Food Processing Equipment Solutions

View our new food processing machine and turnkey solutions

English

English

English

English 日本語

日本語 Português

Português Français

Français Español

Español 한국어

한국어 Deutsch

Deutsch العربية

العربية فارسی

فارسی Türkçe

Türkçe Indonesia

Indonesia Polska

Polska ไทย

ไทย Việt

Việt українська

українська Русский

Русский Suomen

Suomen Nederlands

Nederlands Azərbaycan

Azərbaycan Беларуская

Беларуская Български

Български বাঙ্গালী

বাঙ্গালী česky

česky Dansk

Dansk Ελληνικά

Ελληνικά Eesti

Eesti Gaeilge

Gaeilge हिन्दी

हिन्दी Hrvatska

Hrvatska Magyar

Magyar Italiano

Italiano Lietuviškai

Lietuviškai Latviešu

Latviešu Bahasa Melayu

Bahasa Melayu Română

Română slovenčina

slovenčina Svenska

Svenska Filipino

Filipino

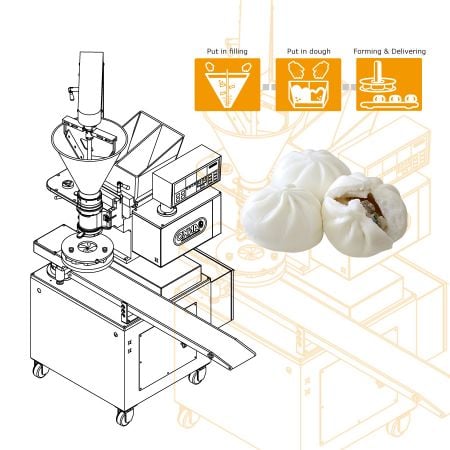

The client, a Chinese entrepreneur who moved to the Netherlands, started a restaurant specializing in authentic dumplings, famous for thin wrappers and generous fillings appealing to both the local Chinese community and Dutch customers. As the restaurant grew and expansion plans emerged, the client experimented with buns, producing them manually to test market demand. Positive feedback encouraged larger-scale production. Facing increasing orders and limited manpower, the client leveraged their experience with ANKO’s HLT-700XL machine and introduced the SD-97W Automatic Encrusting and Forming Machine, efficiently increasing output, maintaining consistent quality, and offering a wider variety of products for in-store dining and retail.

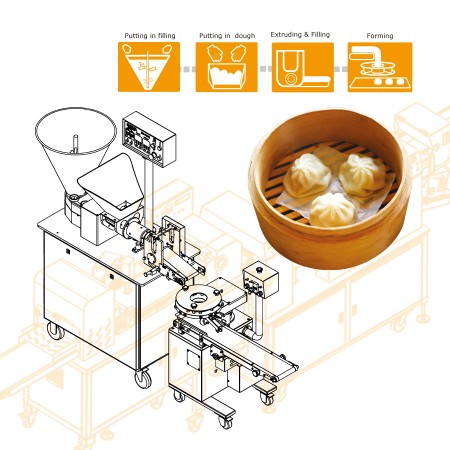

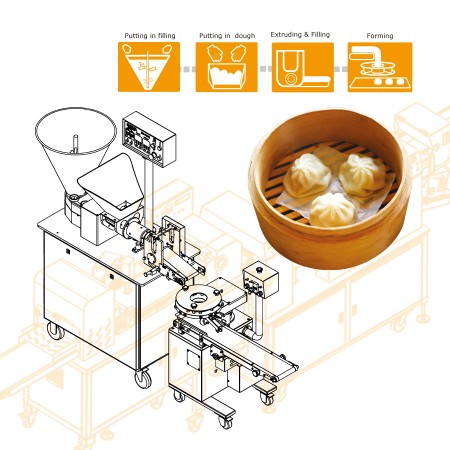

Production automation is inevitable in the food manufacturing industry, and ANKO aims to "assist manufacturers in achieving high production automation goals." In 2024, we launched the "Xiao Long Bao Integrated Production Line" as an integration concept to connect various related production parts. Within a year, ANKO successfully launched the world's first Xiao Long Bao Production Line, supported by our "automated food production solutions" system to further increase food production efficiency and reduce overall labor requirements. ANKO ensures that smart technology is applied to your food production process to increase product quality, consistency, and taste to provide competitive advantages.

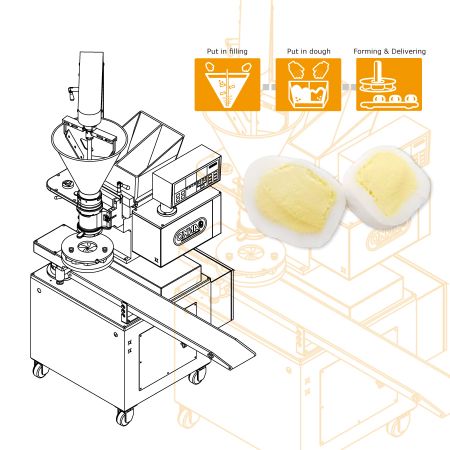

An ANKO client operates a restaurant in Los Angeles serving authentic Asian specialty foods, and Mochi is one of their best-selling desserts. Many diners enjoy ending their meals with an order of Mochi, often paired with tea or coffee. Our client wanted to increase their revenue by making their popular Mochi available for takeout, but they didn’t have enough labor to accomplish this plan. While searching for automated food machine options, this client discovered ANKO Food Tech and scheduled a machine trial. ANKO recommended using the SD-97W Automatic Encrusting and Forming machine to the client for making Mochi and Mochi Ice Cream. The client was very impressed with the machine demonstration, and the taste of the final products. Based on their volume, they decided to purchase the SD-97SS Table-Type model. After delivering the machine, our team helped the client to familiarize themselves with the production process, machine maintenance routines, and overall operations.

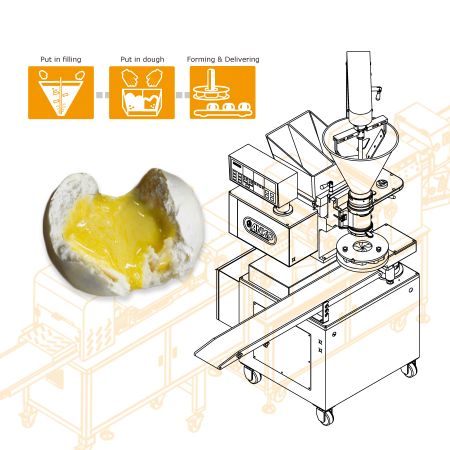

The dining group operates Cantonese restaurants, hot pot buffets, and Japanese buffets for satisfying various consumers. They used to make their food products by hand. With more and more restaurants opened, the continuing growth in demand for steamed custard buns in all types of their restaurants prompted the company to invest in a new machine to extend its offerings. it's a turn to transform handmade into automatic production. Chefs hoped to maintain food quality while cutting cost so that they found ANKO. We have the largest market share in Taiwan food machine industry and our machine can help them meet the growing demand. After testing our SD-97W, they are satisfied with the multifunctional encrusting and forming machine which offers them the flexibility in production. In addition to steamed custard bun mentioned above, they also use the machine to produce sesame balls.

The client started his business by opening a restaurant in Netherlands, serving dim sum dishes. He studied the Dutch flavor and healthy recipes to catch customer's heart. With the increasing popularity of dim sum, he began running a food factory. As seeking food equipment, he knew that ANKO has years of experience in the dim sum making machinery and provides customization in accordance with individual needs and factory planning. Therefore, he decided to cooperate with ANKO.

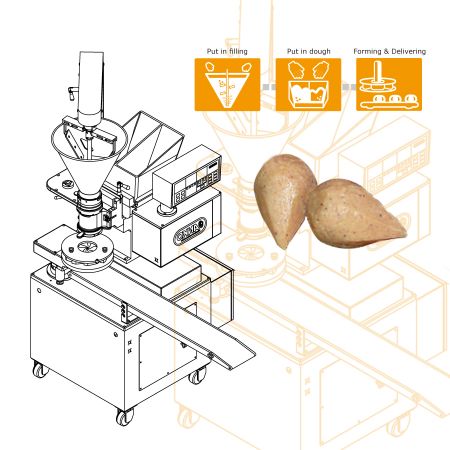

The company provides frozen food for numerous hotels and villages in Cairo, Egypt. Consumers can also buy their products online, in supermarkets or deli. Selling products in multi sales channel had leaded to an increasing demand, so the company's owner, via a dealer, had been looking for a supplier who can offer an automated production solution for making kubba. It's always a challenge to make a machine work well with a new recipe. In this case, we had a problem in forming kubba because the crust was too sticky. The just formed kubba would stick to the shutter unit and then be broken while the shutter unit opened. Through recipe and temperature adjustment, ANKO team solved the problem successfully.

The company owns a Cantonese restaurant serving handmade dim sum. With business growth, a lack of supply and problems with staff management had come out. It took an average of three months for a new employee to become fully productive. Therefore, the client started finding an automatic solution. At first, the client knew ANKO by searching from the Internet and visiting IBA Munich, which is a trade show held in Germany every two years, but he didn't contact us until the next IBA Munich. He placed an order without having a machine trial because he thought ANKO had considerable experience in food machinery. He purchased an HLT-700XL Multipurpose Filling and Forming Machine and an EA-100KA Forming Machine. With these two machines, he could make a wide variety of dishes, such as dumpling, steamed dumpling, crystal dumpling, fun guo, soup dumpling, increase production capacity and decrease labor costs. Moreover, when ANKO's engineer conducted on-side commissioning, our engineer helped solve his problem that soup dumplings had no soup.