Automatic shumai machine designed to solve supply shortages of shumai

The client is a co-packer, who has been contracted by many food companies to produce Chinese food and dim sum. He has been using ANKO's double-line shumai machine for years and gives ANKO credit for the high quality machine. Recently, due to the COVID-19 lockdown, the demand for frozen food and ready-to-eat food is growing while people are unable or less willing to eat in restaurants. Therefore, a chain restaurant, who is well known for its shumai, was seeking new opportunities. The company would like to sell ready-to-heat shumai in convenience stores and supermarkets. It then contracted our client to produce the delicious shumai. As a result, our client planned to purchase another shumai machine. He said, "if you have triple-line shumai machine, we'll definitely buy one. It will be perfect."

Shumai (Siomay)

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Low production capacity cannot meet the growing demand

"if you have a high-capacity shumai machine, we'll definitely buy one." ANKO bear the client's need in mind and set out to design a shumai machine with high production capacity.

The triple-line shumai machine retains the design principles and structures of the double-line model. The appearances, sizes, and operation of the two models are almost the same. If you would like to replace your double-line model with the new one, there'll be only minor changes to the current setup and you can save time giving another training.

Compared to the double-line model, the triple-line shumai machine has an increase of 50% in capacity, from 6,000 to 9,000 shumai. In other words, if you supply shumai in a pack of 30, the new shumai machine can help you produce 2,400 packs per day. Moreover, this upgraded machine retains the same advantages as the double line model, both are suitable for a wide range of dough and filling and can make various flavors of shumai. Therefore, with a triple-line shumai machine, you could create new flavors and provide combo or seasonal shumai packs, while the supply of general flavors is sufficient.

The triple-line shumai machine is designed to not only boost production capacity, but also support clients' business growth. For example, co-packers could build their own brands; ready meals companies could work with restaurant chains providing ready-to-eat shumai to enable consumers to savor famous dishes.

Solution 2. Improve efficiency of manual collection

In addition to increasing the production capacity, ANKO's R&D engineers hoped that the users could use and work with the machine more easily and enhance efficiency. They redesigned shifting rods from fixed to movable to adjust spacing between shumai according to the cells of your containers, or to a minimum, which solved the problem that workers used to collect several shumai together in order to pick as many as shumai at a time. In production management, any step counts even though it is a slight movement. Therefore, we innovated the adjustable spacing function to replace the movement of collecting or arranging and made the manual process to be only "picking and placing".

Solution 3. Increase the level of automation

ANKO is the business partner that grows with you. Increasing production capacity is the first step, and the step two is to provide corresponding front- and rear-end equipment. When designing the triple-line shumai machine, ANKO's engineers took client scenarios into consideration. In addition to human-machine cooperation, clients might need to increase the automation levels, so our engineers developed an aligning machine to work with the HSM-900 Shumai Machine.

The ALT-600 Aligning Machine can arrange shumai on trays perfectly and is equipped with tray descending unit to pre-set 15 trays and deliver empty trays, facilitating staffing and production arrangements.

With the spacing adjustable function of the HSM Shumai Machine and the precise aligning conveyor of the Aligning Machine, shumai can be arranged very close to each other, to ensure the most utilization of the trays.

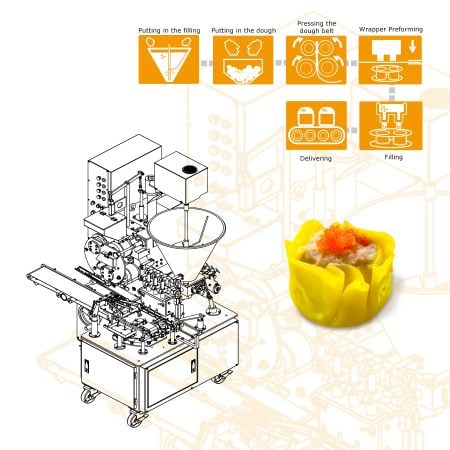

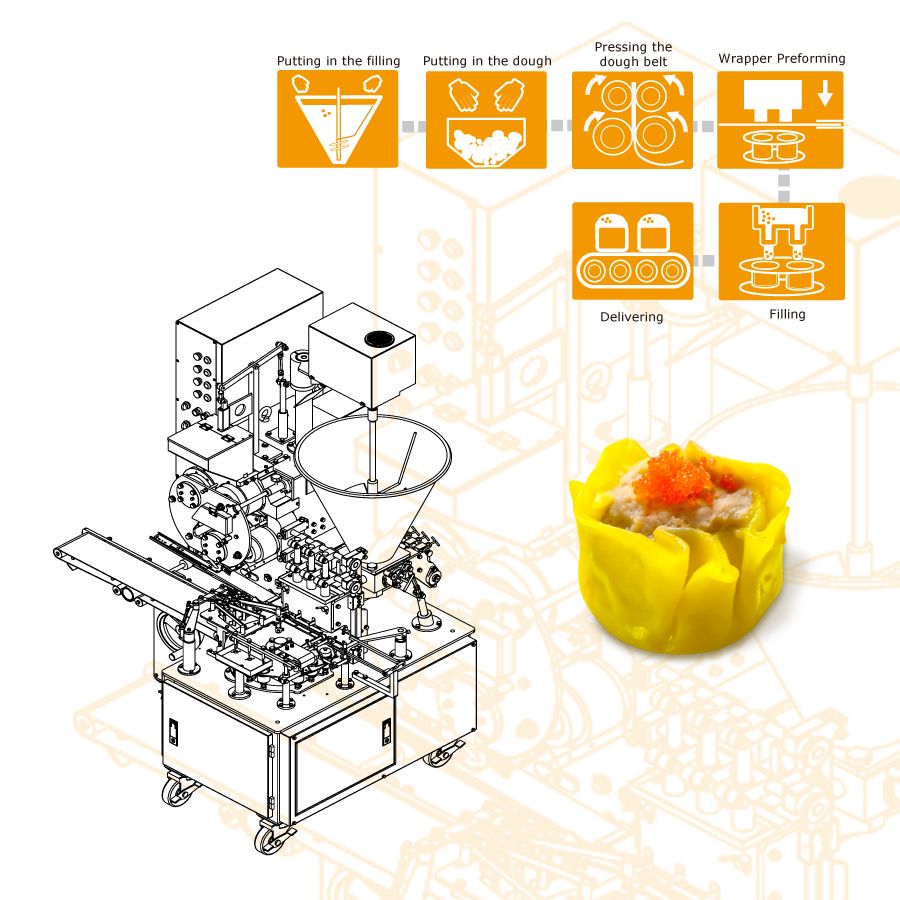

The video will show you how the shumai machine operates from dough belt making, cutting, positioning, filling, forming, to decorating. Also, as mentioned above, the upgrade shumai machine is designed with new mechanism, which runs smoothly and quietly. In this video, we particularly record the sound for you to experience. Please click to play now!

Food Equipment Introduction

- Dough belt pressing

- Gripping

- Cutting

- Wrapper preforming

- Filling

- Forming

- Delivering

What makes great design?

Designing by numbers. Carrying out in-depth research before developing a machine is necessary, also before this upgrade from double-line to triple-line model. With after-sales service records, our engineers optimized the parts that wore out fast or broke unexpectedly. They utilized the data to obtain precise values and replaced the parts with more appropriate ones to decrease frequency of repairs. For example, when designing the triple line shumai machine, our engineers calculated the applied force of each unit and installed springs with corresponding tensile strength. In addition, this sales database assisted us with the understanding of the market need for shumai size, so we had listed a range of regular modules for customers to choose from. For ANKO's engineers, all small details matter.

- Solution Proposal

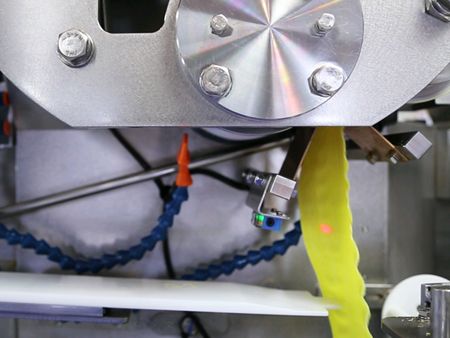

ANKO's Shumai Production Solution Satisfies All Your Needs

ANKO did

Are you considering producing Shumai from manual to automation? With more than 48 years experience in the food machinery industry, ANKO can offer integrated production solution services to help you set up an efficient automated Shumai production line. Our professional team can configure different models to find the most appropriate Shumai machine and install an affordable production line based on your needs and required production capacity.

ANKO can help you more

A custom-made one-stop Shumai Solution includes a dough mixer, vegetable cutter, meat grinder, filling and forming machine, packing and food X-ray inspection machines. Besides, ANKO can also offer workflow, factory layout, shumai recipe optimization or adjustment to achieve greater success in producing Shumai automatically.

If you are interested in more information, please click Learn More or complete the form below.

- Machines

-

HSM-900

The upgrade shumai machine features high production capacity, aiming to solve a limited supply of frozen shumai, suitable for food factories, co-packers, central kitchens, and restaurant chains. For food factories, the triple-line shumai machine might assist you with the development of product lines. For co-packers, you might not to share orders with other co-packers from an outsourcer. And for central kitchens and restaurant chains, with a shumai maker, you could save the cost of manual production, training, or buying ready-made shumai wrappers, and take the taste and texture of shumai as well as food hygiene and safety into your own hands.

- Country

Taiwan

Taiwan Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Taiwan with advanced automated food production technology for making Dumplings, Potstickers, Noodles, Shumai, Scallion Pies, Steamed Custard Buns, Tapioca Pearls, and Sweet Potato Balls. We also offer integrated solutions for popular foods such as Baozi, Wonton, Spring Rolls, Pineapple Cakes, Xiao Long Bao, Tang Yuan, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

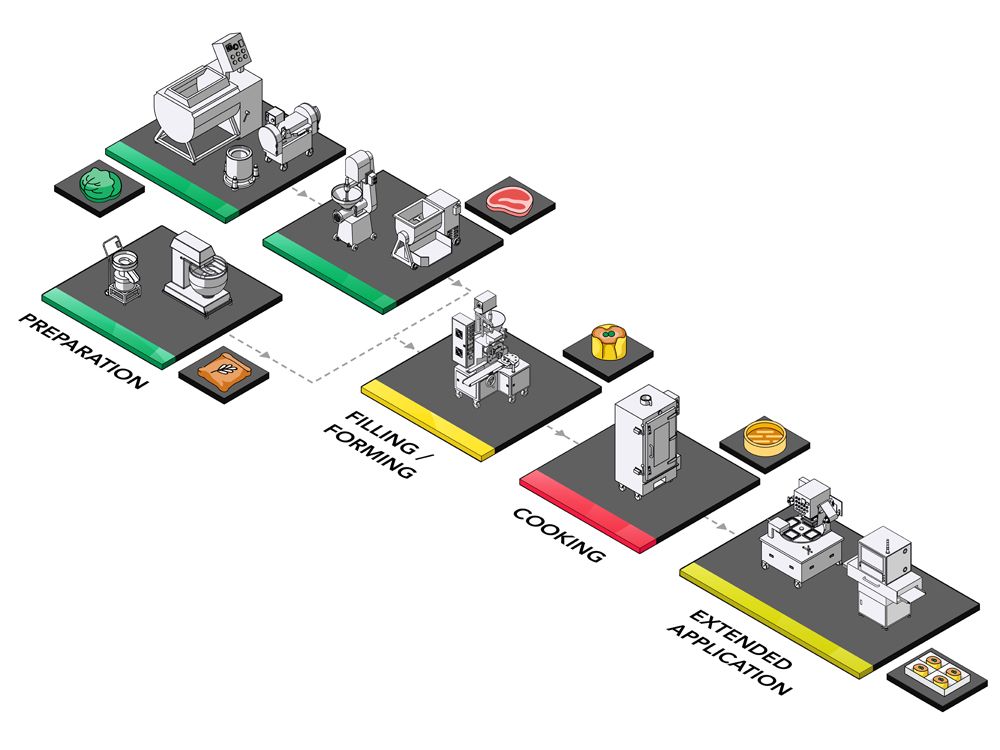

Shumai is a type of Chinese food, originating from Hohhot. It is usually made with pork or fish paste and wrapped around a very thin wrapper. However, when you travelling to different countries, you may be surprised that the shape and serving way are so different from the traditional shumai. For instance, in Hong Kong, shumai is formed into a cylinder, serving in a bamboo steamer, which always dominates the list of the popular dim sum. In the Philippines, siomai is sometimes eaten with rice.

- Handmade Recipe

-

Food Ingredient

For wrapper-All Purpose Flour/Salt/Water, For filling-Shiitake/Shrimp/Ground Pork/Carrot/Scallions/Ginger/Egg/Sesame Oil/Shaoxing Wine/Salt/Ground White Pepper

How to make

(1) The shumai wrapper is made with flour, salt, and water. The mixture will be formed into dough and then rolled out into a thin sheet. Finally, use a square or circle mold to cut the sheet into pieces of shumai wrappers. (2) To make the shumai filling, combine chopped shiitake, shrimp, ground pork, carrot, scallions, ginger, and an egg together, and then season with cooking wine, salt, and ground white pepper. Stir them well until the mixture becomes sticky. (3) Scoop filling in the center of the shumai wrapper. Wrap the filling and leave the top open. Form and shape shumai into a cylinder. Finally, top the shumai with finely diced carrots if you like.

- Downloads

English

English