ANKO Multipurpose Filling & Forming Machine – Machinery Design for Taiwanese Company

The client runs an eatery next to a school. Two people in total have to be in charge of all works. Due to the fact that more and more people patronized the eatery, the labor shortage prompted him to develop machine production. However, high productivity was not his priority so that he ordered a set of HLT-660 series, which is within budget and enough to achieve his hourly capacity around 5000 pieces. After purchasing the machine, they prepare ingredients in the morning and then arrange production around noon, cooking after taking an order, which can satisfy a large demand during peak hours. (Note: HLT-660 series is no longer available. Please contact us for the updated HLT-700 series.)

Dumpling

ANKO Team Research Problem Solving or Solution Delivery

Dough tube wrinkles, which was probably caused by speed differences between machine units.

As we mentioned above, stuffing and dough tube extrusion speed, mold rotating speed are modifiable by clients themselves. We also provide training when installing machinery. However, they usually forget how to modify the parameters as needed, or their new employees don't exactly take over jobs from former employees. Therefore, ANKO offers complete after-sales service on training.

In this case, Our engineer took opportunity of replacing parts to give on-site training again. Firstly, he explained basic principles and operated machine to help staff understand the function of each parameter, and then demonstrated machine with different parameter settings and compared the finished products. Secondly, he let staff operate machine in person to modify the speed of three units according to different recipes. After they thoroughly understood machine operation, they could modify the parameters to maintain high-quality products in taste and appearance, even though the characters of dough might be changed by other factors.

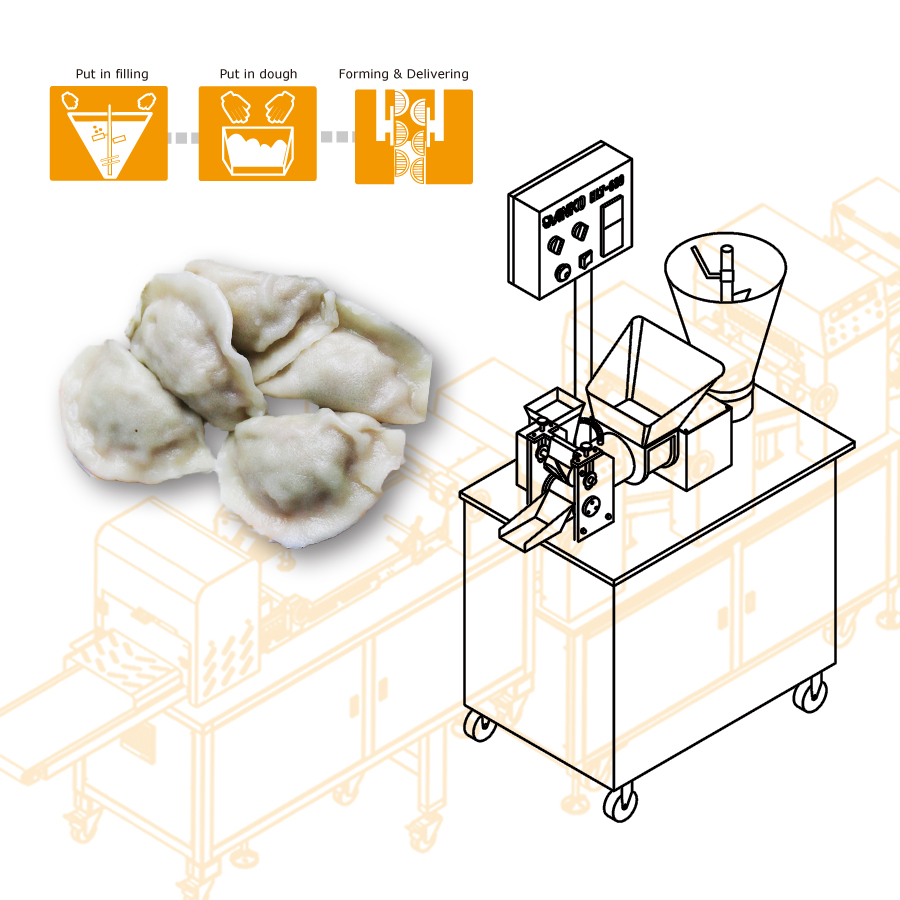

Food Equipment Introduction

- Pour stuffing into stuffing hopper.

- Pour dough into dough hopper.

- Extrude cylindrical stuffing from stuffing pipe.

- Extrude dough tube from dough pipe.

- Fill stuffing into dough tube while stuffing and dough are extruding (step 3 and 4).

- Form products as desired by the cutting of forming mold.

- Scrape every product from lower roller by a scrapper.

- Line up finished products on conveyor for packing or cooking.

According to the characters of dough, the speed of stuffing and dough tube extrusion as well as rotary cutter is adjustable.

With the differences of temperature, humidity, and raw materials, the characters of dough will never be the same. Due to the circumstances, depending on client and market demands, we provide machine test service to adjust machines and ingredients for clients at ANKO headquarters. However, even if we offer such comprehensive service, the parameter setup might not be suitable as they go back to their countries because the characters of dough change. As a result, the parameters of stuffing and dough extrusion speed and forming mold running speed are adjustable flexibly. Clients can modify the parameters in accordance with dough formation to achieve product standardization. From the first one to the last, they all look like the same one.

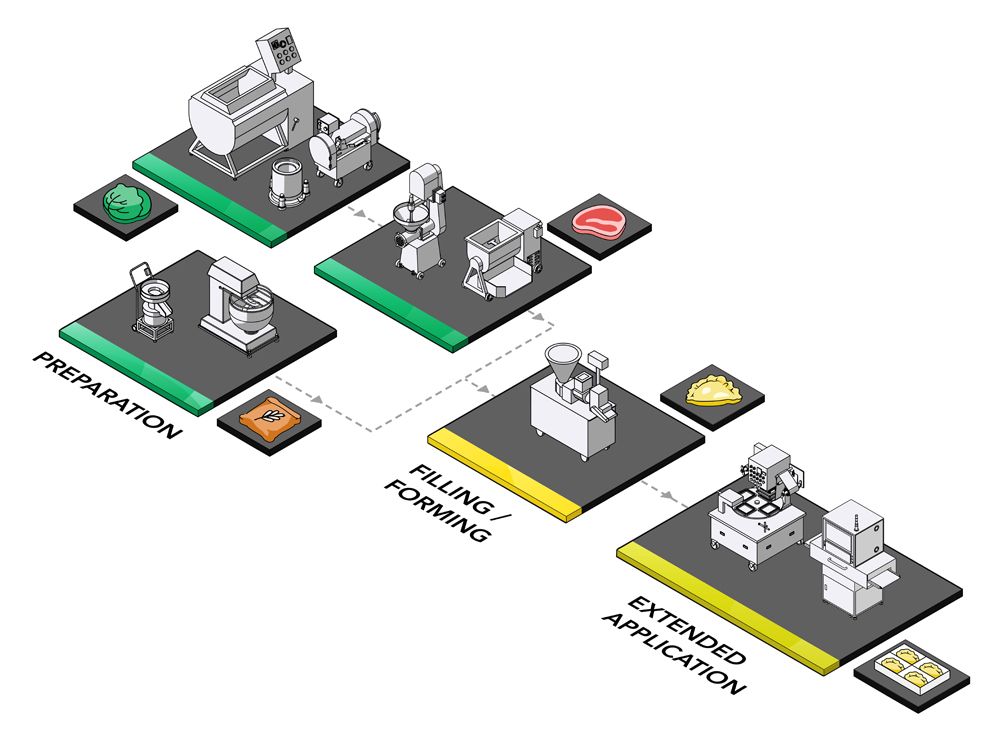

Processing Line Planning

- Sieving

- Mixing

- Vegetable Cleaning

- Vegetable Cutting

- Extracting

- Meat Mincing

- Seasoning

- Forming

- Sealing

- Solution Proposal

ANKO's Dumpling Production Solution to Solve Labor Shortages in Food Production

ANKO did

In this specific case, two workers with one Automatic Dumpling Machine can help the client's eatery stay competitive and enhance overall operational performance. ANKO's high-quality HLT series Dumpling Machine produces 2,000 to 12,000 pieces per hour. It allows you to set parameters to adjust the production volumes according to your orders.

ANKO can help you more

Furthermore, ANKO is capable of planning an integrated one-stop service for the Automatic Dumpling Production Line. The solution includes space requirements, layout design, manpower planning, installation and training services, and even recipe optimization, etc. All your dumpling production needs will be handled by ANKO's professional team from a single place.

For more information about our Dumpling Production Solution, please click Learn More or complete the form below.

- Machines

-

HLT-660B Multipurpose Filling & Forming Machine

Dough will be extruded into a dough tube with stuffing inside, then cut by different forming molds. Even though the machine principle is simple, it has broad applications to make various stuffed foods in both western and eastern styles. For example, pelmeni, pierogi, momo, empanada, calzone, and samosa are able to be produced by this Multipurpose Filling & Forming Machine. (Note: HLT-660 series is no longer available. Please contact us for the updated HLT-700 series.)

- Video

(Note: HLT-660 series is no longer available. Please watch the video about HLT-700 series and feel free to contact us for more information.) So far ANKO has customized near 1,000 molds for HLT-series. Only having three molds and three kinds of stuffing can create nine kinds of unique food products to sell. Trust ANKO, we are committed to helping customers add value to their brands and launch new products.

- Country

Taiwan

Taiwan Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Taiwan with advanced automated food production technology for making Dumplings, Potstickers, Noodles, Shumai, Scallion Pies, Steamed Custard Buns, Tapioca Pearls, and Sweet Potato Balls. We also offer integrated solutions for popular foods such as Baozi, Wonton, Spring Rolls, Pineapple Cakes, Xiao Long Bao, Tang Yuan, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Seasoned minced meat or vegetarian stuffing is wrapped in a wrapper made from flour and water. It's, then, folded in half like a half moon to form the so-called dumpling that is able to be cooked in boiling water, steamed, fried, and deep fried. In this day and age, dumpling is the major product in the groups of frozen food and ready meal. Along the Silk Road, dumpling recipes were passed on to Europe. For example, Eastern European pierogi, tortellini, Italian ravioli, Spanish empanada, etc. With different ingredients, the variants of dumpling have been fused with local foods.

- Handmade Recipe

-

Food Ingredient

For wrapper-All Purpose Flour/Water/Salt, For filling-Ground Pork/Cabbage/Scallions/Coriander

Making the wrapper

(1) Add all purpose flour, some water, and salt in a large bowl, and then stir them well. (2) Knead dough. In the process, add water little by little if needed until dough become smooth and elastic. (3) Cover with wet cloth and rest for one hour. (4) Divide dough into four equal portions. (5) Roll out each dough ball as thin as possible. (6) Apply a round cutter to cut out dumpling wrappers.

Making the filling

(1) Chop cabbage, green scallions, and coriander. (2) Mix them and minced pork together. (3) Keep stir the filling until viscous.

How to make

(1) Take a wrapper in the palm of one hand. (2) Scoop a teaspoon of filling on the center. (3) Smear water on the edge and fold it in half. (4) Press to seal off. (5) Pleat the sealed side and slightly press each fold.

- Downloads

English

English