ANKO's EMP-900 Empanada Making Machine – Designed for producing Empanadas made with high fat content dough

ANKO has found there is an increasing demand for Empanadas in the World marketplace. ANKO’s research has determined that this phenomenon not only exists in Spain and Latin American countries, but also in the USA, Canada, Australia, and the Philippines. And as a result, there is a great demand for automated Empanada machines. ANKO has been approached by many companies and different clients seeking a machine that can process high fat content dough such as puff pastry in order to make Empanadas. Currently, ANKO’s HLT-700 Multipurpose Filling and Forming Machine can produce Spanish style Empanadas with the capacity of over a thousand pieces of products per hour using a variety of forming molds. ANKO’s new EMP-900 Empanada Making Machine is our latest design for making Empanadas with high fat content pastry dough. ANKO’s team has devoted much time researching and developing our Semi-automated Clamping Mold Device, and it was tested using ANKO’s client’s recipe from the USA. This machine has successfully produced Empanadas that can be either baked or deep-fried and fulfilled ANKO’s client product specifications.

Empanada

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. A Big Break Through! EMP-900 can Produce Empanadas with High Fat Pastry Dough

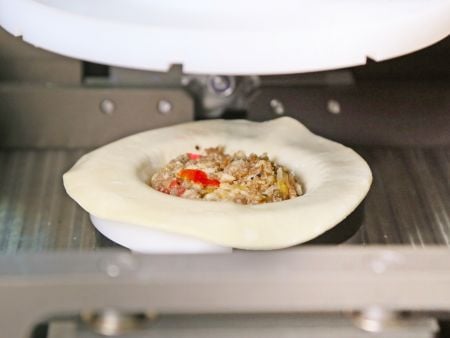

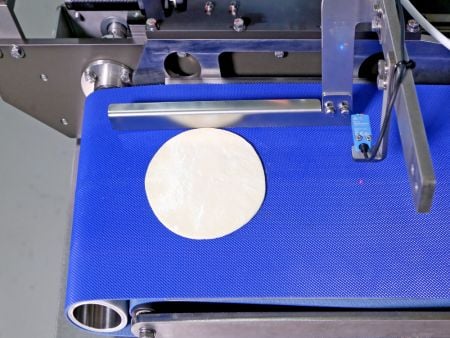

ANKO’s EMP-900 Empanada Making Machine is easy to operate. The automated production starts by placing premade dough wraps onto a conveyor belt. ANKO’s team tested many different recipes using solid fats, water, and flour to form the dough that make the Empanada wrappers and finalized recipes containing an oil water solution that contributes as much as 75% of the weight of the dry ingredients. ANKO’s team tested them baked and deep-fried Empanadas with this new recipe, then recorded the appearance, weight, finally cutting the Empanadas in half to observe the filling and how the ingredients look. A final taste test was done, and the finished products were evaluated. During the R&D process, ANKO has tested and adjusted the recipes as well as the design mechanism until the results met all our client’s expectations.

Solution 2. Clamping Mold Device designed to form Empanadas

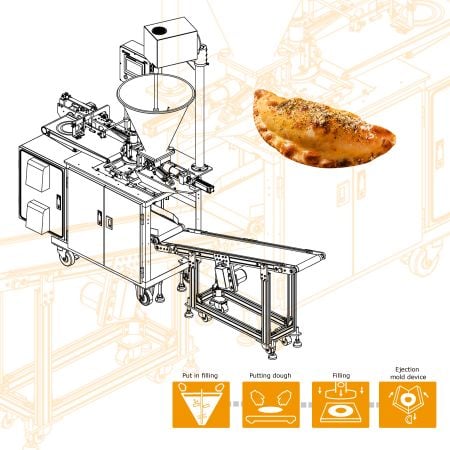

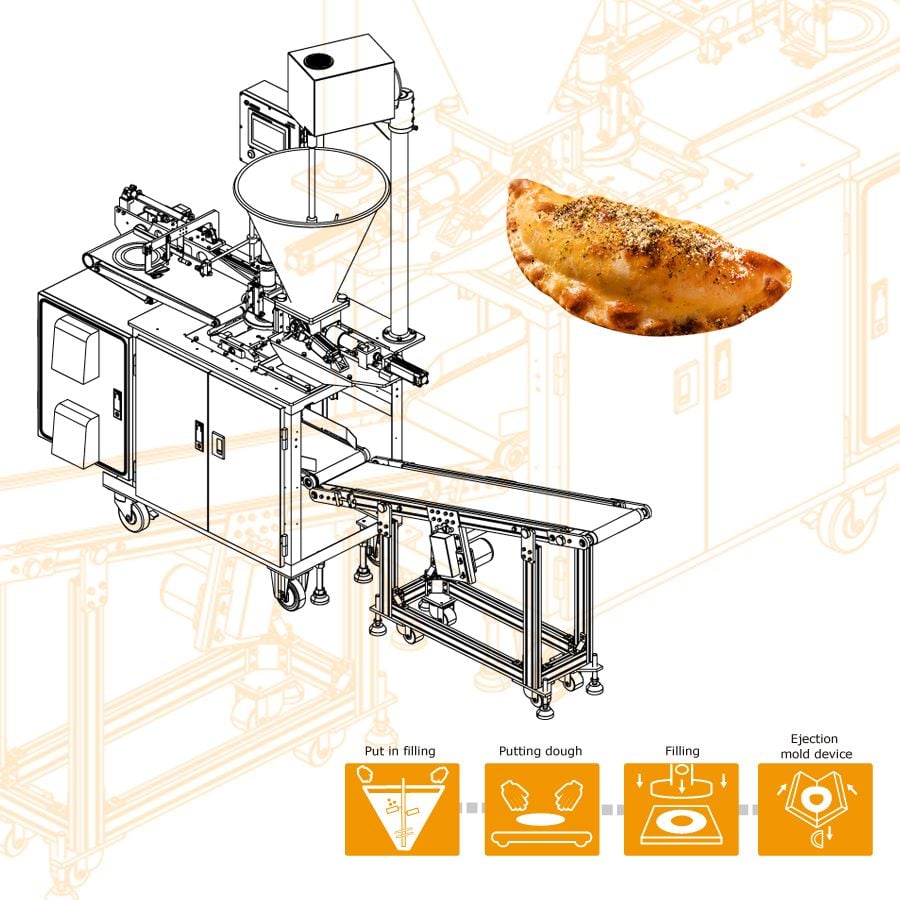

Most Automated Empanada machines form products using molds with a circulatory system that is rather complicated and the finished products are dropped on the conveyor. Another method uses a reciprocating mechanism that is uncomplicated, and the final products can be picked up where it is formed. ANKO’s EMP-900’s design combined the best of both systems, so that each Empanada is filled, formed and then the Ejection Mold Device will remove the product to be placed on the conveyor belt with ease. ANKO’s Ejection Mold Device is Patented (Patent No.111204597)

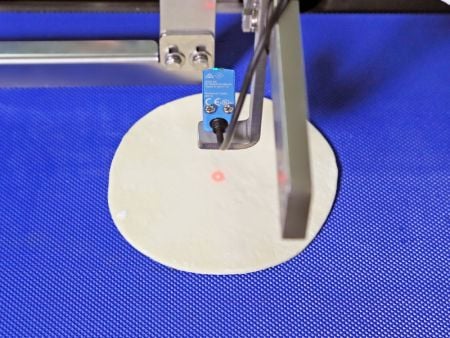

Solution 3. A Design Using Infrared Sensor and Guiding Tools to Ensure Empanada Wrappers are Placed correctly

EMP-900 is a semi-automatic Empanada Machine that requires the already-made wrappers to be placed on the conveyor belt manually. To ensure this process can be done precisely every time, ANKO’s R&D team used an Infrared sensor to calculate the exact spot to extrude the filling. After vigorous production testing, our engineers installed a guiding tool to the conveyor to ensure wrappers are placed correctly, and repeatedly. The production process runs smoothly, and with consistency ensuring the products made flawlessly.

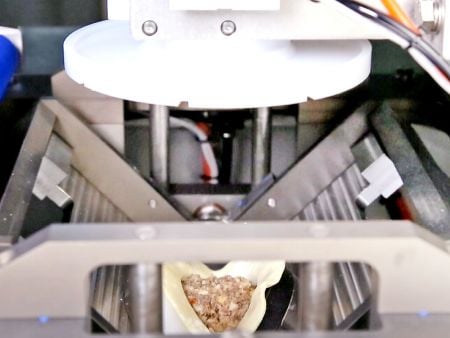

Solution 4. An improved extruding system keeping all of the filling ingredients intact

Beef and chicken are the most common proteins used in making Empanadas, and they are often mixed with potatoes, corn kernels, and peas, that are often smashed or damaged during the automated production. EMP-900 uses a special auger that can process diced ingredients as large as 1 cubic cm, and it has an intermittent rotation mechanism that is only triggered when the infrared senses a dough wrapper. This ensures it will not over mix the filling and help maintain the consistency of the filling throughout the production process. The improved extruding system processes raw or cooked ingredients with different moisture contents.

The auger has an intermittent rotation mechanism to prevent over mixing and pressing of the ingredients

Effortlessly Produces Empanadas with High Fat Pastry Dough – ANKO’s EMP-900 Empanada Making Machine has a maximum productivity of 900 Empanadas per hour, and it only requires two employees to operate. One person places already-made wrappers onto the conveyor, and the other person can sort the Empanadas at the end of the production line. Additionally, it also takes just 2 simple steps to change the molds to produce products with different prints, which increases product line output and work efficiency. Click on the link below to see how Empanadas can be made effortlessly with ANKO’s Machine. Our subsidiary office in Los Angeles offers on-site product testing services, and our experienced engineers can offer you professional advice on how to improve your products. We sincerely welcome you to contact us for more information or to schedule an appointment.

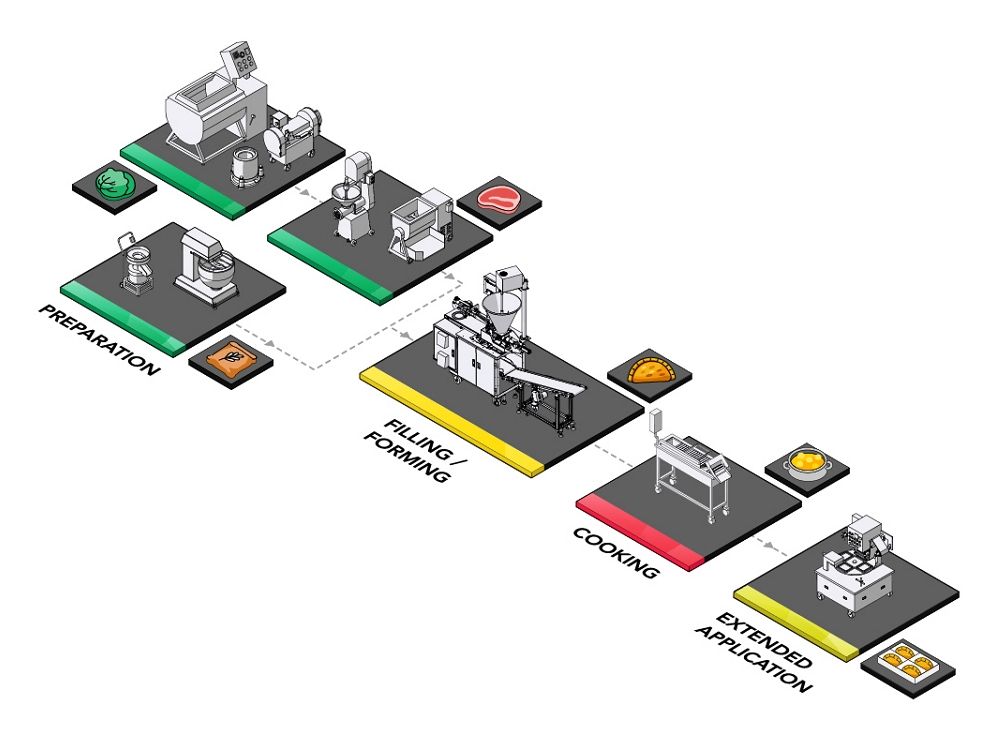

Food Equipment Introduction

- Place pre-made dough wrappers on the conveyor belt

- Wrapper being maneuvered onto the Clamping Mold Device

- Filling automatically extrudes onto the wrapper and is formed into Empanadas

- The final product is removed from the mold with an Ejection Mold Device

- Further processing or packaging can be done manually

Best Empanada Production Equipment for Small to Medium Sized Businesses resulting in Cost Effective Production

When making Empanadas by hand, it takes time to weigh and make sure the dough and filling ratio is consistent, not to mention the pleating or printing process that requires expert techniques. To produce 900 pieces of Empanadas may require 3 to 5 skilled employees and that labor is expensive. ANKO’s EMP-900 is designed for easy operation and requires only 2 entry level employees with no extensive training or experiences (productivity may depend on the individual working at the production line). This machine can produce enough Empanadas to supply small food factories, central kitchens, stand-alone restaurants, and food trucks. ANKO can also assist our clients with production planning and procurement services including commercial dough mixers, sheeters, fryers, and ovens to create a complete production line. (Note: Actual productivity always depends on the Empanada recipe, product size, thickness of the wrapper and other variables.)

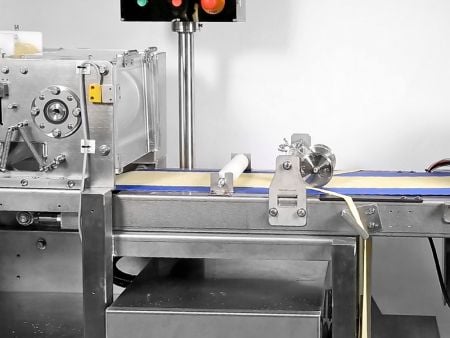

A Dough Sheeting Cutter is designed to automatically divide the pressed dough sheets into individual wrappers and place them onto the conveyor belt without an operator. And a Dough Recycling System can significantly reduce overall food waste and costs.

- Solution Proposal

Empanada Production Solutions to Help You Manufacture and Deliver Quality Empanadas

ANKO did

With the newly launched EMP-900 Empanada Making Machine, small to medium sized food manufacturers can produce Empanadas with ease. It requires only 2.5 square meters/26.9 square feet for storing.

ANKO can help you more

Besides EMP-900, ANKO can also offer Vegetable Cutter, Meat Grinder, Dough Mixer, Conveyor Fryer, Packaging Machine and Food X-Ray Inspection Machine to help our clients build a complete production line. Based on your requirement, our team can provide you with the best Empanada production solution to ensure smooth operations.

If you are interested in ANKO's Empanada Production Solution, please click Learn More or complete the form below.

- Machines

-

EMP-900

ANKO’s new EMP-900 Empanada Making Machine is designed to process high fat dough using a recipe made with an oil water solution that contributes as much as 75% of the weight of the dry ingredients. It can process various raw or cooked ingredients with different consistencies to produce great tasting Empanadas. The unique extruding mechanism can keep ingredients such as corn kernels and diced shrimp intact. It also comes with molds that produce many different prints; ANKO also offers customized molds with business logos or specialty designs. ANKO’s EMP-900 is a semi-automated machine that only requires two employees with basic skills to operate, and it has a maximum capacity of 900 pieces per hour. This is no doubt this is the BEST equipment for small to medium sized food business aiming to successfully produce high quality Empanadas.

- Country

United States

United States Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in the United States with advanced automated food production technology for making Dumplings, Egg Rolls, Empanadas, Spring Rolls, Burritos, Mochi, Quesadillas, and Spring Roll Wrappers. We also offer integrated solutions for popular foods such as Samosas, Momo, Pierogi, Tortillas, Shumai, Tapioca Pearls, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.To provide timely and localized service, ANKO has established a branch office in the United States. With a dedicated team based locally, we’re able to offer in-person consultation, machine demonstrations, and responsive after-sales support tailored to the specific needs of our American clients.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Empanadas originated in Spain, and then they were introduced to most countries in the Latin America, and to the rest of the world. Empanadas are considered a popular appetizer, finger food, or quick snack in Latin American countries and most parts of Southern Europe. Empanadas are similar to dumplings made with a dough wrapper and filled with various types of fillings. The most popular ones being beef and chicken, and the final products are then either baked or deep fried. Every year, on the 8th of April, it is “International Empanada Day” and many Empanada enthusiasts make their own or enjoy Empanadas at restaurants or eateries; often sharing their enjoyment of different empanadas on social media. Recently, Empanadas have gained much popularity in the United States, being served from food trucks and food vendors in New York, New Jersey and they are especially popular at Carnivals and Food Truck Festivals. It seems that everyone in the food industry is eager to make the best Empanadas and enjoy a successful business.

Traditionally, Empanada’s main ingredients were meats, but recently many cheesy Empanadas are being made with seafood, lobster meat, and these new versions have become very popular. There are also numerous different vegetarian Empanadas being made with potatoes, mushrooms, tofu, and mixed vegetables, catering to people who do not eat meat or have dietary restrictions. Finally, there are also sweet Empanadas made with fruit fillings such as apples, bananas, black cherries, caramel, and cinnamon flavored that are all delicious.- Handmade Recipe

-

Food Ingredient

For dough-All-purpose flour/Baking powder/Unsalted butter/Cold water/Sugar/Salt, For filling-Garlic/Shallots/Potatoes/Carrots/Red bell peppers/Crushed tomatoes/Water/Beef stock/Ground beef/Soy sauce/Raisins/Sugar/Fish sauce/Salt/Pepper

Making Dough

Mix all-purpose flour, baking powder, sugar, and salt together with unsalted butter by hand, then slowly mix in cold water to form a dough and let the dough rest overnight in a refrigerator

Making Filling

(1) Mince garlic, chop red onions, potatoes, carrots, and bell peppers (2) Stir-fry all the vegetables with cooking oil in a large pan or pot (3) Then add diced tomato, water, and beef stock to the pan or pot and bring it to a boil (4) Add soy sauce, raisins, fish sauce, pepper, sugar, and salt to season the mixture, and slowly simmer for another 20 minutes (5) Add ground beef into the pan or pot and cook for another 30 minutes until the sauce thickens (6) Turn off heat and let the cooked beef filling cool and then place it in a refrigerator for at least 2 hours

Assembly

(1) Take the dough out from the refrigerator and let it rest for 30 min at room temperature (2) Roll the dough into a long log and then divide it into 2–3-inch balls (3) Round each dough ball by hand and then roll it flat into a wrapper with a rolling pin (approximately 3mm thick) (4) Take chilled beef filling out and place a spoon full on top of the wrapper (5) Fold the empanada and seal it with pleats or a fork (6) Finally, deep-fry the empanadas till golden brown and serve

- Downloads

English

English