What Things to Consider When Setting up a New Lachha Paratha Production Line

In order to increase capacity and improve product quality, the idea of shifting manual to automatic production has been lingering in your mind but you just don't know where to start. Then, you start searching on the Internet. You might find many consulting firms; you might find a lot of food machine companies including ANKO. You might be wondering which kind of company you should call. We have our own factory, so we know making a complete factory plan is important to improve efficiency. Therefore, we offer not only a machine but also consulting services. When your inquiry comes in and our sales clicks on, we assure you can follow us to have a forming machine that suits your needs and front- and rear-end equipment, recipe, machine trial, training and after sales services.

Lachha paratha

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. How to plan lachha paratha factory layout?

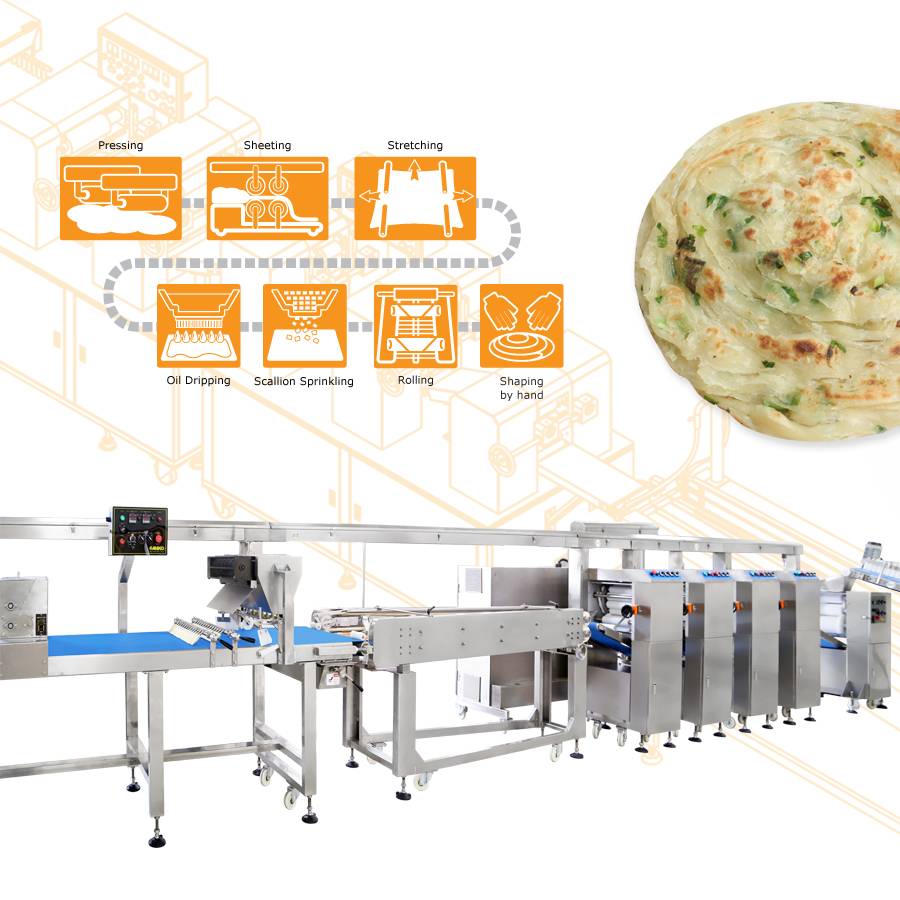

If you have no experience in factory planning, you only need to provide a 2D drawing layout in .DWG (AutoCAD file format), we would take the manufacturing process, production line, and building facility into considerations as laying out your factory.

And here is some information about setting up ANKO's Lachha Paratha & Green Scallion Pie Production Line (LAP-5000) that you might need to know.

Space requirement

The lachha paratha production line is a large-scale production line suitable for food factory. The entire length is 22 meters, but you don't need a 22-meter long factory. We can customize the line layout from I-line into L-line or U-line.

Factory design

Having a room for resting dough and a room for placing an oil melting tank is highly recommended.

Oil melting room

The machine designer equips the production line with an oil melting tank for keeping oil in a liquid state. If the tank is put on the side of the production line, dropped oil is easy to make the floor dirty and cause the staff to slip and fall. Taking into account environmental hygiene and safety, we suggest setting up an oil melting room beside the production line. Or we can help you fit a pipe between the production line and melting room.

Dough resting room

The coiled lachha paratha dough balls need a rest to prevent shrinking after pressing. Therefore, a dough resting room with temperature control is quite important.

In addition to the rooms mentioned above, other common facilities include raw material warehouse, raw material preparation area, dishwashing area, packaging room, walk-in refrigerator, drain, etc., all of which depend on your needs.

Machine installation and wiring guide

Wiring and other requirements of machine installation and suggestions will be provided in advance. For example, ANKO's LAP-5000 requires electrical wiring and/or oil pipe. If you also order a rear-end machine for filming and pressing such as ANKO's PP-2, then electrical wiring and an air compressor are needed.

Solution 2. What equipment do I need?

The LAP-5000 production line starts from pressing and sheeting a chunk of dough and makes the dough end up lachha paratha dough balls. Therefore, for preparing the dough, you will need several mixers (the number of mixer depends on your needs and the mixer's capacity). After the lachha paratha dough balls get a rest, PP-2 is an ideal machine to complete both processes of pressing and packing with plastic film. To achieve maximum efficiency of LAP-5000, it is recommended to have three pieces of Filming and Pressing Machine working with a LAP-5000.

ANKO offers not only forming machines but also front- and rear-end equipment to save you time on planning and money on delivery costs.

Solution 3. How to know if buying the machine is a good investment?

To determine whether it is a good investment, you may also want to know how long it takes for your investment to recover and what returns you should expect from your investment. We can make a rough estimate according to the price of the machine, the throughput and price of your products. Moreover, if you could provide further information about electricity costs and raw material costs, we can measure the ROI for you, let you have more confident in this investment.

Solution 4. Can the LAP-5000 make my lachha paratha without changing its texture and taste?

Only by making products with a machine, cooking and tasting the products can you ensure the texture and taste of the products satisfy needs. Therefore, ANKO offers a machine trial service and well-equipped food lab for cooking and tasting. If don't like the taste and texture, our experienced food researcher can help you make them better. You can visit our Taiwan headquarters in person or have a remote trial. Take an example of the production line and lachha paratha, flour is the key ingredient affecting taste. We suggest bringing or sending the flour you usually use so that you may know the actual taste.

Solution 5. What kind of after sales service do you offer?

You might be worried that you have nowhere to turn to for help when a machine operates abnormally or stops. ANKO's machines carry one-year warranty. ANKO will provide new components for replacement as long as machine breakage isn't caused by misuse of users. When the machine has exceeded the warranty period, you can still buy spares and components from us.

For replacement or repair, depending on your needs, we can provide "how to replace" video for you or arrange an engineer to visit you.

To prevent sudden failure, we highly suggest that you should schedule regular machine inspection to ensure machine parts are properly maintained and replaced.

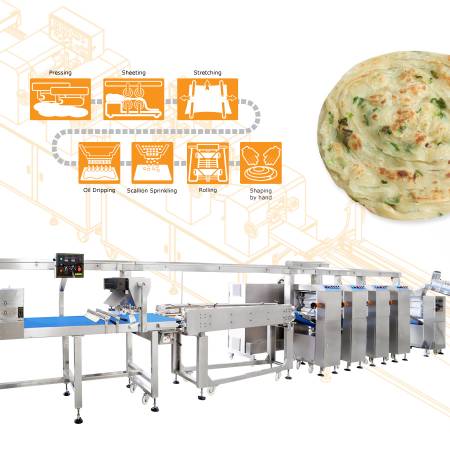

Food Equipment Introduction

- Feeding

- Pressing and sheeting

- Stretching

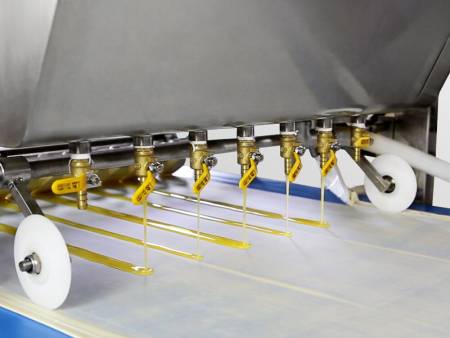

- Oil dripping

- Sprinkling

- Rolling

- Dough resting & Oil solidifying

- Pressing and dividing

- Rolling

More efficient dough feeder

The dough feeder consists of a work table, a conveyor, and a sensor, designing to replace manual dough feeding and making more flexible and effective deployment of staff. The work table with appropriate height helps workers to prepare and move dough onto the conveyor easily. Through the incline conveyor, the workers won't struggle to move kilos of dough to the entry on top of the pressing device. And at the entry, a sensor is equipped to control the feeding speed.

Extremely thin layer

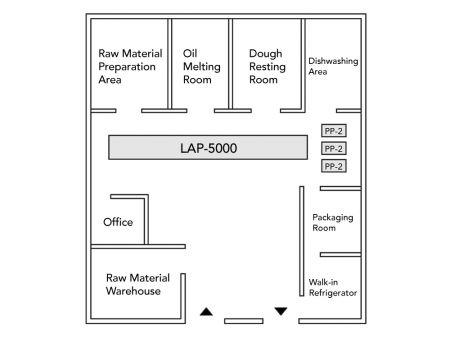

Rolling out the dough into a sheet, and folding the sheet into a strip, then coiling the strip is the process to make layered and flaky flatbread.

The design of LAP-5000 follows the process. It has a special stretching device to gently pull out the dough belt into a 0.8-millimeter thin sheet, thus it can save you and your cooks rolling out dough balls repeatedly. Then, the extremely thin sheet is formed into a strip and rolled up into dough balls with delicate folds which give your lachha paratha or scallion pancakes a flaky texture after pan-frying.

Automatic oil feeder with temperature controller

Oil is an inevitable ingredient of layered flatbread. The LAP-5000 production line is equipped with an automatic oil feeder with temperature controller, which can keep oil in a liquid state at 40℃ and prevent the feeder from blocking. Also, separately-controlled oil nozzles allow you to adjust oil volume.

- Solution Proposal

ANKO's High-Efficiency Lachha Paratha Production Solution Drives Revenue Growth

ANKO did

ANKO has assisted clients from over 114 countries globally by offering Comprehensive Production Planning, Professional Consultancy, and Guidance, leading to successful businesses in the Lachha Paratha food market and the establishment of numerous high-quality food production solutions, including food factories and central kitchens.

ANKO can help you more

In addition to the LAP-5000 Lachha Paratha Production Line, ANKO also provides a One-stop Lachha Paratha Production Solution. This solution encompasses dough mixers, sheeting and wrapping machines, packaging equipment, and food x-ray inspection machines, creating an integrated, highly efficient production line that maximizes revenue.

For more inofrmation, please click Learn More or complete the form below.

- Machines

-

LAP-5000

The LAP-5000 Lachha Paratha & Green Scallion Pie Production Line is designed to produce the lachha parathas and scallion pancakes with extremely thin layers. It can make 2,100 - 6,300 pieces per hour, only needs 3 persons to operate. One person feeds dough and ingredients and two persons collect products.

- Video

- Category

- Downloads

English

English