Croquetas (Croquette) Automatic Production Line Design for an Indonesia Company

An ANKO client having had a successful food business in Colombia selling croquetas (croquette) to casinos and other retailers was looking for an opportunity to turn a vacant factory in Indonesia into a profitable automated food business. Because this client had previously purchased ANKO’s HLT-700XL, SR-24 and an ANKO commercial deep fryer, they had decided to seek ANKO’s assistance to provide them with professional automated production line equipment and support to sell croquetas (croquette) in Indonesia.

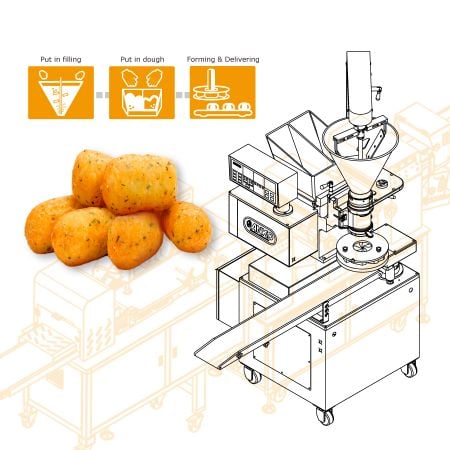

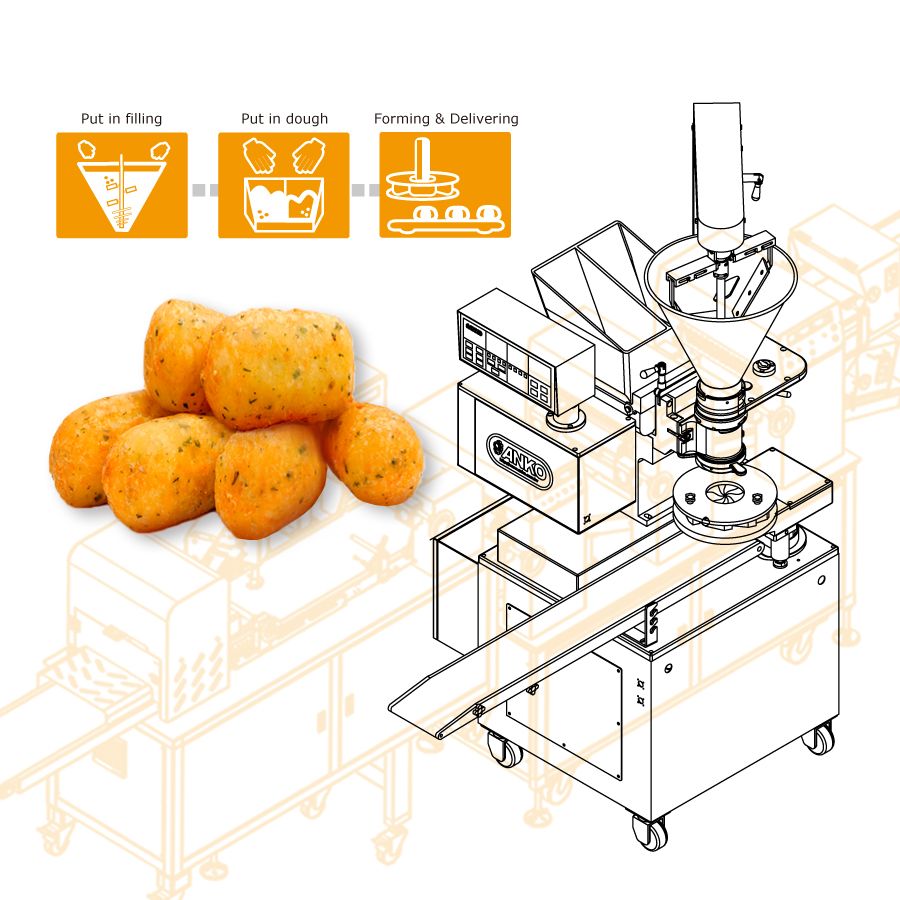

Croquetas (Croquette)

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Solutions to Prevent Product Forming Breakage and Bursting after Frying

To prevent product breaking or bursting during the production or frying process, ANKO’s team had come up with creative and effective solutions for both of these problems.

When producing Croquetas (Croquette) with corn batter, overnight refrigeration and temperature fluctuation can cause condensation and excess fluids in the batter. This situation can change the original viscosity and consistency affecting the end product. Through research, the ANKO solutions team discovered the best way to prevent this problem is to……(Please contact us to get more information)

Solution 2. Extendable Conveyor Belt for Dispensing Products into Deep Fryer

For more efficient production, ANKO recommended an extendable conveyor belt with censors for dispensing the Croquetas (Croquette) evenly into the deep fryer. This ensures each product is fried at the same temperature and time and will have the same texture and consistency. Additionally, this conveyor system also prevented products from stacking and sticking.

Solution 3. Production Line Set Up from Scratch

This client's factory space in Indonesia utilizes local employment and ANKO's expertise. ANKO managed the new automated production line planning, installation, and set-up including procurement for mixing equipment, SD-97W Automatic Encrusting and Forming Machine, and a commercial deep fryer, ANKO also provided product recipes and production fine tuning services to ensure the corn batter is made into the right consistency for coating and forming, thus keeping the Croquetas (Croquette) intact after deep frying. ANKO's goal is to help our clients achieve smooth and successful mass production with a low defect rate.

Solution 4. Safety Circuit for Regions with Unstable Power Supply

This Indonesian factory is located in a suburban area where the power supply is unstable and power shortages and blackouts happen frequently, especially in the summertime and after thunderstorms. ANKO’s engineers have added a safety circuit to this production line to ensure when there is a sudden power shortage or outage the production machines will immediately shut down. The machines will not restart automatically, but only with manual inputs to ensure proper operational safety and human supervision.

ANKO completed the Indonesian Croquetas (Croquette) production line from planning to installation and then onto production. ANKO provided our client with a turn-key successful and profitable automated food production business.

Food Equipment Introduction

- Loading hopper with filling mixture

- Loading hopper with premixed dough

- Filling and Forming products with SD-97W

- Product transferred onto conveyor belt

- Product dispensing into deep fryer

- Complete deep frying process

The ANKO SD-97W can process a wide range of traditional hand-made food recipes.

The SD-97W Automatic Encrusting and Forming Machine has the capacity of processing a wide range of food ingredients with different moisture content, viscosity, and textures. This includes sticky rice, ground meats, and different types of doughs and fillings including dry peanut powder added to moist ground meats. The parameter settings are fully adjustable and can be fine-tuned for each recipe.

In the case of the Indonesian Company, cooked corn puree (grits) is used to encrust a viscos rice and potato filling. The SD-97W has achieved successful results with its special extruding mechanism providing delicious products that exceeded our client's expectations.

- Solution Proposal

One-stop Croquetas (Croquette) Production Solution for a Profitable Automated Food Business

ANKO did

In this specific case, ANKO helped the client set up a complete Croquetas Production Line, from front-end to back-end equipment, to meet their market demand. This not only saves your time searching for and inquiring about Automatic Croquetas machines but also allows you to acquire all the equipment from a single source.

ANKO can help you more

Additionally, ANKO offers advice on your Croquetas recipes, production, and strategies for your target market based on our general knowledge. Depending on your needs, our food experts can adjust the thickness of the Croquetas wrapper, the amount of filling, and the texture. We can also assist in planning your factory layout, staff management, and optimizing the production process.

For more inofrmation, please click Learn More or submit an inquiry directly.

- Machines

-

SD-97W

ANKO’s SD-97W Automatic Encrusting and Forming Machine is designed to produce a wide range of food products. There are many standard and patterned molds that can be used to form products into various shapes and sizes, such as Baozi (stuffed buns), cookies and falafel. The parameters of this machine are fully adjustable and can save up to 5 memorized product settings. At the Indonesian company, a standard mold was used to encrust rice filling into the corn puree and formed into Croquetas (Croquette).

It also includes a built-in Internet of Things (IoT) system to ensure that the production can be overseen remotely with a mobile device. Besides, a maintenance reminder program is installed to ensure consistent productivity.The system automatically detects the parts that require maintenance and send alerts; this can lower risks and repair costs while providing our clients with more time to focus on food production.

Mixing Machine

This automatic spiral mixer or vertical dough mixer is certified food grade safe, easy to use, and highly efficient. The stainless-steel mixing bowl rotates while mixing the ingredients to simulate hand kneading products. In this case of the Indonesian Company, it is used to mix cooked corn puree until the desired viscosity is reached and ready for production.

Extendable Conveyor Belt

This extendable conveyor belt system is designed with an independent sensor and the length of the conveyor is adjustable for different food dispensing purposes. In this particular case, it is used for dispensing raw Croquetas (Croquette) into the deep fryer allowing the products to be cooked evenly.

Deep Fryer

This deep fryer is made with safety in mind and is easy to operate. It is designed with two layers of conveyor belts within the fryer for maneuvering products while cooking them in hot oil. The digital temperature control system helps maintain steady frying heat and has a built-in Power Failure Protection system to safeguard the handlers.

- Country

Indonesia

Indonesia Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Indonesia with advanced automated food production technology for making Croquetas (Croquette), Siomay (Shumai) and Fish Balls. We also offer integrated solutions for popular foods such as Spring Rolls, Dumplings, Mochi, Meat Balls, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Croquetas (Croquette) originated in France and were introduced to Indonesia by the Dutch. As a result, the Indonesians used the Dutch name “Kroket” instead of Croquetas (Croquette). In Indonesia, Krokets are one of the most widely consumed savory snacks. The most popular Croquetas (Croquette) or “Kroket” flavor is chicken, also known as “Kroket Ragout Ayam” which is made with chicken and potato skins, then coated with breadcrumbs and deep-fried. The crispy potato crust and soft chicken filling is delicious and a country-wide favorite. Nowadays, there are many more creative Croquetas (Croquette) flavors in Indonesia such as “Kroket Rendang”.

- Handmade Recipe

-

Food Ingredient

For Croquette Crust-Corn puree (grits) /Water, For Filling-Cooked rice/Potato/Parmesan cheese/Parsley/Garlic

Making Croquette Crust

Remove the dry corn kernels and boil with water, then drain and grind the kernels into coarse mill puree and use the vertical mixer to mix the corn puree until the texture becomes sticky.

Making the Filling

(1) Combine cooked rice, boiled potato dices and mixed with seasonings. (2) Shape the rice and potato filling into a ball, coat it with corn batter, and then deep-fry each croquette until it is golden brown and crispy.

- Downloads

English

English