Leading the Chinese Food Market in America! ANKO’s Comprehensive Support for Efficient Dumpling Production

This client is a third-generation Chinese American who inherited his grandfather's wholesale food business in the United States. A few years ago, his company had to adjust to accommodate the changes in the overall marketplace and focused on producing and distributing Chinese cuisines. After thorough market research, the client purchased ANKO's HLT-700U Multipurpose Filling and Forming Machine to make authentic Chinese Dumplings. After nearly a year of market testing, which showed promising sales, the client further invested in the ER-24 Automatic Egg Roll Production Line and AF-589 Conveyor Fryer a year later. ANKO's high-quality and durable food machinery has successfully helped clients excel in authentic Chinese food production and become leaders in the market.

Dumpling

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. ANKO Machine with the Precise Recipe Adjustments Produce the Perfect Dumplings for our Clients

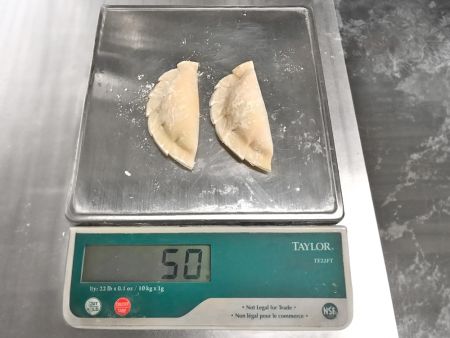

After the Dumplings are made, they undergo cooking, freezing, and deep-frying processes. If the proportion of water in the dough is not well controlled, the wrappers will crack during the final frying process, resulting in a poor appearance of the finished product. ANKO tried two dough recipes; the first used tapioca starch and 41% water; the dough had poor elasticity, yet the HLT-700U multipurpose filling and forming machine can still make Dumplings with this recipe. The second recipe used bread (high gluten) flour and 40% water; the dough was too soft. Finally, ANKO’s experienced professional team considered the local temperature and humidity and adjusted the recipe. The new dough recipe made the perfect Dumplings, with product weight within the expected range. The Dumplings also maintained their intact appearance after various cooking steps.

Solution 2. Comprehensive Technical Support Assisting Clients Develop New Products

This client envisioned expanding their product line from Fried Dumplings to creating new Pork Dumplings and Vegetable Dumplings. After successfully producing the Fried Dumpling, the client needed help making new products with their recipes. The ANKO Food Tech USA team went to this client’s factory and identified critical steps that were lacking in filling preparation. Because the client wanted to make Dumplings with an all-vegetable filling, the HLT-700U Multipurpose Filling and Forming Machine would require additional adjustments on the Filling Screw and Rotor to… (Contact ANKO for detailed information)

Our professional team provided an on-site demonstration and helped our client create the Dumpling products that met their taste expectations. ANKO’s extensive experience in food machinery and our comprehensive pre and post-purchase support continue to build our strong reputation and high level of trust in the industry.

In this case, we custom-created exclusive Dumpling molds with specific sizes and shapes for our client. After the production trials, the capacity reached 8,000 Dumplings per hour, sufficient for the client to meet their market demands.

Food Equipment Introduction

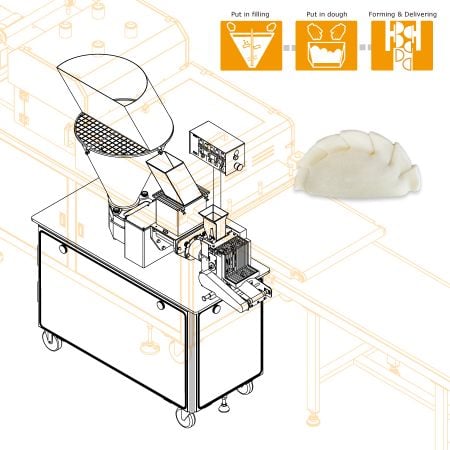

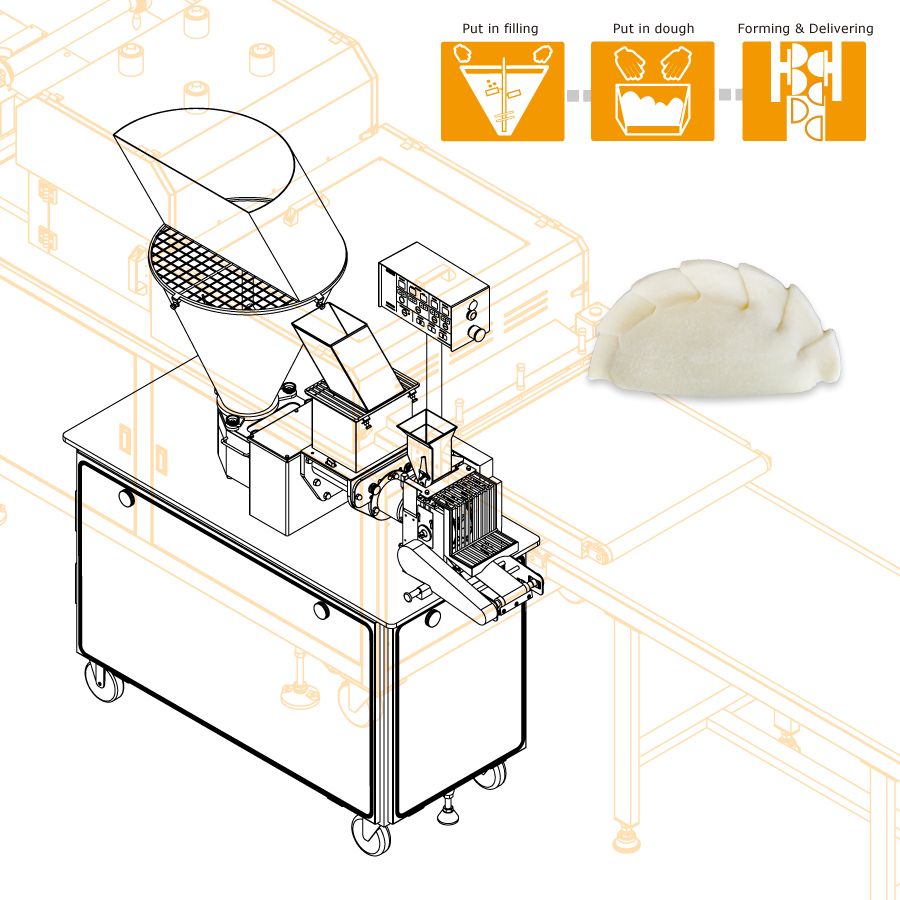

- Load the hopper with premade dough

- Load the hopper with premixed filling

- The machine automatically makes Dumplings

Customized Forming Molds Tailored to Create Diversified Business Opportunities

The key to best-selling Dumplings is more than the taste and textures, but also their appearances! ANKO has garnered unanimous praise from our customers worldwide for our Dumpling production equipment. We have developed more than 300 Dumpling-forming molds and provide customized mold designs to help clients create recognizable products and new business opportunities. Our machines can produce Dumplings from 2 grams to as large as nearly 200 grams per piece. In addition to standard Dumpling shapes, we have created unique shapes such as animals, heart-shaped, flowers, alphabets, numbers, and more. The sizes, weight, wrapper thickness, pleat prints, and wrapper-to-filling ratio can all be evaluated, tested, and customized. ANKO’s goal is to help companies seize various business opportunities and excel in competitive markets.

- Solution Proposal

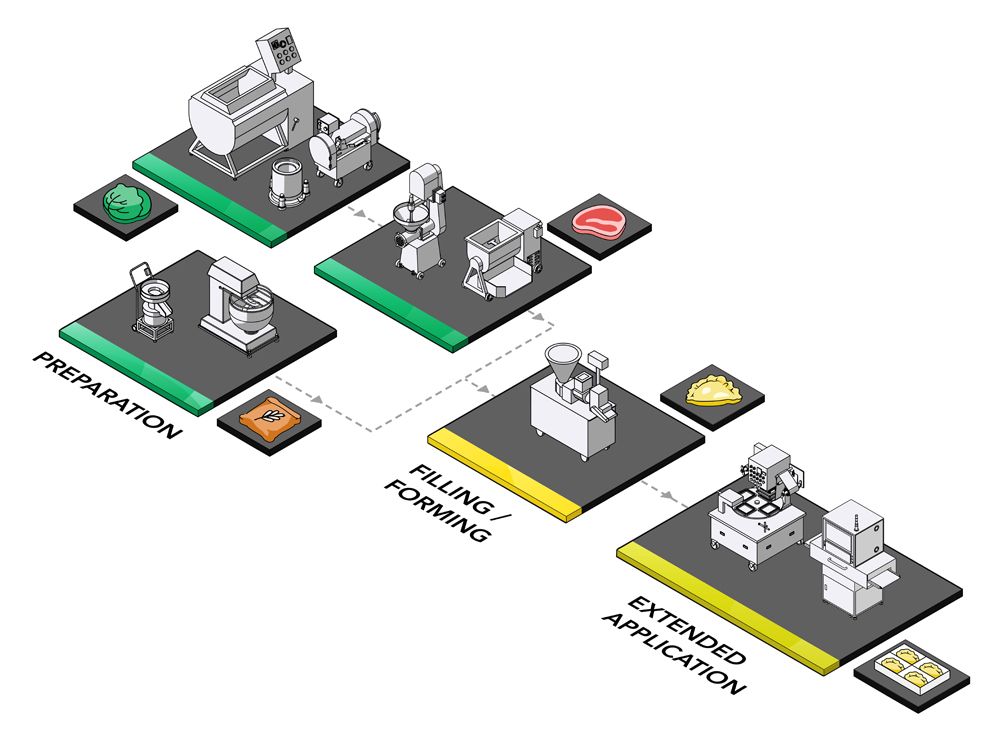

Comprehensive Dumpling Production Solution: Improved Yield and Quality!

ANKO did

This ANKO Dumpling production solution includes commercial food preparation equipment, product forming, extended application like product weighing, packaging, and X-ray inspection machines. We also offer comprehensive equipment installment to help food manufacturers reduce production costs while significantly increasing production output. Additionally, ANKO's automated food machines are customizable to meet client requirements and connect all machines to create a highly automated and efficient Dumpling production line.

ANKO can help you more

ANKO's consultation process is simple and convenient. Our professional team creates tailormade automated Dumpling production solutions and provides production trials, recipe consultation, and customization before the purchase. We also offer training, recipe optimization, after-sales support, and equipment health checks as required. Click on Learn More or complete this inquiry form below, and we will provide you with a customized production solution.

- Machines

-

HLT-700U

ANKO's most popular Dumpling machine "HLT-700U Multipurpose Filling and Forming Machine," adopts brand new design mechanisms to create plump and artisanal Dumplings that look handmade and retain the textures of the filling ingredients, including larger pieces, low fat, and higher fiber content fillings. Various rolling molds are available to create Handmade Pleats, Wave Edges, or unique shapes such as Cherry Blossoms, Heart-shaped, Animal-shaped, etc. These molds provide clients with more options, and we also offer customized designs to meet different product specifications. The machine has a production capacity of 12,000 pieces per hour, and each Dumpling can weigh from 13 to 100 grams each. When both filling and dough are efficient, only one person is required to operate the entire line. Additionally, the built-in IoT system allows real-time and remote production status monitoring; it will automatically detect the status of parts requiring maintenance to avoid unwarranted shutdowns and improve production management efficiency.

- Country

United States

United States Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in the United States with advanced automated food production technology for making Dumplings, Egg Rolls, Empanadas, Spring Rolls, Burritos, Mochi, Quesadillas, and Spring Roll Wrappers. We also offer integrated solutions for popular foods such as Samosas, Momo, Pierogi, Tortillas, Shumai, Tapioca Pearls, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.To provide timely and localized service, ANKO has established a branch office in the United States. With a dedicated team based locally, we’re able to offer in-person consultation, machine demonstrations, and responsive after-sales support tailored to the specific needs of our American clients.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Chinese immigration to the United States began in significant numbers during the mid-19th century and with this influx diverse culinary traditions were introduced. Dumplings are particularly iconic and have become a hallmark of Chinese cuisine. There are various ways to cook and enjoy Dumplings: either boiled, pan-fried (known as Gyoza or Potstickers), steamed, or even deep-fried. Chinese restaurants and fast-food chains in the United States usually offer Dumplings. Many Asian supermarkets, specialty stores, and wholesale food stores also have frozen Dumplings in stock in their freezers. Typical fillings include cabbage, chives, and corn mixed with ground pork, chicken, or shrimp. Innovative flavors, such as XO sauce, scallops, and spicy Sichuan-style fillings, have gained popularity, and some brands have also introduced unique dipping sauces for a customizable dining experience.

Many brands emphasize food safety and quality to build consumer trust and stand out among numerous Dumpling brands. For example, the packaging often highlights Dumplings that are "Made in the USA" or labeled with "No MSG Added," "Plant-Based," "All Natural," or even "USDA Organic." This branding appeals to health-conscious consumers. The rise of social media has also played a significant role in increasing dumpling consumption. Influencers sharing creative ways to enjoy dumplings are attracting younger consumers in the U.S. marketplace.- Handmade Recipe

-

Food Ingredient

Wrapper: Flour/Water, Filling: Ground pork/Shrimp/Minced ginger/Soy sauce/Shaoxing wine/Salt/White pepper/Cabbage/Spring onion/Sesame oil

Preparing the dough

(1) Mix flour and water together to form a dough. (2) Knead the dough until smooth, then place it in a bowl to let it rest for 2 hours. (3) Sprinkle some flour on a work surface, knead the rested dough on it for 3 to 5 minutes, and then let it rest for another 30 minutes.

Preparing the filling

(1) Mix ground pork, shrimp, minced ginger, soy sauce, Shaoxing wine, salt, and white pepper together in a bowl, and then store it in the fridge before use. (2) Shred the cabbage and sprinkle it with some salt, mix well, let it rest for 10 to 15 minutes, and then remove any excess water. (3) Remove the seasoned pork mixture from the fridge, and then incorporate cabbage, chopped spring onion, and sesame oil. Mix well and set aside.

Dumpling assembly

(1) Roll the dough into a thin log and then divide the dough into small equal pieces. Flatten each piece of dough and then cut with a cup into round wrappers. (2) Place a spoonful of filling in the center of the wrapper. (3) Wet the rim of the wrapper and then tightly seal the filling to form the Dumpling.

- Downloads

English

English