Fried Apple Pie Making Machine – Machinery Design for Panamanian Company

The client has run Korean restaurants in Panama, where are viewed by local people as a good place to satisfy your taste buds and stomach. At that time, the owner wanted to serve more dishes in his restaurants and sell on other channels. To achieve the goal, his central kitchen had to supply various kinds of food and increase production capacity. Moreover, with the government's protectionist policies, he thought buying a machine would be good investment. Then, someone introduced ANKO and our HLT Series Multipurpose Filling and Forming Machine to the owner. During his visit to ANKO for machine trial testing, he realized that ANKO is reliable and able to offer customization and turnkey services. Finally, he chose ANKO as his business partner to grow with him.

Apple Pie

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Adjust recipe to make thin and crispy crunch

The client told us that he wanted his apple pie crispy. To get crispy texture, dough must contain a high amount of oil, but it broke easily. If we tried to solve the problem by making wrappers thicker, the apple pie crust would become firm. Therefore, our engineer used ……(Please contact us to get more information)

The crispy outer crust and the soft filling inside, similar to the McDonald's apple pie, perfectly matched up with the client's need and local taste.

How can a machine make apple pies with the wrappers that bubble after deep-frying?

The key to making bubbles form on wrappers is to have smooth dough. In this case, when the machine extruded dough out, pressure tore the dough, as a result, the rough surface was unable to form bubbles. To solve the problem, our engineers replaced……(Please contact us to get more information)

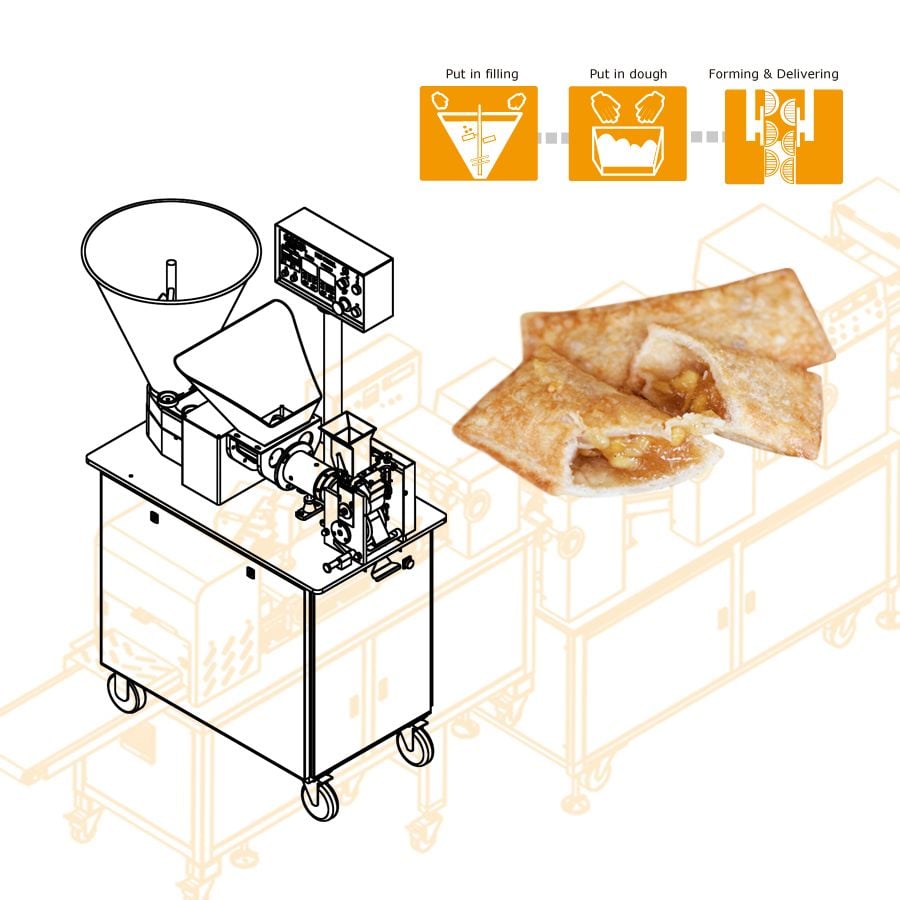

Food Equipment Introduction

- Mixer

- Dough kneading

- HLT-700XL

- Dough tube extruding

- Filling extruding into dough tube

- Forming with apple pie mold

The filling system can smoothly process filling with dices to retain food's texture

ANKO is dedicated to enhancing the quality and texture of machine-made food. To make foods with dices has been a challenge in building a food machine. The transfer from manual to automatic production should not compromise food's quality. Therefore, in order to retain the texture of apple dices, the filling screws and rotors of the HLT-700XL's filling system are designed to prevent a short burst caused by slipping and extrude dices smoother, which could make products in standard weight, keep food texture and provide consistent product quality.

- Solution Proposal

ANKO Food Lab: Your Best Partner in Crafting Innovative Food Products

At the request of our clients, ANKO adjusted their original recipe, turning Apple Pies into their desired products. Our experienced and dedicated professional team assists in transitioning your food production to automation, developing new products, and optimizing recipes for innovation. Whether you're launching a new food business or looking to enhance an existing one, ANKO offers comprehensive production planning and recipe ideas.

Automated All-in-One Apple Pie Production Solution

With a simple press of a button, ANKO's HLT-700 Machine can produce over 20,000 pieces of Apple Pies daily, catering to large-scale manufacturers. This versatile machine is not limited to apple fillings; it can also handle cheese, vegetable, meat, and shrimp fillings to create a variety of food products. To further enhance automation, we provide an all-encompassing production solution, from front-end to back-end equipment. Please click Learn More for more details to support your food business.

- Machines

-

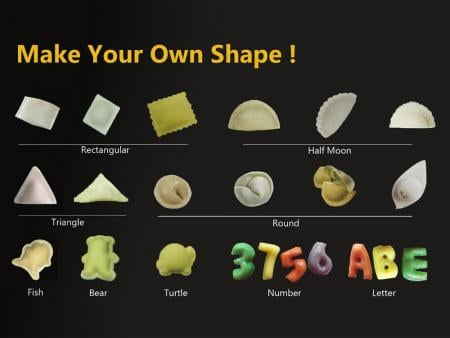

HLT-700XL Multiple Forming Molds

The major advantage of HLT-700XL is its flexibility to make over 30 kinds of dumplings, including Chinese dumpling, samosa, ravioli and apple pie. It is because that the forming mold is customizable and easy to change. In addition to square and round shape, unique shapes, such as bear, letter and figure, and special edges can be customized to help you make exclusive products.

The Built-in IoT System of HLT-700XL

ANKO launched the Internet of Things (IoT) System, using AI to integrate our automatic food production lines. All the data is collected onto ANKO's Dashboard. This Dashboard provides the machine's current operational status, including "Digital Production Management" services. It also displays real-time on-site production status, including data such as daily production volume, material waste, and issue reports to the remote monitors. More importantly, ANKO's IoT system automatically detects any parts that require maintenance and sends alerts to the ANKO Dashboard. This information can be easily accessed and will help to manage short-term and long-term maintenance goals better.

- Video

How does the apple pie machine work? The video shows different forming mold sets, making triangular ravioli, square ravioli, semicircular dumpling, stick gyoza, bear-shaped dumpling, ABC-shaped dumpling, 2-gram dumpling, and 200-gram calzone. Moreover, if you want to know how easy is it to change the forming mold set, please watch from 0:45.

- Country

Panama

Panama Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Panama with advanced automated food production technology for making Apple Pies, Empanadas and Shumai. We also offer integrated solutions for popular foods such as Arepa, Calzones, Pies, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Apple pie originated in Europe and developed into different shapes, sizes, and flavors such as caramel apple pie and French apple pie. Then, apple pie was brought to America and fused with American flavors. Since the Americas like fried food, the fast food restaurant chain changed the cooking method from baking to deep-frying, and made into a more convenient rectangular shape, making apple pie an iconic American snack.

- Handmade Recipe

-

Food Ingredient

Flour/Sugar/Salt/Cinnamon/Apple/Unsalted Butter/Corn Starch/Water

Making Wrapper

(1) Mix flour, cinnamon, sugar, salt, and butter together and then add water, then knead the mixture into dough. (2) Pat the dough down and wrap it with cling wrap. Put it into the refrigerator.

Making Filling

(1) Peel and dice apples. Add apple dices, butter, cinnamon, and water into a pan and heat it. (2) Add corn starch and stir-fry apple dices until soft. Turn off the stove and set aside.

Assembly

(1) Roll out the dough and cut it into squares. (2) Wrap the apple filling with the square wrappers and seal them completely. (3) Bake or deep-fry the apple pies until golden.

- Downloads

English

English