Successfully produced Crispy Vegetable Spring Rolls! ANKO configured an Automatic Spring Roll Machine for a client in Canada

In Canada, the frozen food market is in the keen competition. Locals prefer buying take-out foods or instant foods to save time. The client runs chain restaurants and receives frozen food orders from supermarkets. Because of increasing demands, except for the original machine they bought from ANKO for making wonton, fried dumpling, shumai and the like, they would like to purchase spring roll machinery for expanding their production lines. (The SR-24 is no longer available. The new model is SR-27 machine.)

Spring Roll

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. How to keep cabbage crisp in a vegetable Spring Roll without mincing it.

This client is meticulous about keeping the cabbage in Spring Rolls crisp. If they kept the cabbage stems in large pieces, it would affect the filling extruding process and cause the final products to vary in weight and be loosely wrapped. Shredding the cabbage would also not meet the client’s product texture requirements. ANKO’s experienced engineers came up with a solution to… (Contact ANKO now for more information.)

Solution 2. How to perfectly form vegetable Spring Rolls using automated machineries?

When producing vegetable Spring Rolls with automated machines, the vegetable filling can often be over processed, dehydrated, and lack viscosity, which makes it difficult to wrap each roll perfectly. To solve these issues, ANKO’s engineers used… (Contact ANKO now for more information.)

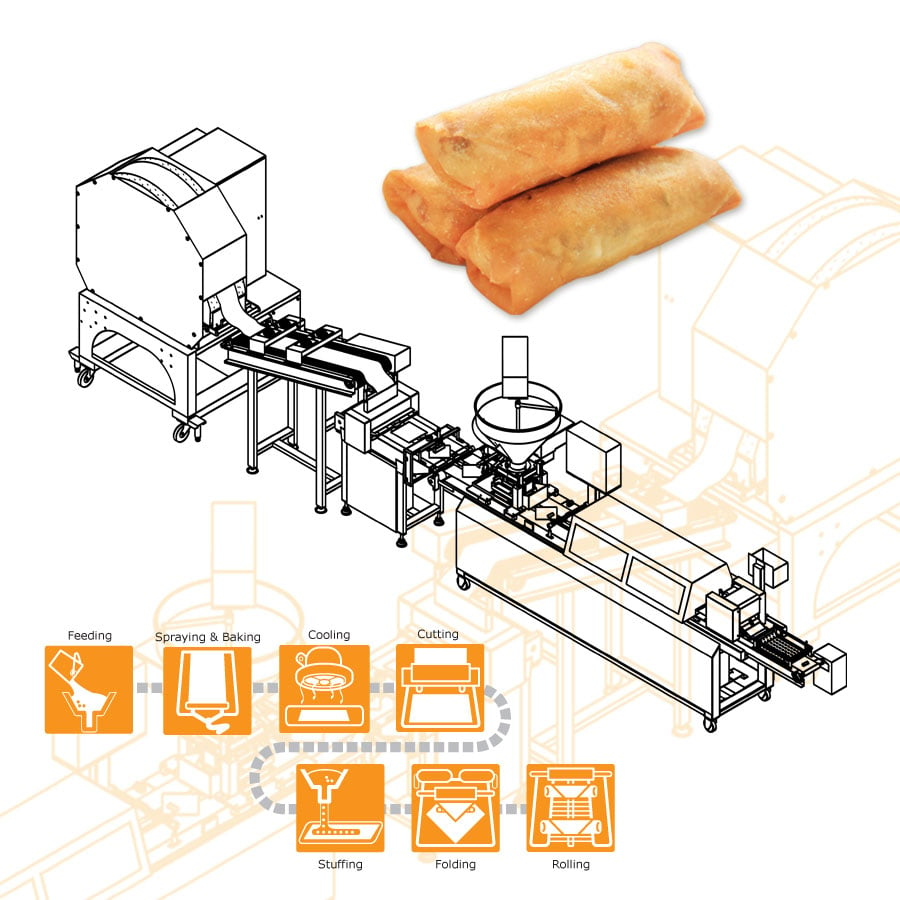

The automated filling system in the Spring Roll machine ensures that the vegetable filling is accurately extruded onto the wrappers, then each is folded, and wrapped into perfectly formed Spring Rolls.

Food Equipment Introduction

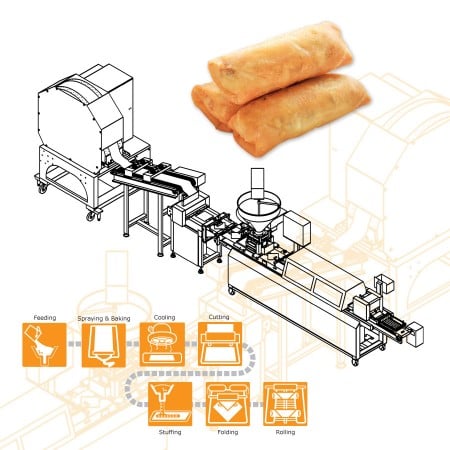

- Pour cooked stuffing into hopper.

- Pour mixed batter into batter tank.

- Set the temperature.

- Bake wrapper belt.

- Cool wrapper belt under fans.

- Cut wrapper belt into 200mm*200mm squares.

- Turn cut wrapper in position, ready to be fed with stuffing.

- Extrude stuffing: locate stuffing on a set place.

- Fold wrapper: fold the first corner to the center to cover the stuffing, and then seal the stuffing by left and right side flappers.

- Apply glue: apply batter on the last corner as glue.

- Roll up: roll up toward the last corner under rolling net, at the same time, seal the end.

Automatic Spring Roll Machine with Superior Filling System Designs

Every client brings their premade filling and/or recipes to ANKO to conduct a Spring Roll production evaluation run. In this case, the client’s vegetable filling lacked lubricity and would get stuck in various parts of the machine making it impossible to complete the filling and forming process. ANKO is very experienced in building commercial food machines; our engineers incorporated a filling auger, scrapers, and unique designs to create a superior filling system for the Spring Roll Machine. These innovations ensured that the machine can process various ingredients, including large pieces of vegetables like cabbage, carrots, and mushrooms, viscous cheese filling, sweet taro pastes, apple preserves, and bananas to make perfectly formed and delicious Spring Rolls.

- Solution Proposal

Simplify Your Spring Roll Business with ANKO's High-Quality Equipment

ANKO did

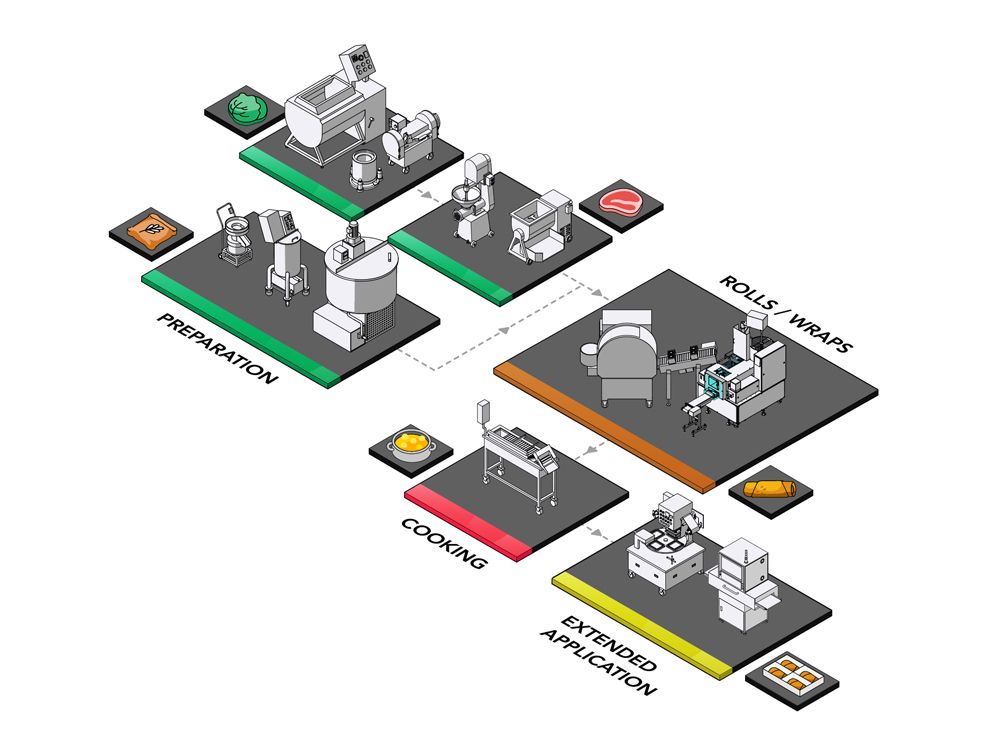

Vegetable Spring Rolls are gaining traction, driven by the rise of plant-based and vegan diets. ANKO's Spring Roll Production Line is versatile, accommodating vegetables, meats, mixed fillings, and even sweet options like cheese. The Spring Roll's size is customizable to your needs.

ANKO can help you more

For a seamless automated production process, ANKO offers a One-stop Spring Roll Production Solution, featuring a batter mixer, vegetable cutter, meat grinder, forming and rolling machines, packaging equipment, and food x-ray inspection systems for maximum efficiency. Additionally, ANKO can integrate commercial freezer equipment to enhance sales and profits in your frozen food business.

If you are interested in ANKO's Spring Roll Production Solution, please click Learn More or complete the form below.

- Machines

-

SR-24

SR-24 spring roll production line hourly produces 2400 pieces. The high productivity is referred to a chain of producing process. First of all, the dough belt is made by a big baking drum and cooled immediately by fans. The temperature of baking drum and the thickness of dough belt are easy to control, even the size of pastry can be cut as required. Then, the stuffing depositing machine is connected after the cutter unit. Through a sensor, spring roll stuffing will be deposited on wrappers at the right time. Finally, the unique folding device and stainless net is efficient to form spring rolls. (The SR-24 is no longer available. The new model is SR-27 machine.)

- Country

Canada

Canada Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Canada with advanced automated food production technology for making Spring Rolls and Wontons. We also offer integrated solutions for popular foods such as Empanadas, Samosas, Pierogi, Dumplings, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Canada has a large Asian population, and their diets have been greatly influenced the modern Canadian food culture. "Spring Rolls" are one of the many foods introduced by Chinese immigrants, and similarly, "Lumpia" was brought from the Philippines. Both are popular in many local restaurants, and take-outs establishments in Canada. Spring Rolls have also become a common dish often shared at family gatherings and festivities.

Many restaurants and caterers serve traditional Spring Rolls and offer various innovative, savory, and sweet rolls to satisfy consumers' cravings. Frozen and ready-to-eat packaged Spring Rolls are also sold at numerous retail stores and wholesale markets for consumers to enjoy at home. There are also vegetarian and vegan Spring Rolls, as well as deep-fried, baked, and steamed Spring Rolls catering to consumers' diverse and often healthier tastes.- Handmade Recipe

-

Food Ingredient

High-Gluten Flour/Water/Oil/Salt/Cabbage/Carrot/Glass Noodles

For spring roll wrapper

(1) Mix high-gluten flour, water, and salt together. Well stir them until there are no lumps. (2) Smear some oil on a fry pan. (3) Pour batter in the fry pan and swirl the pan to make batter evenly cover the pan. (4) When sides of spring roll wrapper slightly peel off, apply a spatula to slowly turn over it. (5) Fry the other side for a few seconds and leave it in a plate. (6) Follow the steps above to cook the rest of wrappers.

For spring roll filling

(1) Soak glass noodles in water until soft. (2) Shred cabbage, carrot. (3) Fry them together.

Wrap spring rolls

(1) Scoop filling and put on a corner of a wrapper. (2) Fold the corner first, and the right and left side corner. (3) Then, roll it up.

After all spring rolls are done. Finally, deep fry them.

- Downloads

English

English