ANKO Food Lab: Ready-to-eat Tapioca Pearl Recipe Development for a Taiwanese Company

This Taiwanese client had started their business in canned food production for export, mainly sold to North America, Australia and New Zealand, but recently discovered the increasing tapioca pearl demand worldwide, and the client has many existing customers who are owners of shave ice and tea/beverage shops. This Taiwanese client had no experience in tapioca pearl production and originally wanted to find an OEM but was referred by the OEM company to consult with ANKO. After ANKO’s team had successfully developed the tapioca pearl products the client had desired to produce, they purchased ANKO’s GD-18B Automatic Cutting and Rounding Machine which is currently in production.

Ready-to-eat Tapioca Pearls (Boba)

ANKO Team Research Problem Solving or Solution Delivery

Solution 1. Maintain original Boba’s chewy texture after Pasteurization

Pasteurization is necessary for eliminating micro bacterial growth in canned foods, but the client would like to avoid the negative effects on the final products from high heat. ANKO’s recipe research and developers went to ANKO’s FOOD LAB and tested……(Please contact us to get more information)

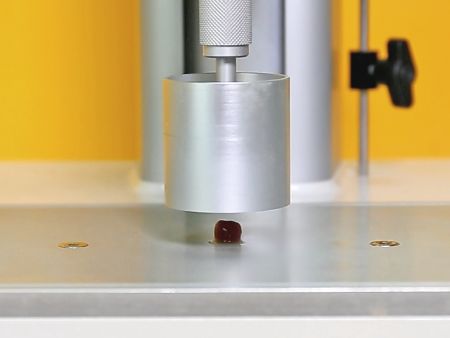

After undergoing high temperature and pressure testing, the tapioca pearls retained their appearance

Solution 2. ANKO’s FOOD LAB tests on different physical properties to ensure the tapioca pearls remain the same consistency after heating.

This client had requested to develop recipes for ready-to-eat tapioca pearls that are chew after reheating. ANKO’s FOOD LAB tests various physical properties of the food products and ingredients, as well as different recipe ratios and mechanical production mechanisms to achieve the ultimate product results for our clients. In this case, the tapioca pearls were tested in different temperatures and 2 recipes reached our client’s expectations.

The elasticity, hardness, and chewiness of the tapioca pearls were successfully customized to meet customer requirements

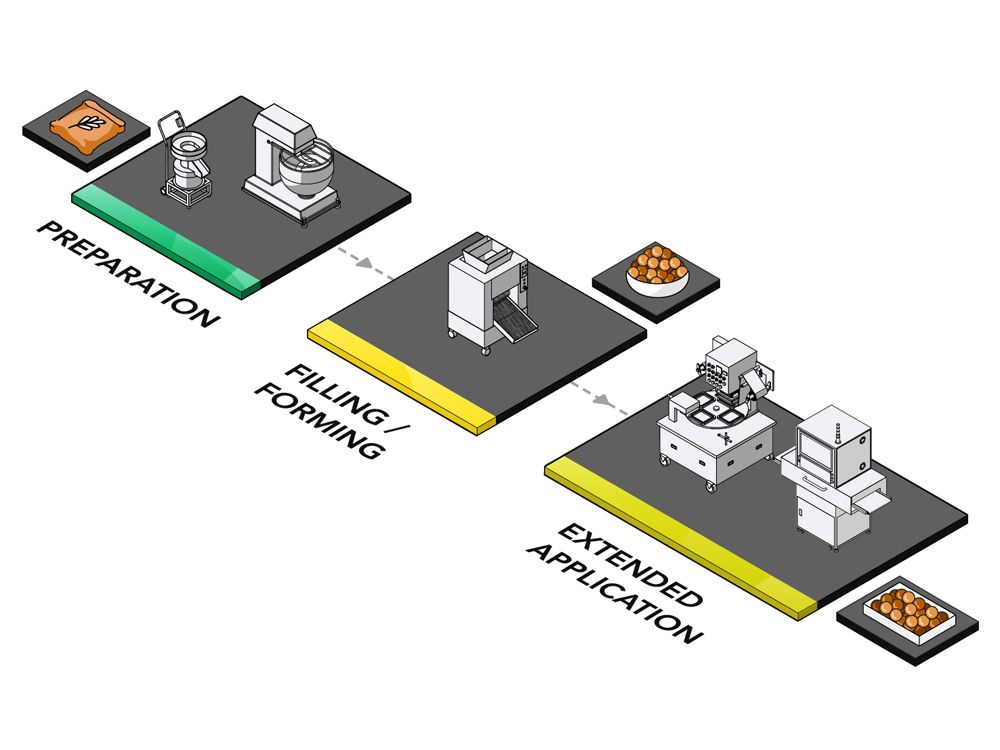

Solution 3. ANKO provides one-stop solution for production line installation and operational training

ANKO’s Food Lab is located in the Taipei headquarters. In this case, ANKO’s team assisted a client who did not have any equipment or experience in tapioca pearl production with recipe development and used physical tests to achieve the desired texture the client requested. The client initially purchased 2 GD-18B and 2 more after their production expanded. ANKO provided operational manuals for the equipment, production clips, trouble shooting, maintenance as well as onsite training programs were scheduled to help accelerate the process of production and new product launching, and be more cost efficient.

In this case, ANKO Food Lab helps client to customize tapioca pearls production services with specific recipe and production equipment. The client is satisfied with texture, color, size, and package of tailor-make tapioca pearls.

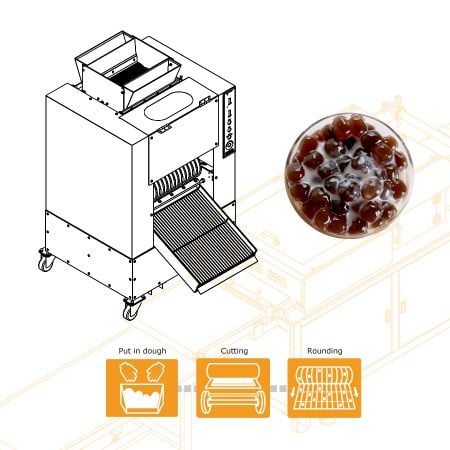

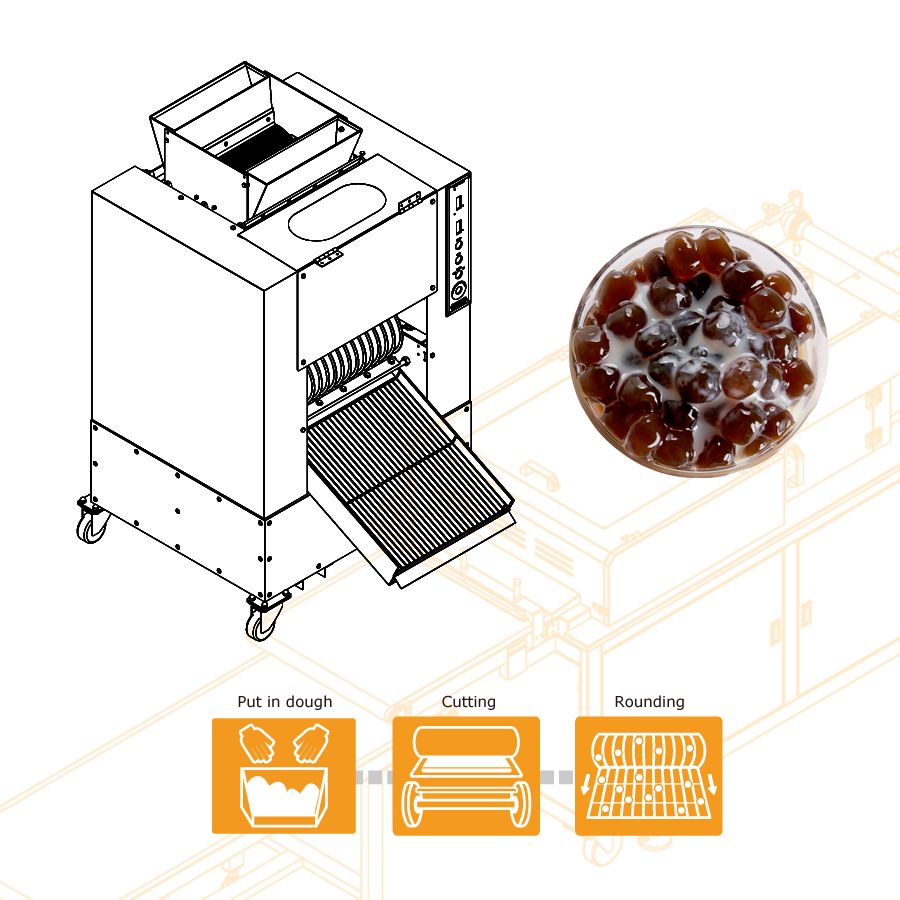

Food Equipment Introduction

- Placing tapioca dough into the hopper

- Use GD-18B to cut and form tapioca pearls

- Final products gathered in tray

- Solution Proposal

Welcome To ANKO's Food Lab. The Recipe Generator For Successful Food Businesses.

Are you considering transitioning your current food production from manual to fully automated manufacturing to save time and labor cost, but do not yet have the suitable recipes and knowhow? Or are you concerned about the food products’ quality and taste will not be the same as when they are machine made? ANKO is the pioneer food machine company that has advanced machinery technology and in-depth recipe research and development experience, we have conducted an array of scientific food analysis, test reports and client interviews, we have successfully helped setup thousands of food production facilities and have established a database with over 700 authentic traditional and ethnic food recipes from around the globe. At the ANKO Food Lab, our team of experts will guide you to find the best food production equipment, recipes and help optimize your production processes, as well as consultancy and thorough after sales services, so, together we can turn your food ideas into viable business opportunities.

Besides GD-18B Automatic Cutting and Rounding Machine, ANKO can also offer Dough Mixer, Packaging Machine and Food X-Ray Inspection Machine to help our clients build a Complete Tapioca Pearls Production Line. Based on your requirement, our team can provide you with the best production solution for your Bubble Tea Business.

If you’re interested in more information, please click Learn More or feel free to fill out the form below, and we will get back to you as soon as possible.

- Machines

-

GD-18B

ANKO’s GD-18B Automatic Cutting and Rounding Machine is compact in size and can process many different types of dough into a wide range of spherical products such as tapioca pearls (boba), tangyuang (rice dumplings), taro balls, sweet potato balls, chocolate balls, pills and fish pellets (boilies). GD-18B has the productivity range from 30kg – 180kg per hour, it’s suitable for food factories, central kitchens, cloud kitchens, restaurants, as well as tea shops and bakeries.

- Video

- Country

Taiwan

Taiwan Ethnic Food Machine And Food Processing Equipment Solutions

ANKO provides our clients in Taiwan with advanced automated food production technology for making Dumplings, Potstickers, Noodles, Shumai, Scallion Pies, Steamed Custard Buns, Tapioca Pearls, and Sweet Potato Balls. We also offer integrated solutions for popular foods such as Baozi, Wonton, Spring Rolls, Pineapple Cakes, Xiao Long Bao, Tang Yuan, and more. Our professional team assists clients with a smooth transition from manual to automated manufacturing to enhance their production efficiency and consistency.Every ANKO success story showcases how we support our clients in their automated manufacturing food business, from food preparation and machine procurement to production line design to troubleshooting and after-sales service.Please feel free to click on the following successful case studies to discover how we can work together to optimize your food production.

- Category

- Food Culture

Bubble Milk Tea (or Boba Milk Tea) is one of the most popular tea drinks in the world that originated in Taiwan in the 1980s. Recently bubble tea drinks had been rated as one of the most delicious drinks in the world, the tapioca pearls (boba) added chewiness and fun to the tea drinks; brown sugar is the original flavor, but now there are also matcha (Japanese green tea), blueberry and other flavors being developed. Innovative ways of adding tapioca pearls to foods include adding them onto pizzas, into cheesecakes and popsicles.

- Handmade Recipe

-

Food Ingredient

Cassava Starch/Modified Starch/Brown Sugar/Water

How to make

(1) Mix cassava starch with brown sugar (2) Place mixture onto a bamboo woven tray (3) Sprinkle water (4) Rounding starch into small pearl sized balls (boba)

- Downloads

English

English