ANKO Customized a Layered Paratha Production Line for a Bangladeshi Company

The client had been processing aquatic food products on the beginning of his business and becoming a leader in local food industry. Then, the client established a new plant to produce flour and pastries. Bangladesh is a dense area in which there are tremendous opportunities in the frozen food market. Because paratha is a common food in this area and the client has a flour factory, he decided to run a paratha production line. By word of mouth, they approved ANKO's ability to plan a turnkey. Plus, our advantage is the flexibility of planning production line and installing machine, depending on the client's space. Therefore, they believe in our machines and services, purchasing the whole production line from dough mixer to food packaging from ANKO.

Paratha

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. The installation of some units is flexible to fit the client's factory space.

The client purchased all machines from ANKO for his paratha production line. However, his factory space was limited and freezers were set up. As a result, ANKO reassembled margarine extruder from the left side of machine to the right side. At first ANKO RD team had considered the flexibility of machine installation. Due to the sensible design, the change did not affect production and food quality.

Solution 2. How did ANKO assist a Bangladeshi client to prevent their Paratha dough from breaking and overflowing during the production process?

The standard Layered Paratha Production Line is designed with 3 pairs of pressing rollers that rotate at the same speed; the quantity of dough enters and ejects from feeding rollers that are controlled by the space between two rollers. This client had problems with dough breakage and overflowing during their production process. One problem was due to the speed of the processing rollers, and the other is due to the margarine extruder. When there is an excess amount of margarine or when it is extruded too fast onto the dough, it can cause the dough to break. ANKO’s engineers were able to finetune this process… (Please feel free to contact ANKO for more information on our many innovative solutions.)

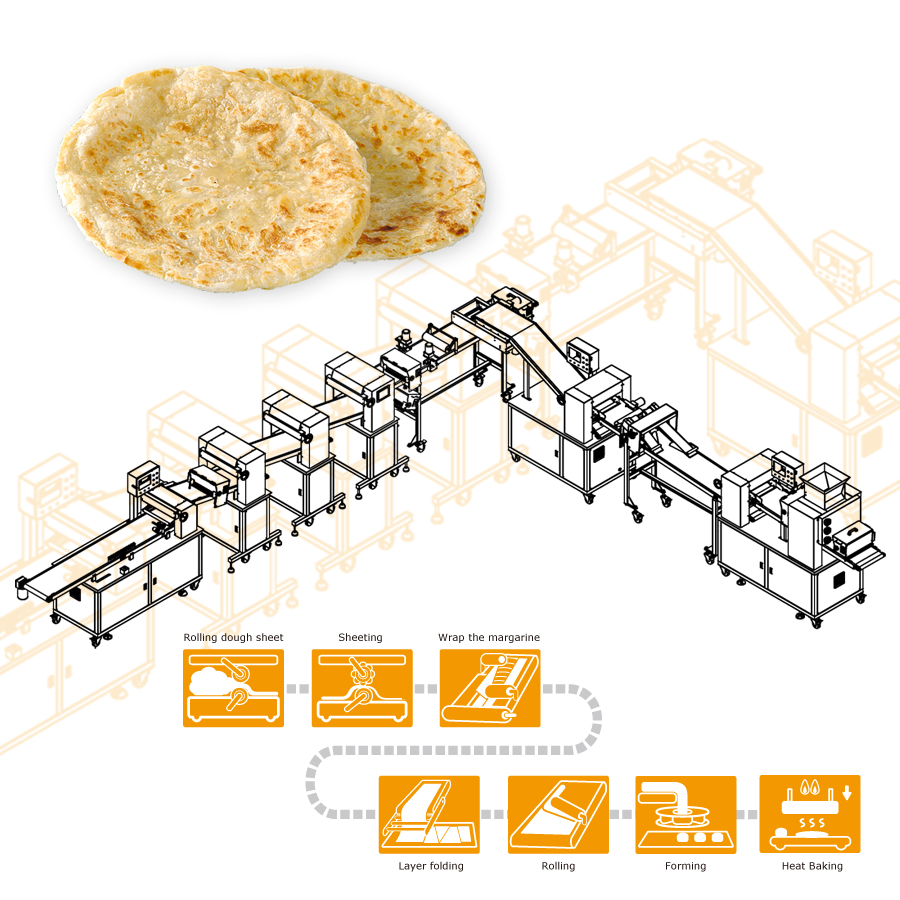

This ANKO Layered Paratha Production Line combines the LP-3001 with the EA-100KA Forming Machine, and the PP-2 Automatic Filming and Pressing Machine, which has the capacity of producing plain, stuffed, or layered Paratha at the rate of 3,000 pieces per hour. It is suitable for medium to large scale food production plants, central kitchens and producers that require sizeable production quantities.

Food Equipment Introduction

- Mix ingredients in a certain ratio, knead them into dough, and put the dough into hopper.

- Press dough into dough belt.

- Continue sheeting into desired thickness.

- Extrude margarine on the center of dough belt. The margarine is about one third of dough belt.

- Fold dough belt from both right side and left side toward center.

- Press dough belt again via sheeting roller.

- Arrange the following conveyor in different direction to fold dough belt forth and back as “Z” to produce paratha layers.

- Press dough belt again.

- Roll up dough belt into a long cylinder.

- Cut into balls via shutter unit.

- Rest dough balls.

- Apply PP-2 automatic filming and pressing machine to cover dough balls with film and press them into flat dough.

- Apply SA-113 continuous-type sealing machine to seal every package.

Fundamental of Design

- Place dough balls on fixed positions that are covered with food wraps.

- Cover dough balls with another food wraps.

- Press dough balls into required size and thickness.

- Cut wraps off.

- Stack up products. The number of products in a pile is adjustable.

What are the tips that machine makes layers of flavor of paratha?

The first tip is to extrude a flake of margarine. The purpose is to evenly wrap margarine in dough belt. In addition, ANKO's Automatic layered Paratha Production Line includes many sheeting roller units. After Z-shaped folding, ...(Please contact us to get more information)

Brilliant ideas of rolling machine of LP-3001

In order to double layers, Automatic Layered Paratha Production Line equips a rolling machine to concentrically roll up layered margarine dough belt. Moreover, how to prevent rolled dough from unrolling? The solution is ...(Please contact us to get more information)

- Solution Proposal

Enhance Your Paratha Production Efficiency with ANKO's Tailored Solutions

ANKO did

With ANKO's extensive expertise, we provide comprehensive solutions to address all production issues that may arise. Our team of professionals is skilled not only in Paratha production but also in other Indian foods like Chapati, Roti, Puri, and Samosa. We understand the intricacies of raw materials and recipe optimization, ensuring your success.

ANKO can help you more

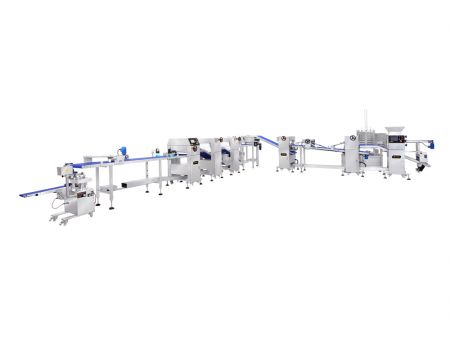

We offer a One-stop Production Solution for Paratha making, featuring a dough mixer, Paratha Production Line for shaping and pressing, packaging machinery, and food X-ray inspection equipment. This integrated solution boosts production efficiency, allowing you to navigate high labor costs and rising wages while maintaining quality.

Before making a purchase, consider our Machine Trial testing, either on-site or via real-time video. Our Taiwanese headquarters houses a fully-equipped 'Food Lab' where recipe fine-tuning and optimization take place. For more details, please click Learn More or contact us through the inquiry form below.

- Machines

-

LP-3001

LP-3001 automatically fills margarine and folds up dough belt multiple times from different direction. The whole making process is designed by imitation of hand gestures. Repeating folding and sheeting as well as rolling at the last stage aims to produce multilayer products with layers of flavor. The optional stuffing machine for installing on LP-3001 satisfy client's requirement to produce many stuffed foods such as croissant, paratha, green-scallion pie, Danish pastry, palmier, etc.

EA-100KA

EA-100KA is suitable for working with different ANKO's machine such as HLT-700 series, LP-3001, etc. to cut a long dough roll into spherical foods or buns with pattern on top. In the case, the client cut the layered dough roll into dough balls. After resting for a while, PP-2 continues the processes of pressing and filming.

PP-2

Automatic filming and pressing machine is flexible to press products with different thicknesses and sizes as required. After cutting into dough balls by EA-100KA, PP-2 will automatically film and press products to prevent dough sticking together. Chinese pancake, paratha, green-scallion pie and the like are suitable for the machine. For the client's convenience, the number of final products in a pile is adjustable to reduce labor cost and prevent mistakes from manual counting.

- Video

The processes of cutting and stacking filmed products - After pressing filmed dough, the products are cut by safety cutter in standard size for stacking easily.

Z-shaped folding and sheeting processes - In order to increase more layers, dough belt is stacked back and forth. Then, it is thinned again, before rolling up. In the video, dough layers and the differences of thickness are obvious.

- Country

Bangladesh

Bangladesh Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Bangladesh with advanced automated food production technology for making Paratha. We also offer integrated solutions for popular foods such as Roti, Momo, Rasgulla, Samosas, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Paratha is a kind of flat, round, layered bread with ghee. But, sometime, it can be triangular or square. Layered paratha has layers of taste, soft inside and crispy outside. If it is a stuffed paratha, the taste would be even more abundant. Cheese, vegetables, or potato are ingredients they usually add as fillings. Side dishes like pickles, vegetable or meat curry, or simply a hunk of butter are the most common ones to eat with paratha. As the food culture spreads to Malaysia, the food similar to paratha becomes their main dishes. And curry is still their favorite dip. To have a mouth of paratha and a mouth of Teh Tarik must be a wonderful savor.

- Handmade Recipe

-

Food Ingredient

Atta/Salt/Ghee/Oil/Water

How to make

(1) Mix atta, salt, oil, moderate water. (2) Knead them into pliable dough. Then, set aside for 30 minutes. (3) Divide the dough into several equal dough balls. (4) Apply a rolling pin to roll a dough ball into 4 inch diameter circle. (5) Smear ghee on the surface of paratha. (6) For making square paratha, fold one side toward center and smear ghee on the surface of folded part. (7) Fold the other side toward center and also smear ghee on the surface of folded part. (8) Then, fold the left and right side toward center to make the shape into a small square. Remember to smear ghee on every folded part. (9) Sprinkle some flour on top and roll the square dough into flat. (10) Repeat the above steps to make several parathas. (11) Heat a tava to cook paratha and keep flipping it over until you see brown flecks.

- Downloads

English

English