pastry making, filling preparing, wrapping, and frying.

- Handmade Recipe

-

Food Ingredient

For pastry-All Purpose Flour/Water/Salt, For filling-Ginger/Garlic/Onion/Oil/Paneer/Cabbage/Carrot/Peas/Lemon Juice/Chili Powder

Making the Pastry

(1) Add all purpose flour, water, and salt into a large bowl, mix them well. (2) Rest the batter for one hour.

Making the Filling

(1) Chop ginger, garlic, onion, paneer, cabbage, and carrot. (2) Pan fry all ingredients until soft. (3) Season with lemon juice and chili powder.

How to make

(1) With a pan, cook the batter into thin spring roll pastries. (2) Make a spring roll by wrapping pastry around some filling. (3) Deep-fry all spring rolls.

- Downloads

English

English