Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

This client has been operating a food factory in South Africa for over 30 years, specializing in high-quality frozen foods, including samosas, rollups, and waffles. With strong brand recognition in the local market, the client first visited ANKO’s booth at the IBA exhibition for an initial consultation. At that time, they had no immediate need for automation and did not pursue further contact. A year later, as their existing product sales stabilized, they decided to develop a new product. After conducting market research, they discovered that Meat Pies are highly popular in the region. This led them to reconnect with ANKO to explore automation solutions. With our professional assistance, we customized unique patterns for their Chicken Pies, successfully differentiating their products in the market and enhancing their brand identity.

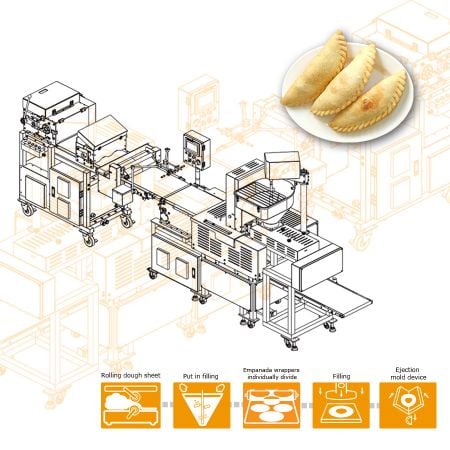

ANKO developed the high-capacity EMP-3000 Empanada Making Machine based on a client’s requirements in the United States. Our team conducted an in-depth analysis of operations at the client’s facility to understand the challenges of their Empanada production. This client needed a machine that could “quickly adapt to market demands while maintaining a high-quality product output.” After multiple test runs and refinement, the ANKO EMP-3000 Empanada Making Machine was launched. This model has a capacity of producing 3,000 Empanadas per hour to help clients’ productivity while saving on labor costs. The easy-to-remove filling system enables continuous production and improves quality control, providing a competitive advantage in food manufacturing.

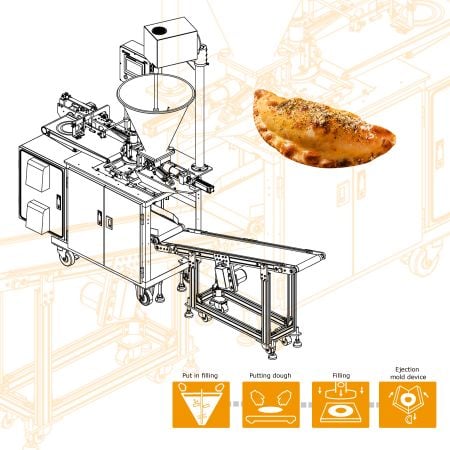

ANKO has found there is an increasing demand for Empanadas in the World marketplace. ANKO’s research has determined that this phenomenon not only exists in Spain and Latin American countries, but also in the USA, Canada, Australia, and the Philippines. And as a result, there is a great demand for automated Empanada machines. ANKO has been approached by many companies and different clients seeking a machine that can process high fat content dough such as puff pastry in order to make Empanadas. Currently, ANKO’s HLT-700 Multipurpose Filling and Forming Machine can produce Spanish style Empanadas with the capacity of over a thousand pieces of products per hour using a variety of forming molds. ANKO’s new EMP-900 Empanada Making Machine is our latest design for making Empanadas with high fat content pastry dough. ANKO’s team has devoted much time researching and developing our Semi-automated Clamping Mold Device, and it was tested using ANKO’s client’s recipe from the USA. This machine has successfully produced Empanadas that can be either baked or deep-fried and fulfilled ANKO’s client product specifications.

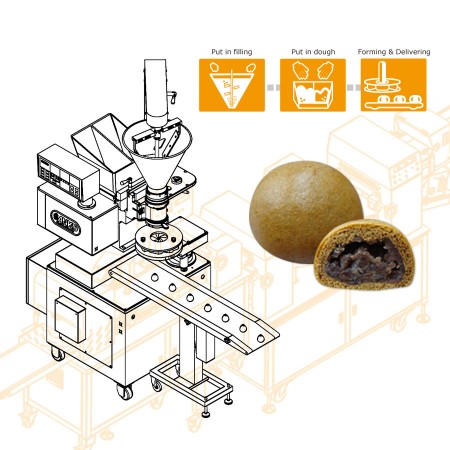

This company owns a bakery, selling various buns and bread. Brown sugar is a common ingredient in Asian cooking, and many people consider it to be healthy food. The client develops a stuffed bun which dough is added brown sugar and which only weighs 12-15g. Since they started selling brown sugar steamed buns, the great popularity has made them hard to handle so many orders. Knowing ANKO is the expert in designing food processing equipment, they contacted us for solutions.

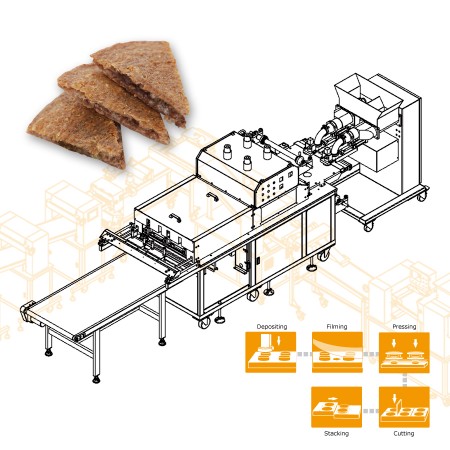

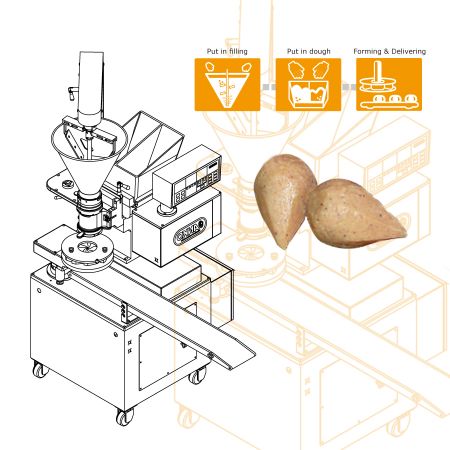

The manual production of Kubba Mosul Pastry relies on a large amount of labor. The ingredients for making pastry and filling must be prepared separately; in addition, shaping a flat circle takes complex steps. Many Middle Eastern immigrants in western countries cannot forget the taste of hometown. Therefore, the market not only in Middle East but also in western countries, there have been marked growing needs for the manufacture of many Kubba Mosul products. A lot of clients hoped to have an automatic Kubba Mosul machine, so that ANKO has kept that in mind and carried out the new project development.

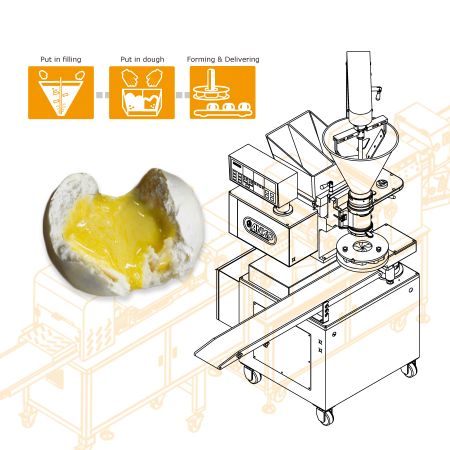

The dining group operates Cantonese restaurants, hot pot buffets, and Japanese buffets for satisfying various consumers. They used to make their food products by hand. With more and more restaurants opened, the continuing growth in demand for steamed custard buns in all types of their restaurants prompted the company to invest in a new machine to extend its offerings. it's a turn to transform handmade into automatic production. Chefs hoped to maintain food quality while cutting cost so that they found ANKO. We have the largest market share in Taiwan food machine industry and our machine can help them meet the growing demand. After testing our SD-97W, they are satisfied with the multifunctional encrusting and forming machine which offers them the flexibility in production. In addition to steamed custard bun mentioned above, they also use the machine to produce sesame balls.

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online, in supermarkets or deli. Selling products in multi sales channel had leaded to an increasing demand, so the company's owner, via a dealer, had been looking for a supplier who can offer an automated production solution for making kubba. It's always a challenge to make a machine work well with a new recipe. In this case, we had a problem in forming kubba because the crust was too sticky. The just formed kubba would stick to the shutter unit and then be broken while the shutter unit opened. Through recipe and temperature adjustment, ANKO team solved the problem successfully.