Automatic Dumpling Production Equipment Designed to Enhance a Food's Handmade Look

Customers want to increase production capacity by moving from manual to automatic production. However, sometimes machine-made dumplings cannot meet their required shape. Either customers have to give up having handmade pleats and delicate patterns or they stay in manual production. Dumpling machine has been ANKO's bestseller. We have received many inquiries about dumpling shapes. "Do you have other more natural patterns?", "Do you have pinching patterns?", "Do you have other pinching patterns?", "Why is the machine-made dumplings not mouth-watering?" and so on. To response these demands, we started a series of development processes.

Dumpling

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. From design to reality, a human-centered design process of "handmade dumpling" forming molds.

It's been a long time since HLT-700XL was launched. During these years, we are dedicated to developing a machine to solve customers' problems rather than to make them have new problems. Therefore, ANKO's R&D team adopts "design thinking", focusing on user experience, instead of mechanical functions. Through 5 stages of design thinking – empathy, define, ideate, prototype, and test – we want to develop a product that meets customers' needs.

Phase 1 – Empathy

There was a lot of feedback from our clients.

"Is the shape of machine-made dumpling as same as that of handmade dumpling?", "Except for these kinds of patterns, are there any options?", "It's easy to recognize machine-made dumplings."

About end consumer's preferences:

"I still love handmade dumplings.", "Let's buy some handmade frozen dumplings.", "The handmade dumplings are full of filling, very delicious."

Dumpling manufacturers or restaurant owners worry that the shape of dumpling affects consumers' appetite and willingness to buy. Most people even think that handmade dumplings are more delicious than machine-made ones.

Phase 2 – Define

Dumpling manufacturers or restaurant owners want to satisfy most consumers' needs to maintain or increase sales, so we have to offer a dumpling machine that can make dumplings with a handmade look. Our R&D team, therefore, set the target of developing a set of forming molds that could make plump dumplings with realistic pinching patterns.

Phase 3 – Ideate

At this stage, first of all, our forming mold designers had done a thorough survey on dumpling shape and different ways to fold dumplings. Then, everyone threw out their ideas that helped team members think from different viewpoints, such as engineering, characteristics of cooked or uncooked dumpling wrapper, consumer's preferences and needs. Finally, the ideas were integrated into several types of forming molds.

Phase 4 – Prototype

After having specific ideas, the designers made prototypes of the forming molds with a 3D printer. At the fourth stage, our R&D team made many prototypes and went through a continuous process of testing and modifying. Due to the testing process, the ideas had been gradually actualized. The designers developed "Artisan Mold", which consists of two molds to form "plump dumplings" and innovated three pinching pattern molds, one can make dumplings with "handmade pleats" and the other two can make them with "thin edge" and "wave edge".

Phase 5 – Test

Finally, these molds were installed on HLT-700U and had test runs to ensure whether they can produce dumplings as required. Our R&D team also tried different setups to find subtle problems and solve them.

On the day of the HLT-700U launch event, these innovative molds are received positive responses. A customer told us that she had wanted to have a HLT-700XL for years, but had yet to make a decision. This time, she saw that the HLT-700U can make such plump dumplings, she knew that it is what she wants.

The HLT-700U's main features: The new Multipurpose Filling & Forming Machine - HLT-700U - is capable of mass-producing dumplings with handmade pleats, full filling, and an attractive shape. The Artisan Mold is an innovative design to enhance the dumpling's handmade look.

ARTISAN Molds Series - ANKO's ARTISAN Series is tailor-made for HLT-700U Multipurpose Filling And Forming Machine. ARTISAN Series includes Thin Edge, Handmade Pleats and Wave Edge Mold.

Food Equipment Introduction

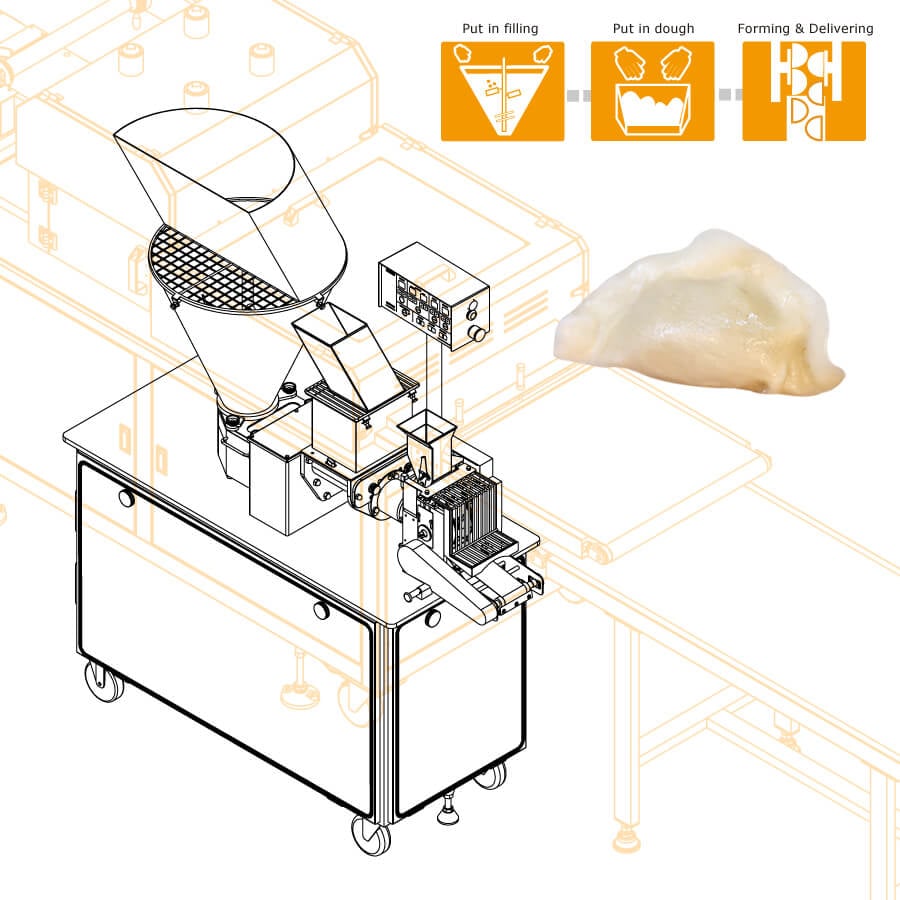

- Dough is extruded into a dough tube.

- Filling is extruded and filled in the dough tube.

- The filled dough tube is formed into dumplings.

Pinching pattern with handmade pleats

The design concept of the pattern comes from a dumpling folding way - holding a dumpling in your palms and pressing it to seal with two thumbs. Our designers researched the marks, edge thickness, and curved lines after pressing and then carefully designed the details of the mold. Dumplings formed by this mold features realistic handmade pleats, appropriate thickness, and natural curved lines.

Pinching pattern with thin edge

The design inspired by a kind of Taiwanese noodles which edges like waves. The mold is designed to press very thin edge, in order to make the edges of dumplings curve after cooking.

- Solution Proposal

ANKO introduces the industry first “Integrated Dumpling Production Solution"

ANKO did

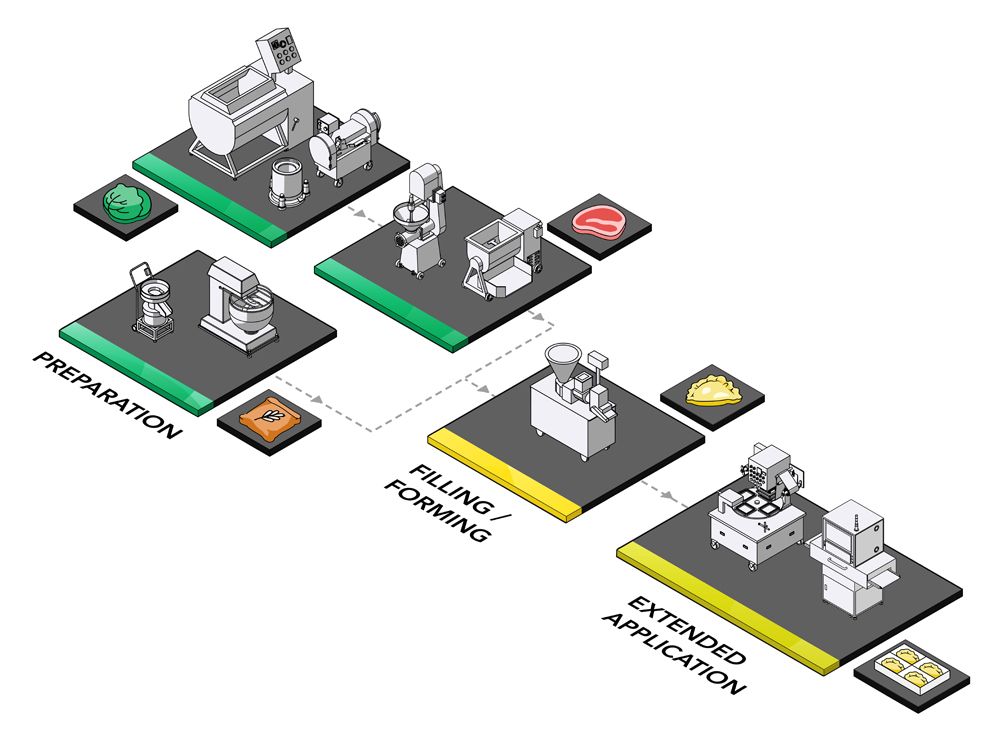

The HLT-700U Multipurpose Filling and Forming Machine is our main product which can be configured with a commercial food processor, meat grinder, and dough mixers for food prep, as well as a X-Ray Inspection machine and packaging equipment to build an integrated production line based on your specific production requirements.

ANKO can help you more

Our seasoned professional consultants can also assist you with labor allocation, factory planning, and production workflow management. Additionally, we have more than 16 regional agents and distributors to provide you with professional and local services.

If you are interested in our Dumpling Production Solution, please click Learn More or complete the form below.

- Machines

-

HLT-700U

In addition to the innovation of molds, both dough and filling systems of the new HLT-700U Multipurpose Filling and Forming Machine have been optimized to make the production of food more stable and efficient. For example, an HLT-700U equipped with Artisan Mold can make 12,000 pieces of 25-gram dumplings per hour.

Being a pioneer in the food machinery industry, ANKO has upgraded our HLT-700U Multipurpose Filling and Forming Machine to include a built-in Internet of Things (IoT) system to provide real-time access to data monitoring to manage production better remotely. This technology enables accurate production forecasts before the peak season, ensuring smooth manufacturing, optimized production yield, and efficiency. In the past, machine maintenance and repairs were done manually; now, they can be scheduled through advanced data collection and analysis. ANKO’s system monitors the vibrations of machine to prevent unexpected mechanical problems and significantly reduces machine downtime. It also lowers risks and repair costs while giving our clients more time to focus on food production. For more information, please feel free to contact us.

- Country

Taiwan

Taiwan Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Taiwan with advanced automated food production technology for making Dumplings, Potstickers, Noodles, Shumai, Scallion Pies, Steamed Custard Buns, Tapioca Pearls, and Sweet Potato Balls. We also offer integrated solutions for popular foods such as Baozi, Wonton, Spring Rolls, Pineapple Cakes, Xiao Long Bao, Tang Yuan, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Traditionally, people eat dumplings at special occasions like Chinese New Year. Dumpling consists of a dough wrapper wrapped around a filling. On Chinese New Year's Eve, one of the lucky dishes is dumpling, because when wrapping filling, good luck is also wrapped into dumplings. All people who eat the dumplings can have good luck in the coming year. For this reason, on that day, every family will make dumplings, starting from kneading dough and preparing ingredients of filling. All family members sit around a table and wrap dumplings together. It is always a great time and memory when it comes to dumplings.

Now, dumpling becomes a food eaten as a meal at any time. When you want a quick meal or don't know what to eat, you can buy a bag of frozen dumplings from supermarkets. Boil water, drop dumplings, and 10 minutes later, enjoy them! Or you can have several pieces of cooked dumplings at a little eatery. A dish of dumplings is paired perfectly with soy milk or soup. Some people like to have dumpling soup that dumplings are served in a bowl of soup such as hot and sour soup (酸辣湯) or beef soup.

In addition to the two ways to have dumplings, due to the growth of food delivery in recent years, dumpling delivery to your door is another choice. Perhaps the rising trends would increase the consumption of dumplings.- Handmade Recipe

-

Food Ingredient

For Wrapper-Flour/Water/Salt, For Filling-Ground Pork/Corn Kernels/Scallions/Ginger/Salt/White Pepper/Soy Sauce

Making the Wrapper

(1) Add flour, water, and salt in a large bowl, then stir them together. (2) Knead and press the dough until smooth. (3) Rest for one hour.

Making the Filling

(1) Chop scallions and ginger. (2) Add ground pork, corn kernels, scallions, ginger, salt, white pepper, and soy sauce in a large bowl, and stir the filling well. Set aside.

How to make

(1) Roll the dough into a long, cylinder shape. (2) Equally divide the dough into small balls. (3) Roll out the dough ball into a thin wrapper with a rolling pin. (4) Spoon filling on the center of wrapper. (5) Smear water on the edge. (6) Fold it in half and tightly press the seam. (7) Pleat the edge. (8) Repeat last five steps to wrap all dumplings.

- Downloads

English

English