ANKO Spring roll Production Line– Machinery Design for Jordanian Company

The owner purchased our HLT-series, PP-2, SD-97, SRP, and Automatic Maammoul and Moon Cake Production Line, full of confidence in ANKO's machines. After that, he decided to buy two spring roll production lines (SR-24) at a time, because it produces high-quality and uniform products and can be used in combination with the existing SRP-series to manufacture either pastry or spring roll. It is a massive and wise investment. (The SR-24 is no longer available. The new model is SR-27 machine.)

Spring roll

ANKO Team Research Problem Solving or Solution Delivery

How to determine the stickiness of stuffing which affect the depositor stability.

Spring roll stuffing can be made with meat, vegetable, or combination, even sweet flavor such as jam. Machine is not like human who has eye-hand coordination skill; it has to be adjusted according to stickiness so that the depositor can perfectly feed the same amount of stuffing in position. Otherwise, the stuffing may stick in the hopper or be loose after feeding. Take this case as an example; there are different levels of stickiness in cooked, frozen, or reheated beef stuffing.

The stuffing is too dry to be form into thick strips.

The stuffing with less fat becomes loose particles which cannot be formed as squeezing; by the same token, it may be loose yet compact as depositing by depositor.

Following ANKO's adjustments, we successfully resolved the stuffing issues, resulting in perfectly formed Spring Rolls. Operators only need to manually align the final products on the tray for the next procedure.

Food Equipment Introduction

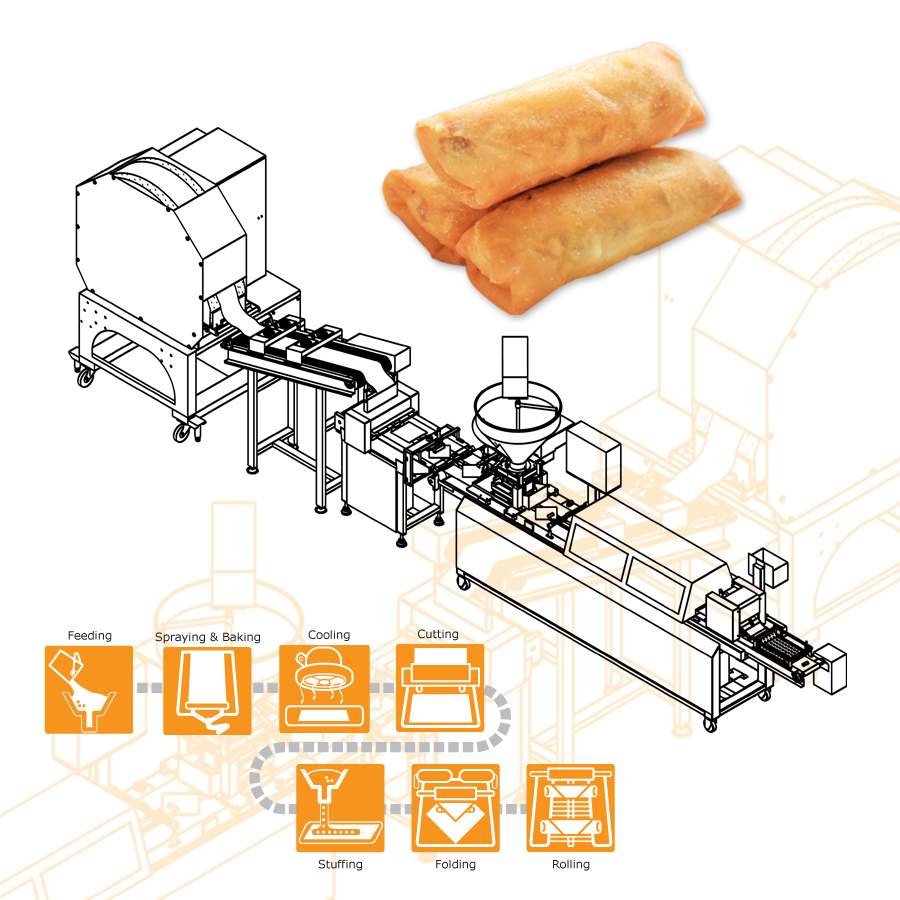

- Pour cooked stuffing into hopper.

- Pour mixed batter into batter tank.

- Set the temperature.

- Bake pastry belt.

- Cool pastry belt under fans.

- Cut pastry belt into 200mm*200mm square.

- Turn cut pastry in position, ready to be fed with stuffing.

- Deposit stuffing on a set place.

- Fold the first corner to the center to cover the stuffing, and then the left and right corner by side flappers.

- Apply batter on the last corner as glue.

- Roll toward the last corner under stainless steel net, at the same time, seal the end.

In combination with a cooling system, the nozzle will not be stuck as spraying batter on the baking drum.

Prior to the wrapping process, waiting for the pastry to be cooked and soften is necessary. As transforming handmade process into automated production, firstly, we tightly connect every step. Big baking drum bakes prepared batter into a pastry belt which is then cooled straightaway and cut into appropriate sized spring roll pastry. The depositor continues the next action non-stop to enhance efficiency. Secondly...

- Solution Proposal

Benefit Your Business with ANKO's Comprehensive Spring Roll Production Solution

ANKO did

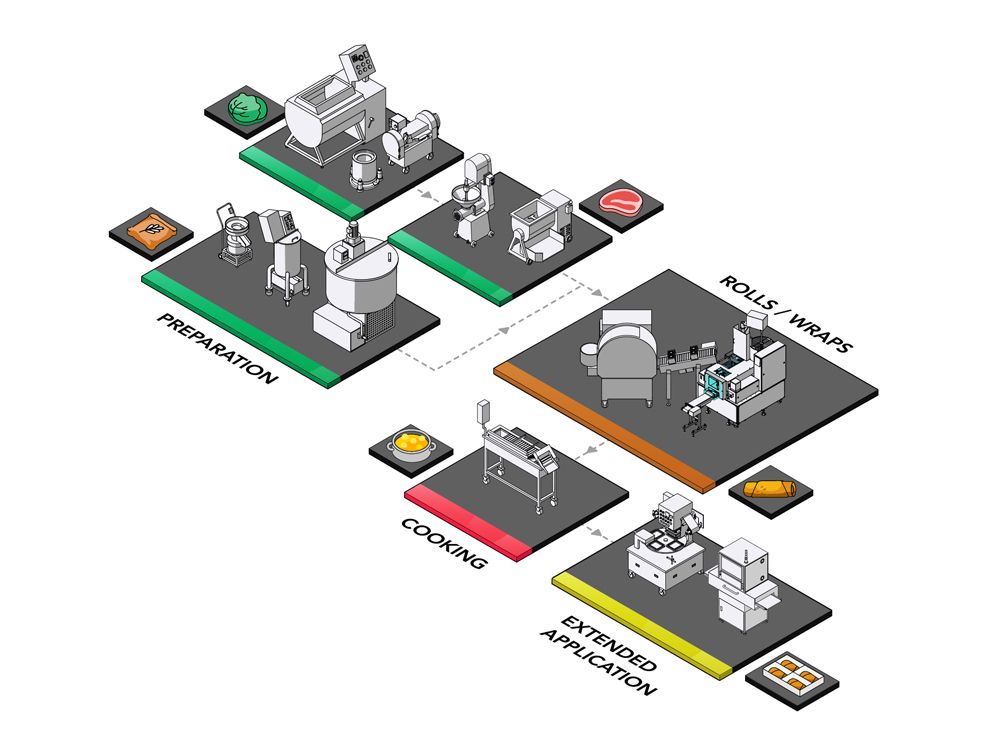

ANKO's Spring Roll Production Line is designed to handle a diverse range of ingredients, from beef stuffing, pure vegetables, mixed veggies and meat, to raw vegetables and sweet components like cheese, chocolate with banana, apple with cinnamon, and more. The advanced mechanism ensures that filling ingredients retain their original textures without excessive compression.

ANKO can help you more

Beyond the Spring Roll Production Line, ANKO offers a comprehensive solution that includes batter and fillings preparation equipment, rolling and forming machines, packaging solutions, cooking equipment, and even a food x-ray inspection machine, tailored to your specific requirements. This all-encompassing Spring Roll Production Solution is truly an asset to your food business.

For more information, please click Learn More or complete the form below and we will get back to you as soon as possible.

- Machines

-

SR-24

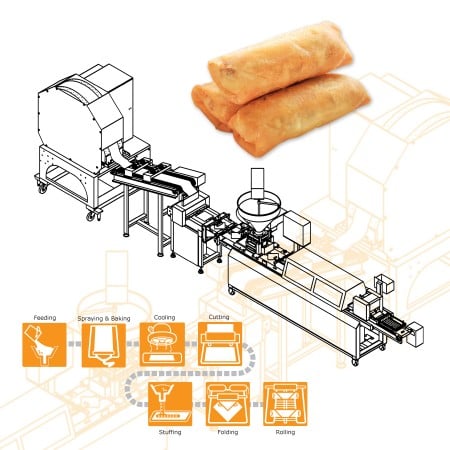

Preparing batter in advance and placing it overnight are better for the production. As starting machine, sprayer sprays batter on baking drum evenly. Through the parameter settings of pastry thickness and baking drum temperature, the spring roll texture and softness/hardness can be adjusted. Then, after cooling by fans, the pastry belt is cut out into pieces and ready to be conveyed to depositor. Pour prepared stuffing into stuffing hopper manually. It is deposited on pastry in position while sensor detects the pastry. The subsequent folding device folds three corners and the last corner is dotted batter as glue. Finally, the spring roll is formed while it's rolled through under a stainless steel net. The maximum capacity is 2,400 rolls in an hour. (The SR-24 is no longer available. The new model is SR-27 machine.)

- Video

Spring roll Production Line designed by ANKO is fully automatic to produce 2,400 spring rolls in one hour. After pouring well-stirred batter and stuffing, the automatic process starts from baking drum, cooling fans, cutter with sensor to innovative depositing, folding and wrapping devices. It is the ideal solution for making identical quality and tasty spring roll that can compete with handmade spring roll.

- Country

Jordan

Jordan Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Jordan with advanced automated food production technology for making Spring Rolls, Kubba Mosul Pastries and Kibbehs. We also offer integrated solutions for popular foods such as Maamouls, Arabic Breads, Samosas, Sambouseks, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

With globalization, the profound Chinese cuisine has evolved into a number of variants fused local ingredients and cultures. The evolution of spring roll is a typical example. In a square spring roll pastry, the stuffing can be any meats, vegetables or shredded local ingredients for creating a fusion cuisine. ANKO had successfully produced cheese spring roll by our spring roll production line. As for cooking, deep frying can boost crispy taste, whereas baking can be a healthier way to intake less oil. As fast food is prevalent, the easy cook and quick serve spring roll is also a choice for any occasion.

- Handmade Recipe

-

Food Ingredient

For pastry-All Purpose Flour/Water/Salt/Oil, For filling-Cabbage/Carrot/Ground Beef/Sesame Oil/Ginger/Garlic/Salt/Sugar/Pepper

Making the pastry

(1) Mix and stir flour, water, salt, and oil together. (2) Heat a frying pan. (3) Apply a brush to smear a thin layer of mixture in the pan. (4) As the edges of the pastry slightly peel off, flip it over to cook the other side for a few seconds.

Making the filling

(1) Shred cabbage and carrot, and then chop ginger and garlic. (2) Heat a wok, saute ginger and garlic, and then add cabbage shreds and carrot shreds, and then add ground beef. (3) Season with salt, sugar, and pepper. (4) Remove from pan and flavor with sesame oil.

How to make

(1) Scoop beef mixture and place it on a spring roll pastry. It is better to place it close to the edge. (2) To roll up the spring roll starts from the side with filling. (3) Roll half the pastry and then fold the left and the right sides toward the center. (4) Then, roll the pastry to the end. (5) Deep fry spring rolls and enjoy them with sauce.

- Downloads

English

English