ANKO Created Extra Thick Spring Roll Wrappers for a German Company to Resolve Thinner Ready-made Wrappers

The client was using ready-made spring roll pastry sheets to produce organic fried spring rolls. Though he has to devote extra time on reprocessing each sheet before use, and reaching the thickness with the feeling of satiety. In order to increase overall efficiency, the initiation to implement his own pastry sheet production line rooted in his mind. He then found a Taiwanese food machine manufacturer called ANKO, which has years of experience in researching and developing food machinery. Not only can they modify the recipe according to the accessible local ingredients, but most importantly to solve the production problems that the client faced. Which is to produce extra thick spring roll wrapper that is 35 grams in weight and 0.9 mm in thickness.

Vegetarian Spring Roll Wrapper

ANKO Team Research Problem Solving or Solution Delivery

Make vegetarian spring roll wrapper thicker to satisfy customer's appetite.

The client was originally using ready-made spring roll pastry sheets to produce spring roll. With the average thickness of 0.6mm, he has to devote extra time on cutting and stacking each sheet. And the final product weighs one and a half wrapper combined.

Due to the time-consuming and laborious reprocessing work, he decided to implement a semi-automatic spring roll wrapper production line with ANKO Food Machine. In order to solve the production problem for our client, our engineer tried many options……(Please contact us to get more information)

As a result, the wrappers reached 0.9 mm and weighed 35 grams which is equal to two sheets of ready-made wrappers combined.

Food Equipment Introduction

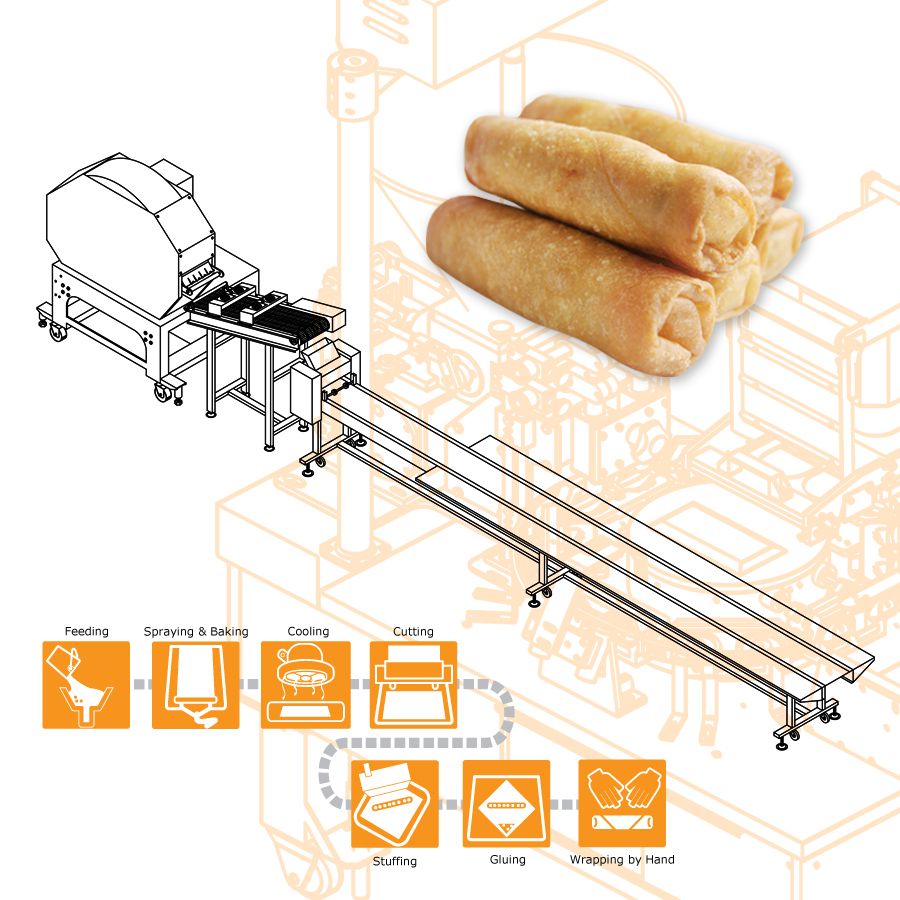

- Pour well-stirred batter into the batter tank.

- Set the temperature and rotating speed of the baking drum on the control panel.

- Machine starts spraying batter onto the baking drum.

- The freshly made dough belt will be cooled by cooling fans on the conveyor.

- The strip of dough belt will be cut into proper sized wrapper sheet automatically.

- Wrappers are further conveyed for subsequent manual processes.

What’s the purpose to locate a spray nozzle beneath the baking drum, which is close to the height of men’s knees?

The full utilization of baking drum

As the baking drum turns a three fourths of circle, batter will be cooked thoroughly into a strip of dough belt and scraped from the baking drum. As the remaining one fourth of the circle purposely remained empty for reheating and be ready for the next round. In other words, if the spray nozzle is installed from above the baking drum, it might need higher temperature to shorten the baking time needed before it rotates higher than the conveyor. Meanwhile, leaving too much unused surface and causing reduction of production efficiency.

Easy changing

The height of the spray nozzle is thoughtfully designed to be close to the height of men’s knees. Not just making the replacing process of spray nozzle easier, but also prevents danger from occurring for the operator to climb up and down for refilling batter. To assist our clients reaching maximum efficiency, leaving no unused parts, calculate the perfect baking temperature and time-needed for the recipe with repetitive testing. In other words, every detail is carefully calculated in your favor.

- Solution Proposal

ANKO's Spring Roll Wrapper Production Solution to Increase Your Production Efficiency

ANKO did

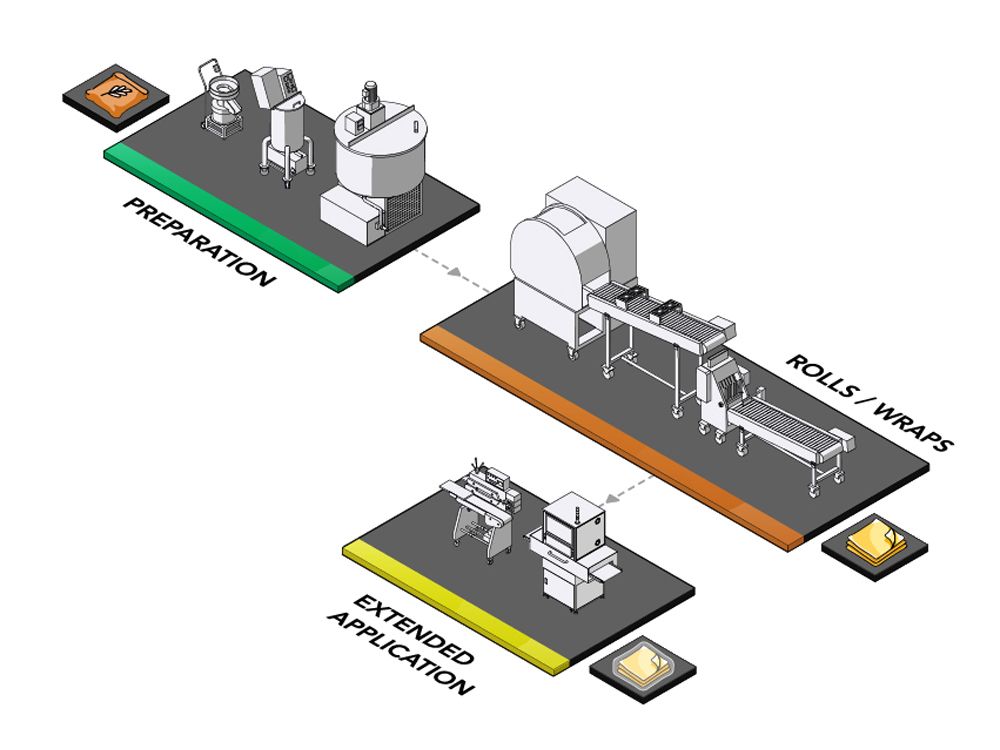

In this case, we recommended our SRPF Semi-Automatic Spring Roll Production Line for the client to make Spring Roll Wrapper by their own, in order to increase overall efficiency and save the extra working hours. After the wrappers are produced, they will roll the spring rolls by hand.

ANKO can help you more

If the client is contemplating transitioning into a fully automated production, ANKO can offer a total solution with different processing machines, from batter mixer, filling and rolling machine, to packing and food X-ray inspection machines, to setup a highly efficient Spring Roll production line.

If you are interested in more information, please click Learn More or complete the form below.

- Machines

-

SRPF

Due to the creative shape of the vegetarian fried spring roll, we recommended the SRPF Semi-Automatic Pastry Sheet Production Line instead. Which is specially designed to produce thin pastries such as spring roll wrapper, samosa wrapper, and etc., followed by an operating deck for manual process. The operating deck extends-out alongside the conveyor, which opens the possibility to customize on connectable machineries, and for individual needs. We also customized the conveyor into proper length based on human work rate and production speed, offering the most efficient production line.

- Video

The consistency of the batter for thick spring roll wrapper - The wrapper made by SRPF is two times thicker than the wrapper sold on the market. In order to save time on reprocessing each spring roll wrappers, the client bought the SRPF; spring roll wrapper production line. ANKO also helped him in adjusting the batter recipe and to test out the most suitable baking settings to produce 0.9 mm thick and 35 gram spring roll wrappers. The consistency of the batter is shown in the video.

Vegetarian fried spring roll wrapper production line - The batter to produce spring roll wrapper is spread onto the baking drum. Then, the strip of dough belt is cut into required size pastry sheets and delivered by the conveyor for the subsequent manual processes.

- Country

Germany

Germany Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Germany with advanced automated food production technology for making Spring Roll Wrappers, Pelmeni, Empanadas and Dumplings. We also offer integrated solutions for popular foods such as Samosas, Kibbeh, Momo, Pierogi, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

The Plant-Based Diet become more and more popular around the world and seem to be the future. Vegetarians of population in Germany are high among European countries. Thus, organic food is getting popular in Germany. The client (company’s owner) has background in nutrition, so he insists to offer consumers healthy and tasty foods all made with organic ingredients. Most of the spring rolls he offers consist of vegetables and cheese. Both ends of the spring rolls are gently pinched to seal the filling. Then, it is coated with bread crumbs and deep-fried quickly to keep the vegetables bright and flavorful. Although one spring roll costs € 2, local people enjoy them very much.

- Handmade Recipe

-

Food Ingredient

Corn Starch/All Purpose Flour/Salt/Water/Vegetable oil

How to make

(1) Well mixed corn starch, all-purpose flour, salt. (2) Add water into the bowl and keep stirring until the lumps are gone. (3) Heat up a pan with low heat. (4) Use a paper towel or brush to apply a layer of oil over the pan. (5) Pour batter into the pan. (6) Lift and swirl the pan immediately to spread the batter evenly. (7) When the edge peels away from the pan, flip the wrapper over and cook for a few more seconds. (8) Remove the wrapper from the pan and set it aside.

- Downloads

English

English