Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

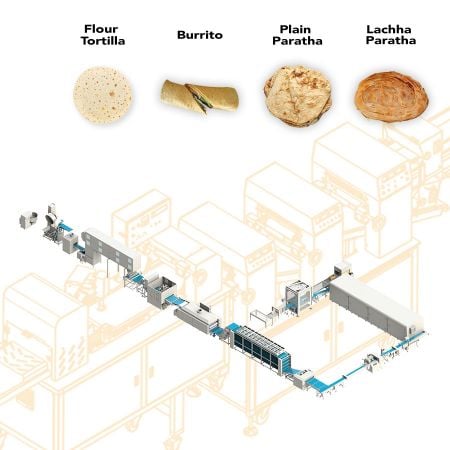

ANKO has newly configured four Integrated Production Lines to meet the manufacturing needs of Flour Tortillas, Burritos, Plain Parathas, and Lachha Parathas. More than 1.5 billion people worldwide consume these products, representing a major global market. Globally, medium-sized food manufacturers make up the majority of the industry. However, when faced with surging order volumes, labor shortages, and mounting competitive pressure, these businesses often need to transition toward scaled and automated production. Flatbread production is more complex than other foods, requiring consistent quality and efficient output. ANKO’s solution integrates dough feeding, forming, packaging, inspection, carton sealing, and environmental monitoring into one streamlined system—helping clients upgrade their production with ease.

This client has been operating a food factory in South Africa for over 30 years, specializing in high-quality frozen foods, including samosas, rollups, and waffles. With strong brand recognition in the local market, the client first visited ANKO’s booth at the IBA exhibition for an initial consultation. At that time, they had no immediate need for automation and did not pursue further contact. A year later, as their existing product sales stabilized, they decided to develop a new product. After conducting market research, they discovered that Meat Pies are highly popular in the region. This led them to reconnect with ANKO to explore automation solutions. With our professional assistance, we customized unique patterns for their Chicken Pies, successfully differentiating their products in the market and enhancing their brand identity.

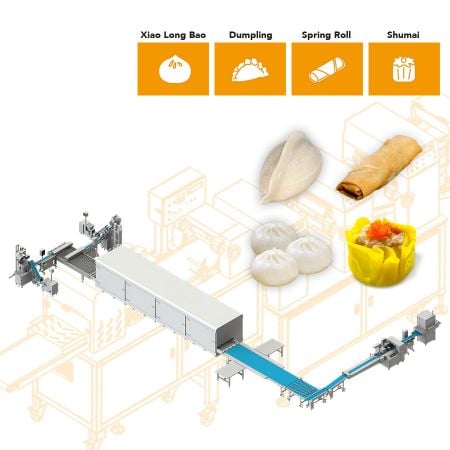

The global food market is rapidly changing. When peak seasons arrive, urgent orders always come quickly. When facing global labor shortages and ever-changing consumer tastes, food companies are eager to find more flexible and efficient production models to respond to market demand. ANKO's newly launched "Integrated Production Line" is designed to resolve the difficulties associated with food manufacturing. Our newly designed production lines include Dumplings, Shumai, Spring Rolls and Xiao Long Bao, providing everything from feeding systems, forming machines, to packaging and various inspection equipment. ANKO's streamlined labor configuration has a daily output of 150,000 pieces! We can also provide solutions for other food products, configuring appropriate production equipment to optimize efficiency and implement a smooth integrated transition.

An ANKO client operates a baking factory in the Netherlands and exports their baked goods to various European countries, including the UK, France, Germany, and Luxembourg. Recently, this client ventured into the production of Chinese Dim Sum and learned about ANKO through local food industry contacts. Due to our excellent reputation, professional expertise and quality service in the industry, we successfully created an automated Har Gow production line for making high-quality Har Gow that met the client’s expectations.

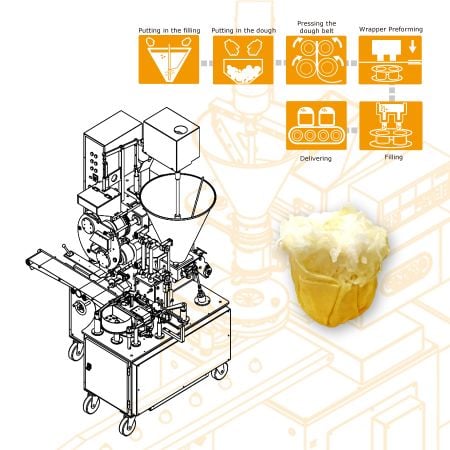

The client has a central kitchen to produce and sell shumai to retailers and takeaways. The growing demand and labor costs prompted him to find an automation solution. Through his friend's introduction, he knew that ANKO is a professional food machine manufacturer. When he visited us for machine test, we used radish shreds in substitution for cassava shreds because cassava is not common in Taiwan. It's also an unprecedented attempt for us. Finally, we were glad to succeed in producing radish shumai by our shumai machine and earned recognition from the client.

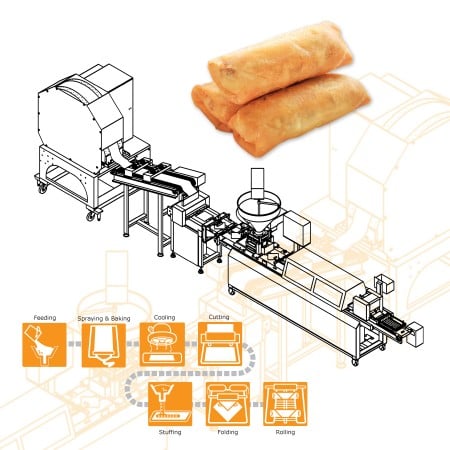

The client runs restaurants, Indian food retail stores, and food factories at the largest Indian community in Birmingham, UK. Their major consumers are the Indians in the UK. Years ago, the client bought a food machine from ANKO. Without a machine trial before purchase, its user-friendly design, intuitive operation, and stable production and ANKO's services gave him a great impression. Therefore, he placed another order for spring roll production line this time because he thinks ANKO is reliable. (The SR-24 is no longer available. The new model is SR-27 machine.)