Perfectly formed Xiao Long Bao! ANKO builds customized Xiao Long Bao Production Equipment for a Dutch client

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy recipes to catch customer's heart. With the increasing popularity of dim sum, he began running a food factory. As seeking food equipment, he knew that ANKO has years of experience in the dim sum making machinery and provides customization in accordance with individual needs and factory planning. Therefore, he decided to cooperate with ANKO.

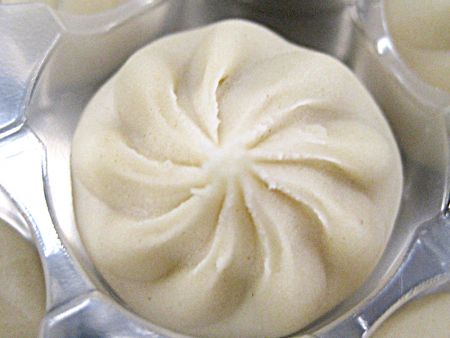

Xiao Long Bao (Tang Bao)

ANKO Team Research Problem Solving or Solution Delivery

How to solve the forming machine could not cut and form filled dough tube into individual xiao long baos?

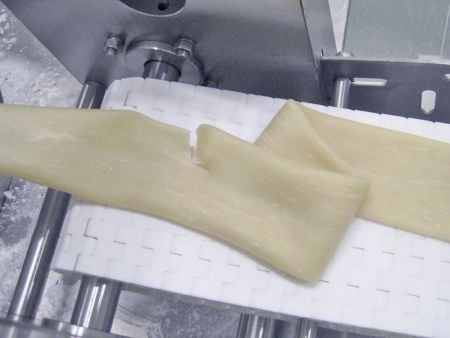

The recipes of handmade foods are not all suitable for machines to manufacture foods. For example, heat generated by machine operation makes dough warmer than that kneaded by hand. Therefore, the ingredients of dough need to be adjusted to prevent dough from degrading.

The problem in this case is that the xiao long baos could not be cut and formed. Our engineer extruded the dough tube to check the extensibility of the dough. He found the dough is too hard, so……(Please contact us to get more information)

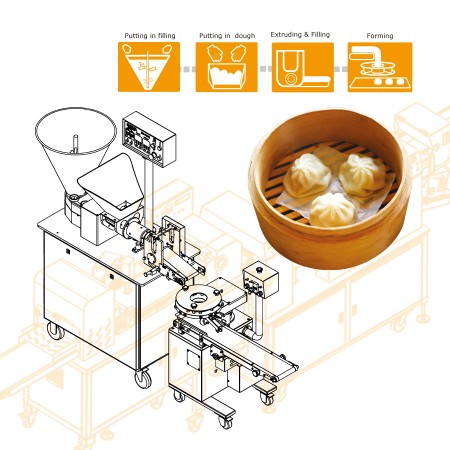

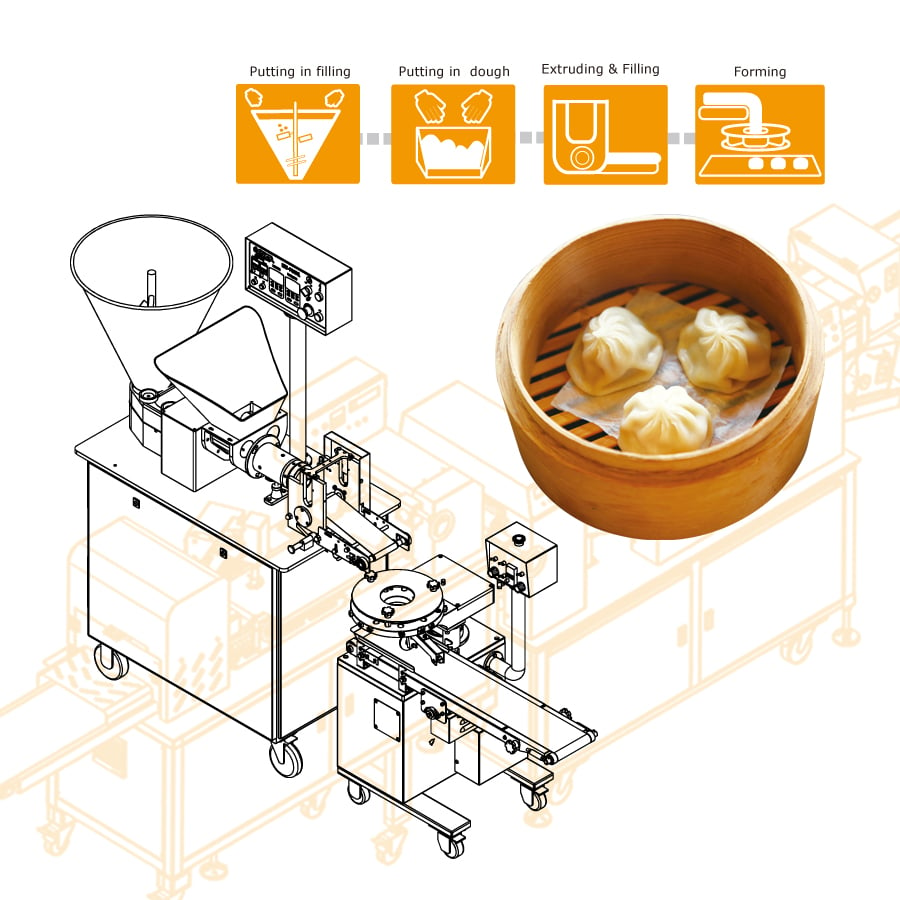

Food Equipment Introduction

- Put the filling into the filling hopper.

- Put the dough into the dough hopper.

- The cylindrical filling is extruded by the filling pipe of HLT-700XL.

- The dough tube is extruded by the dough pipe of HLT-700XL.

- The cylindrical filling is encrusted with the dough tube while they are formed.

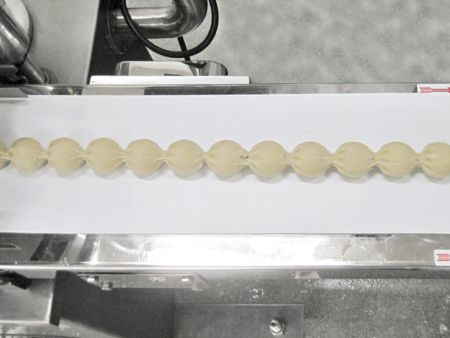

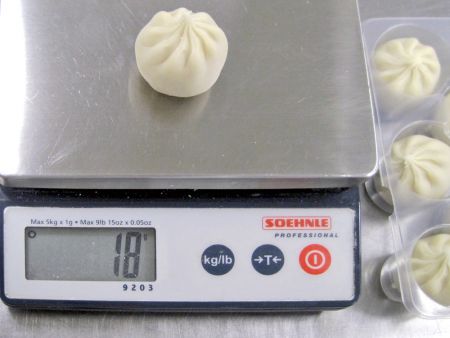

- The filled dough tube is cut and formed into individual xiao long baos with nine-fold pleat on top by the EA-100K forming machine. (the updated model: EA-100KA)

- The xiao long baos are continually steamed on a steam conveyor.

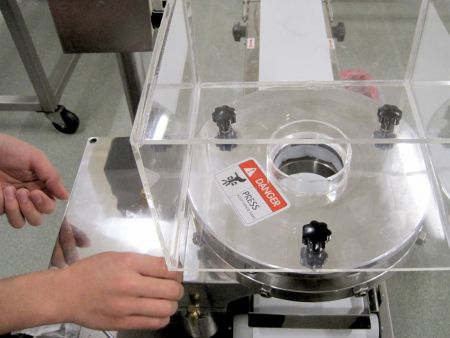

The shutter unit of the EA-100K forming machine is designed with great ingenuity to prevent dough from sticking.

In order to prevent dough from sticking, our engineers minimized the contact time and surface when the shutter unit cut and form the products. Although there is no doubt that the structure of the shutter unit has a significant impact on production, the shutter speed is the key to success. At the moment the shutter opens and closes, a product is formed perfect and pleasing. (Note: EA-100K is no longer available. The updated model is EA-100KA. Please feel free to contact us for more information.)

- Solution Proposal

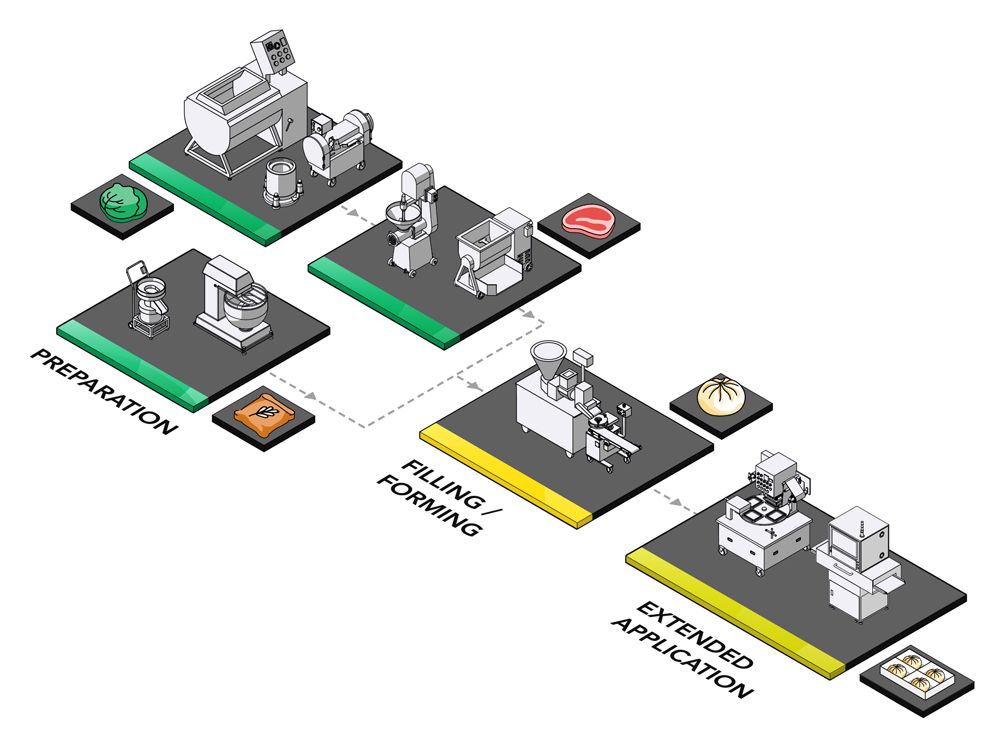

ANKO provides the ultimate automated Xiao Long Bao production Solutions

ANKO did

ANKO configured the HLT-700XL Multipurpose Filling and Forming Machine and the EA-100K Forming machine to create a highly efficient Xiao Long Bao production line to supply this client’s increased product requirements.

ANKO can help you more

ANKO can also supply clients with packaging equipment and X-Ray inspection machines to increase the productivity and safety of their retail products. The X-Ray inspection machine detects foreign objects in packaged food products which increases food safety and consumer confidence.

If you are interested in more information about ANKO machines, please click Learn More or fill out the inquiry form below.

- Machines

-

HLT-700XL

The HLT-700XL Multipurpose Filling & Forming Machine extrudes the filling into the dough tube and the filled dough tube is formed into desired shapes with different molds. The principle of the HLT-700XL is simple and widely applied in producing a variety of filled foods such as pelmeni, pierogi, momo, empanada, calzone, samosa, etc.

EA-100K

EA-100K is for producing round or oval products. Through the shutting action of the shutter unit, the filled dough tube is divided into equal products with or without pattern on top. (Note: EA-100K is no longer available. The updated model is EA-100KA. Please feel free to contact us for more information.)

- Video

The shutting action of EA-100K shutters – The machine equips with pattern shutters in this video. The filled dough pipe is continuously conveyed to EA-100K and cut off as required through the shutting action of shutters. (Note: EA-100K is no longer available. The updated model is EA-100KA. Please feel free to contact us for more information.)

Xiao Long Bao with thin wrapper and meat-and-vegetable filling can be automatically produced by food equipment. Simply put the dough and filling into the hoppers, the Multipurpose Filling & Forming Machine can automatically extrude the filling into the dough tube. Then, the Forming Machine cuts and pinches pleats on the top of the xiao long baos, which only needs one second.

- Country

Netherlands

Netherlands Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Netherlands with advanced automated food production technology for making Dumplings, Xiao Long Bao, Har Gow and Roti. We also offer integrated solutions for popular foods such as Empanadas, Loempia (Spring Rolls), Kibbeh, Samosas, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Xiao Long Bao (小籠包) are also known as Soup Dumplings, meaning a “small steamer basket bun;” it is a classic Chinese Dim Sum that is slightly smaller than regular meat buns. These dumplings are steamed and usually filled with tasty meat juices, hence their name,“Soup Dumplings.” Most Soup Dumplings are made with a thin wrapper filled with ground pork and vegetable filling; the wrappers are usually so thin that after steaming it becomes translucent. Soup Dumplings are often served with fresh juliennes of young ginger and a dipping soy sauce. Some people also enjoy it with a dash of Chinese rice vinegar. A world-famous Xiaolong Soup Dumpling company based in Taiwan; they are known for their 18-fold pleated Xiaolong Soup Dumplings. The expansion of their restaurants has introduced Soup Dumplings to the world, and it has inspired a new Dim Sum trend in recent years. Restaurants and food companies have now created various flavors of Soup Dumplings, including wrappers tinted with natural food dye from fruits and vegetables, and fillings made with ingredients such as luffa, spinach, black truffle, pumpkin squash, cheeses, crab meat, squid, and foie gras, to attract consumer’s attention.

In order to meet the vegetarian and vegan consumer market, many food companies are using plant-based meat substitutes to make meatless Soup Dumplings that taste similar to regular Soup Dumplings. Many other vegetarian or vegan Soup Dumplings are made with luffa, tofu, cabbage, and mushrooms, and are delicious. Currently, frozen and ready-to-cook Soup Dumplings are available for purchase at many local supermarkets, large chain stores, and online shopping platforms worldwide, especially in the United States, England, and New Zealand. Consumers enjoy Soup Dumplings and also because they can be heated at home with a steamer, microwave, or instant pots.- Handmade Recipe

-

Food Ingredient

For Wrapper-All Purpose Flour/Warm Water, For Filling-Ground Pork/Salt/Sesame Oil/Sugar/Soy Sauce/White Pepper/Minced Ginger/Shaoxing Wine/Aspic

Making the Filling

(1) Add ground pork, salt, sesame oil, sugar, soy sauce, white pepper, minced ginger, shaoxing wine in a large bowl and mix them together thoroughly. (2) Roughly chop the aspic and add into the bowl. (3) Gently stir the aspic and the filling together. (4) Refrigerate the mixed filling when preparing the dough of xiao long baos.

Making the Wrapper

(1) Take another mixing bowl. (2) Add all-purpose flour and warm water into the bowl. (3) Stir them well and knead the dough until smooth. (4) Cover the bowl with a cloth and rest the dough for 30 minutes. (5) Roll the dough into a cylinder. Then, divide it into 8-gram dough balls. (6) Roll out each dough ball into a round wrapper.

How to make

(1) Take out the filling. (2) Place a spoon of the filling in the middle of the wrapper. (3) Pinch and pleat the wrapper to seal the filling. (4) Steam xiao long baos in a steamer.

- Downloads

English

English